Method for preparing SrZr03:Ce nanometer powder with composite coprecipitator

A nano-powder and co-precipitant technology, applied in the field of nano-powder preparation, can solve the problems of unsuitability for industrial production, high equipment requirements, low output, etc., and achieve the effect of short cycle, low raw material cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

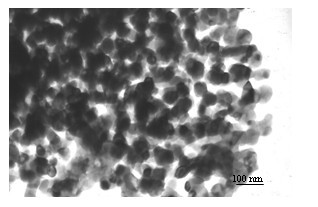

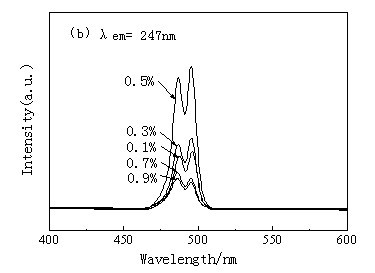

Embodiment 1

[0024] Put 0.471g Sr(NO 3 ) 2 , 0.704g ZrOCl 2 ·8H 2 O and 0.005gCe(NO 3 ) 3 Mix and dissolve in alcohol-water solution (the ratio of ethanol and water is 1:3), and make a metal salt solution with a concentration of 0.1mol / L. The concentration of ammonia water is 0.5mol / L, the concentration of ammonium bicarbonate is 0.3mol / L as the mixed precipitant, and the concentration of PAM (polyacrylamide) is 1.8×10 -3 mol·L is a dispersant. Drop the mixed precipitant and dispersant into the prepared metal salt solution successively, titrate at a rate of 3ml / min, until the pH=11~12, and stir with a magnetic stirrer. After the titration, aging for 2h, filter with distilled water Wash three times, detect the filtrate with silver nitrate until there is no chloride ion, wash twice with absolute ethanol, dry in a drying oven at 80°C for 24 hours, grind, pass through a 100-mesh sieve, and place in a muffle furnace Calcined at 1000°C for 2 hours and ball milled to obtain SrZr with a pri...

Embodiment 2

[0026] Put 0.979g Sr(NO 3 ) 2 , 1.349g ZrOCl 2 ·8H 2 O and 0.009gCe(NO 3 ) 3 Mix and dissolve in alcohol-water solution (the ratio of ethanol and water is 1:3), and make a metal salt solution with a concentration of 0.2mol / L. The concentration of ammonia water is 0.5mol / L, the concentration of ammonium bicarbonate is 0.3mol / L as the mixed precipitant, and the concentration of PAM (polyacrylamide) is 1.8×10 -3 mol·L is a dispersant. Drop the mixed precipitant and dispersant into the prepared metal salt solution successively, the titration speed is 3ml / min, until the pH=11~12, and stir with a magnetic stirrer. Wash three times, detect the filtrate with silver nitrate until there is no chloride ion, wash twice with absolute ethanol, dry in a drying oven at 80°C for 24 hours, grind, pass through a 100-mesh sieve, and place in a muffle furnace Calcined at 1000°C for 2h and ball milled to obtain SrZr with a particle size of about 50nm, nearly spherical shape and good dispersi...

Embodiment 3

[0028] Put 1.539g Sr(NO 3 ) 2 , 1.918g ZrOCl 2 ·8H 2 O and 0.014gCe(NO 3 ) 3 Mix and dissolve in alcohol-water solution (the ratio of ethanol and water is 1:3), and make a metal salt solution with a concentration of 0.3mol / L. The concentration of ammonia water is 0.5mol / L, the concentration of ammonium bicarbonate is 0.3mol / L as the mixed precipitant, and the concentration of PAM (polyacrylamide) is 1.8×10 -3 mol·L is a dispersant. Drop the mixed precipitant and dispersant into the prepared metal salt solution successively, the titration speed is 3ml / min, until the pH=11~12, and stir with a magnetic stirrer. Wash three times, detect the filtrate with silver nitrate until there is no chloride ion, wash twice with absolute ethanol, dry in a drying oven at 80°C for 24 hours, grind, pass through a 100-mesh sieve, and place in a muffle furnace Calcined at 1000°C for 2h and ball milled to obtain SrZr with a particle size of about 55nm, nearly spherical shape and good dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com