Vehicle overloading detecting system

A detection system and vehicle technology, applied to vehicle parts, tractors, motor vehicles, etc., can solve the problems of poor durability, large error, high sensor requirements, etc., to prevent vehicle overloading, convenient installation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

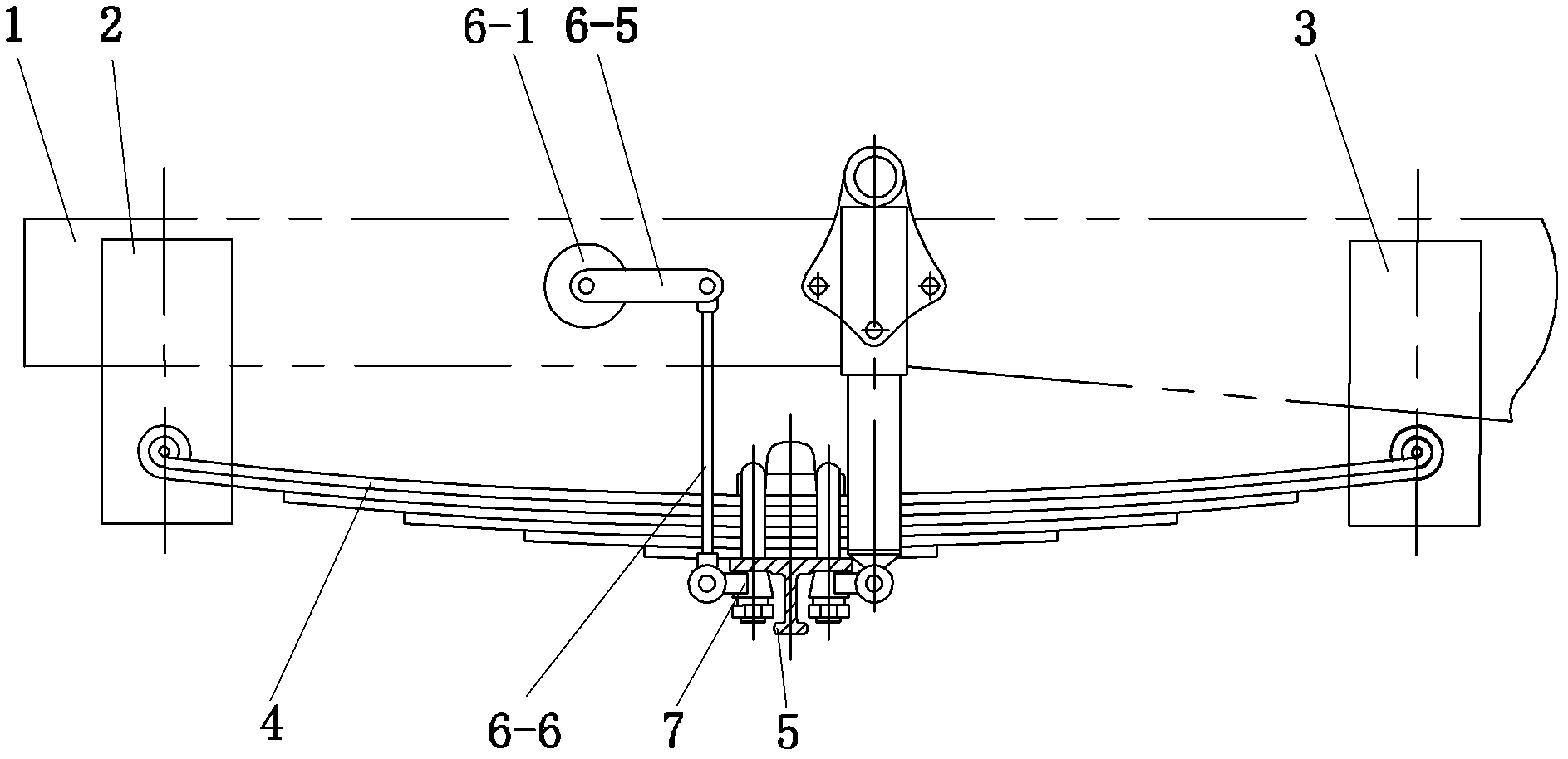

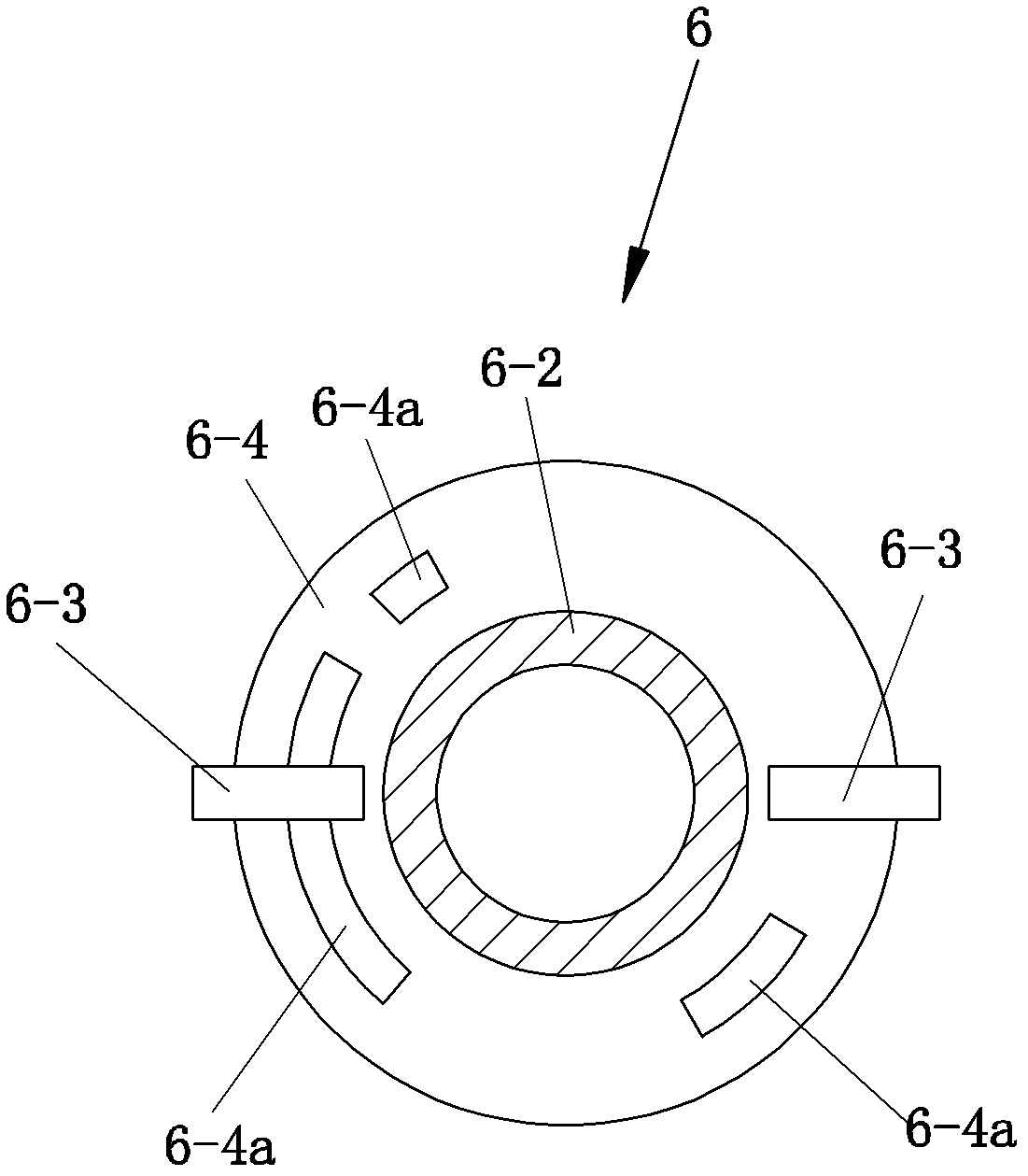

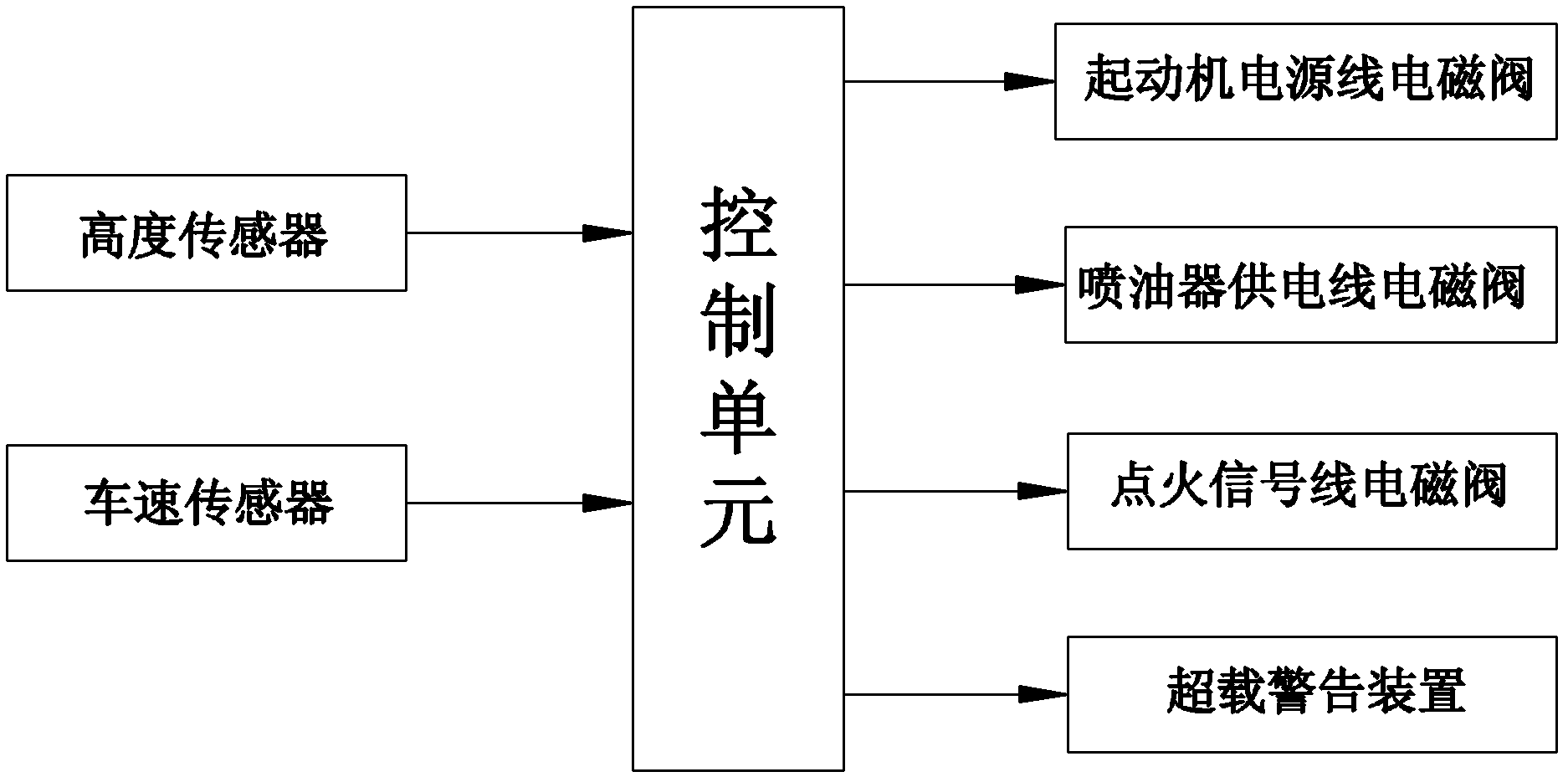

[0013] See figure 1 and figure 2 , the present embodiment comprises a vehicle frame 1, a front bracket 2, a rear bracket 3, a leaf spring 4 and an axle 5, the leaf spring 4 is fixed on the axle 5, and the front and rear brackets 2 and 3 are respectively connected to the vehicle frame 1 The front and rear ends of the leaf spring 4 are respectively connected to the front and rear brackets 2,3. A height sensor 6 is arranged between the axle 5 and the vehicle frame 1, and the height sensor 6 has a housing 6-1, a rotating shaft 6-2, two photocouplers 6-3, a masking disc 6-4, and a connecting rod. Rod 6-5 and pull rod 6-6; the housing 6-1 is fixed on the vehicle frame 1, the rotating shaft 6-2 is supported by a pair of bearings installed on the housing 6-1, and the shading disc 6-4 is located in the housing 6-1 and fixed on the rotating shaft 6-2. Three light-transmitting grooves 6-4a with unequal intervals and different lengths are arranged on the shielding disk 6-4. The two pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com