Modified pumice absorbing material and preparation method as well as application thereof

An adsorption material, pumice technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult practical application, low adsorption activity, small red mud particle size, etc. The raw materials are easily available and the raw materials are widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

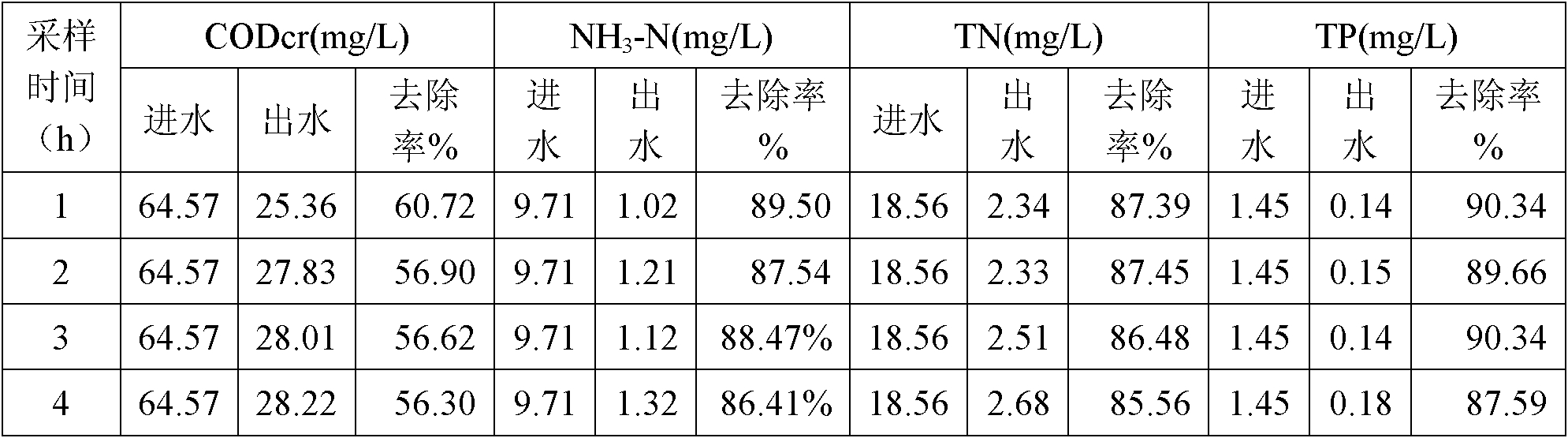

Examples

Embodiment 1

[0032] The preparation process of modified pumice adsorption material of the present invention is:

[0033] Prepare modified pumice adsorbent: the pumice (the pumice in the following examples is the same as this example) produced by the selected Yunnan Tengchong Volcanic Pumice Factory is obtained through crushing, sieving, and grinding to obtain a sieving particle size of 2~5mm pumice particles, and 500g Pumice particles were soaked and pickled by adding 1000ml of nitric acid solution with a concentration of 1.0mol / L for 4 hours, filtered and washed with water until the pH of the filtrate was 6.5, and the filter residue was dried at 95°C for 3 hours, and then roasted at 600°C for 6 hours. After cooling, the pumice adsorbent to be modified is obtained;

[0034] Preparation of red mud impregnation solution: the red mud produced by the Bayer process of China Aluminum Industry Zhongzhou Branch Company (the red mud in the following examples is the same as this example, and the red...

Embodiment 2

[0037] The preparation process of modified pumice adsorption material of the present invention is:

[0038]Preparation of modified pumice adsorbent: crush, sieve, and grind the selected pumice to obtain pumice particles with a sieving particle size of 2 to 5mm, add 1000g of pumice particles to 1000ml of 0.1mol / L nitric acid solution for soaking and pickling, soak Filter after 2 hours, wash with water until the filtrate pH=7.5, dry the filter residue at 90°C for 4 hours, then roast at 550°C for 4 hours, and cool naturally to prepare the pumice adsorbent to be modified;

[0039] Preparation of red mud impregnation solution: add 4000g red mud to 1000ml 0.1mol / L nitric acid solution, react for 30min and filter to obtain red mud impregnation solution;

[0040] Pumice modification: Put the pumice adsorbent to be modified into the red mud immersion liquid, place it in a vibrating water bath and soak it at 60°C for 4 hours for modification treatment, add 1000g of the pumice adsorbent ...

Embodiment 3

[0042] The preparation process of modified pumice adsorption material of the present invention is:

[0043] Preparation of modified pumice adsorbent: crush, sieve, and grind the selected pumice to obtain pumice particles with a sieving particle size of 2 to 5 mm, add 750 g of pumice particles to 1000 ml of 0.5 mol / L nitric acid solution for soaking and pickling, soak Filter after 3 hours, wash with water until the pH of the filtrate = 7.0, dry the filter residue at 92°C for 3.5 hours, roast at 575°C for 5 hours, and cool naturally to prepare the pumice adsorbent to be modified;

[0044] Preparation of red mud impregnation solution: add 4500g red mud to 1000ml 0.5mol / L nitric acid solution, react for 60min and filter to obtain red mud impregnation solution;

[0045] Pumice modification: Put the pumice adsorbent to be modified into the red mud immersion solution, place it in a vibrating water bath and soak it at 70°C for 6 hours for modification treatment, add 750g of the pumice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com