Drying channel of coating machine

A technology of coating machine and drying tunnel, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc. It can solve the problems of affecting the drying cycle, high temperature at the impact point, and poor air circulation flow. Achieve the effect of improving air circulation, avoiding hedging, and improving the leveling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

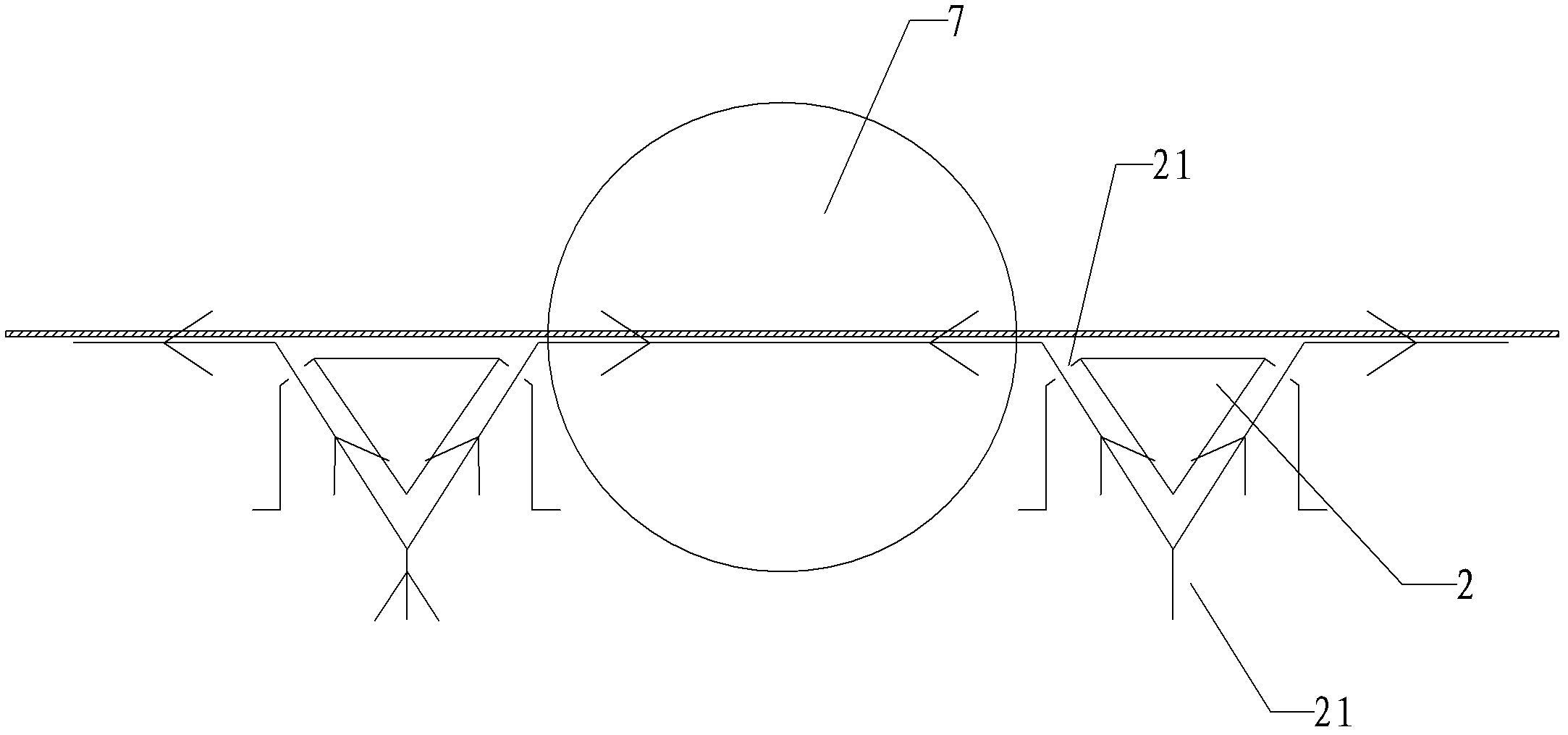

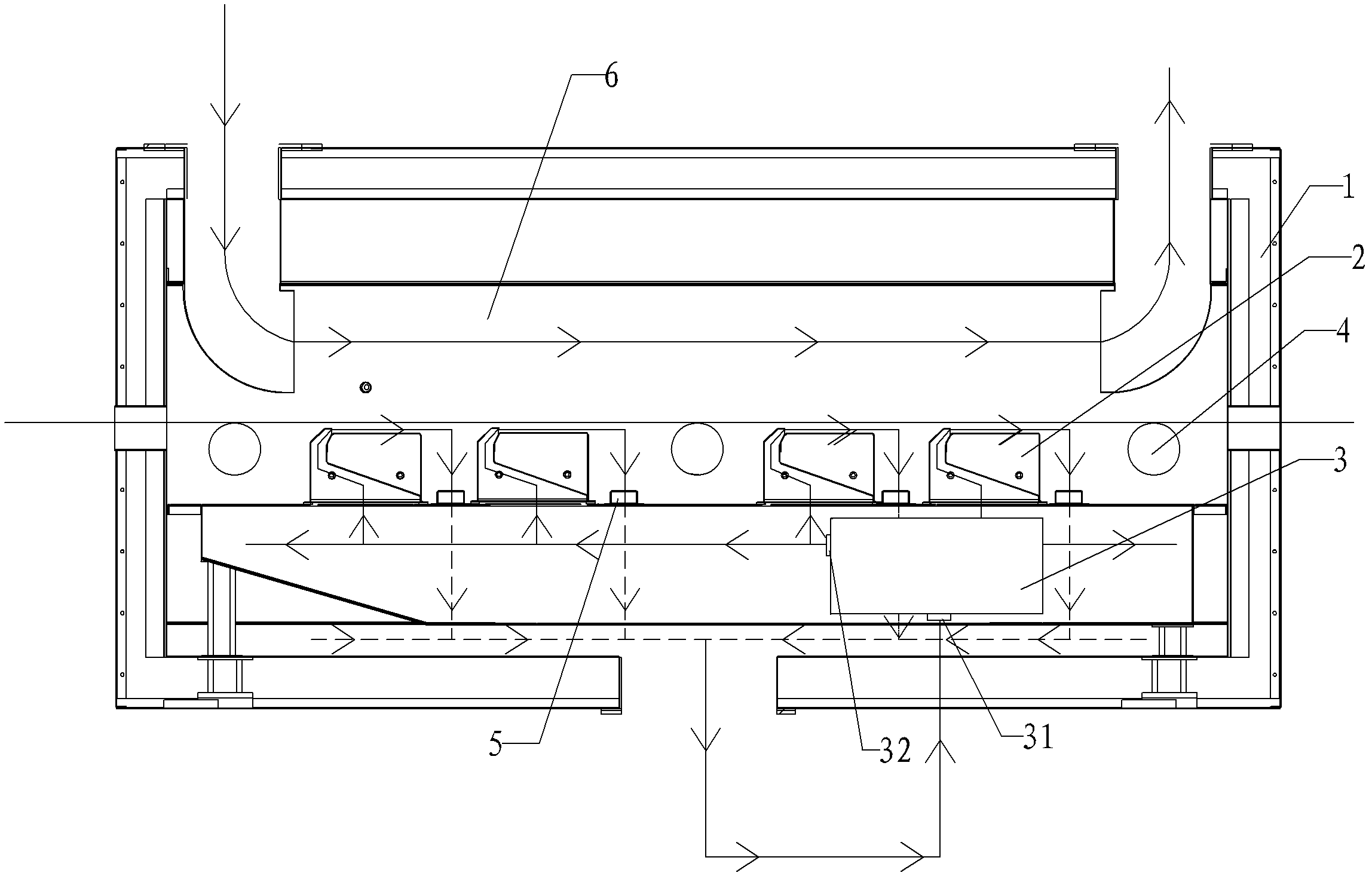

[0025] Refer to attached figure 2 and attached image 3 , as shown in the accompanying drawings, the present invention provides a coating machine drying tunnel, which is used to dry the substrate coated with slurry, including:

[0026] Drying tunnel body 1;

[0027] A transmission device, which transmits the substrate to be dried through the drying channel body 1;

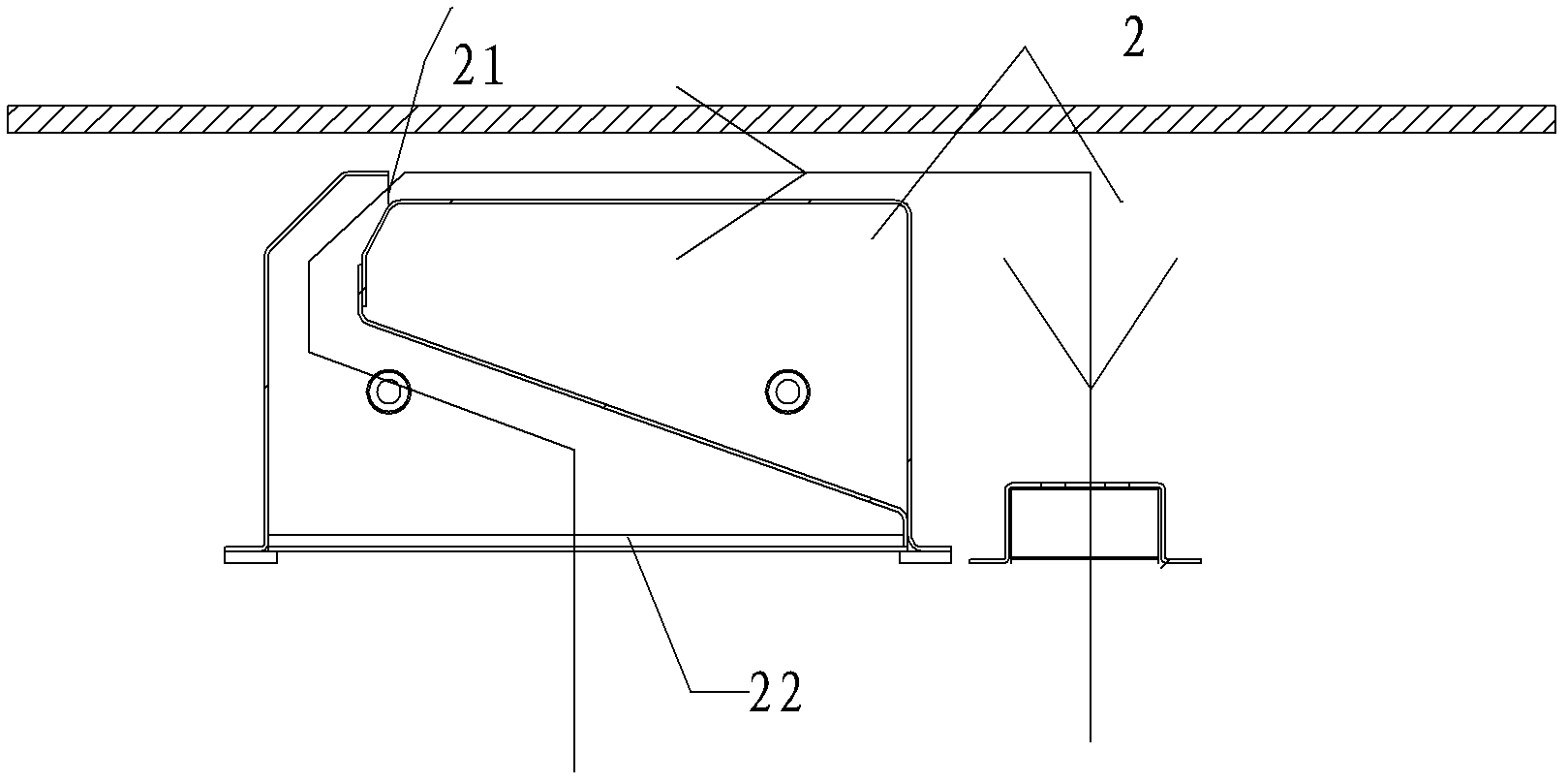

[0028] At least one drying tunnel air nozzle 2 is installed in the drying tunnel body 1 and arranged below the substrate driving roller 4 along the substrate driving direction, which includes an air outlet 21 and an air inlet 22;

[0029] The hot air blower 3 includes a fan air inlet 31 and a fan air outlet 32 , and the fan air outlet 32 communicates with the air inlet 22 of the air nozzle 2 of the drying tunnel.

[0030] The hot air blower 3 delivers hot air to the air nozzle 2 of the drying tunnel, and the hot air blown out from the air outlet 21 of the air nozzle 2 of the drying tunnel is parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com