Water boiling device

A water boiler and water tank technology, which is applied in the field of high-power group-type fast-heating water boilers, can solve the problems that affect the performance and life of electric heating elements, the ultrasonic generator is large, and it is difficult to achieve scale inhibition and descaling. Mechanical effect, good scale inhibition and descaling effect, good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

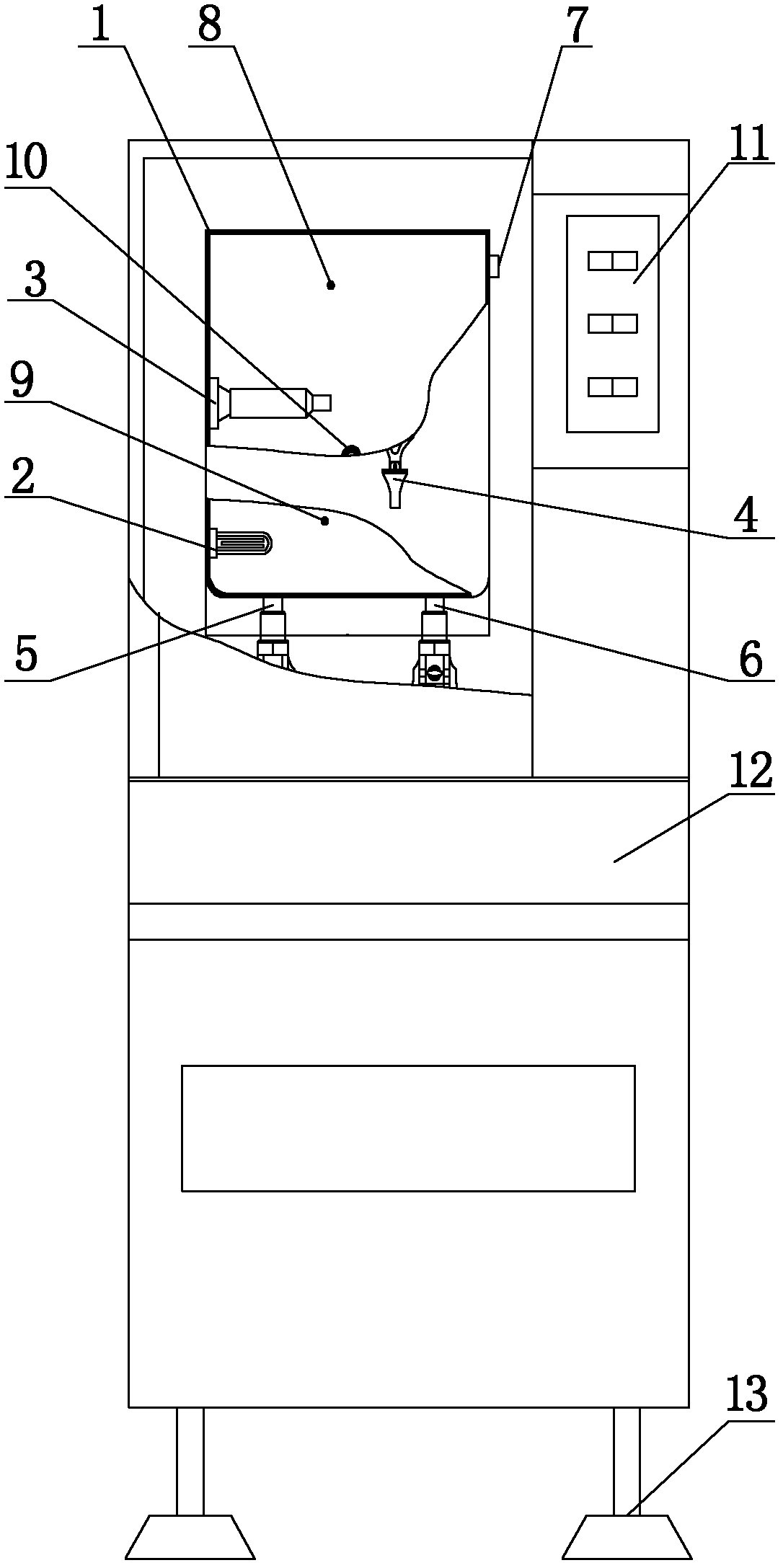

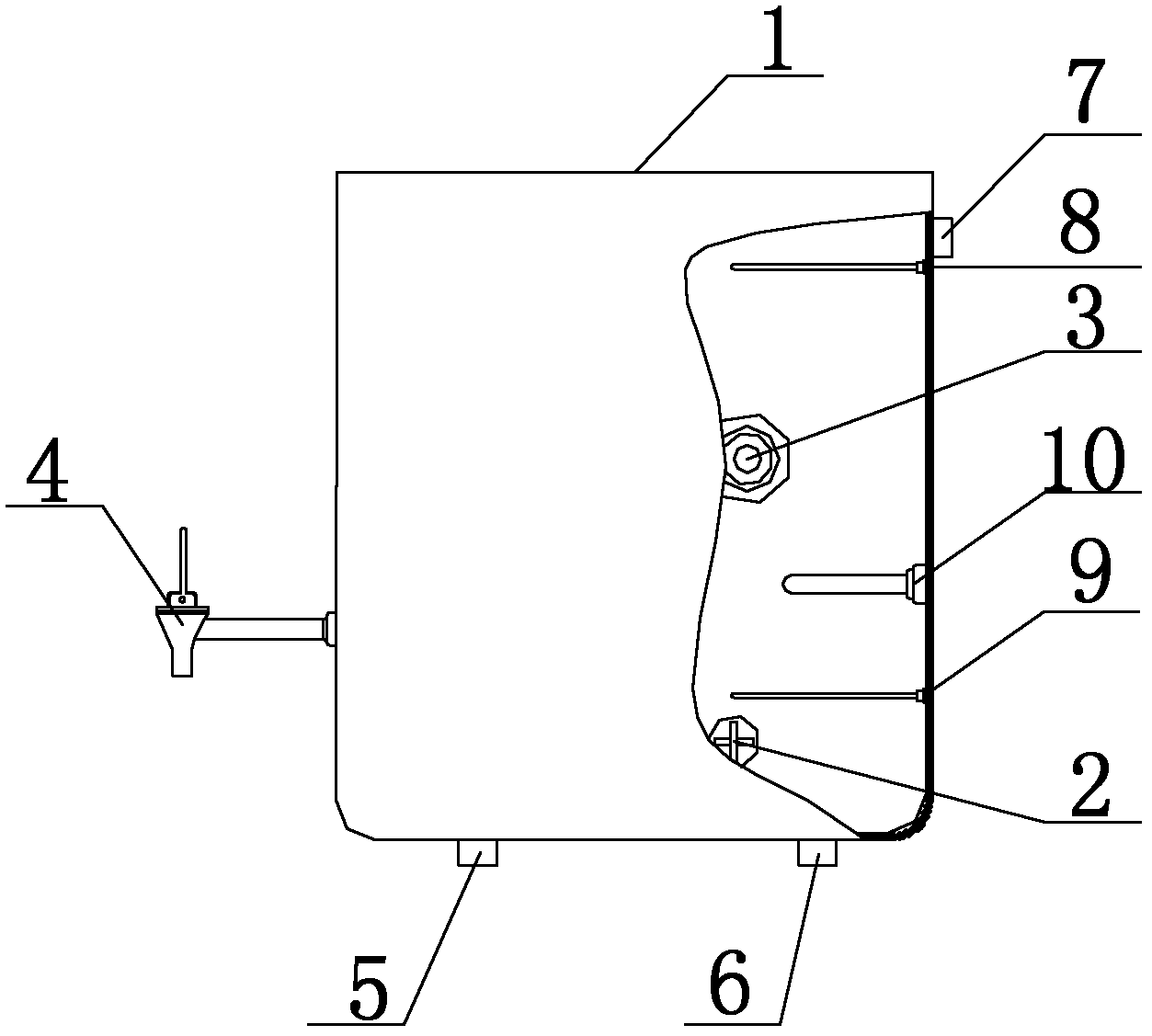

[0038] The structure of the boiler is as Figure 1-3 As shown, among them, the electric heating element 2 is made of ceramic electric heating element, which is made by wrapping resistance wire with ceramic material, forming, hot pressing sintering and mechanical processing; it can withstand high temperature of 1300°C. The ultrasonic generator 3 selects a 20kHz, 1000W ultrasonic generator, which continuously acts on 20L of water within 20 minutes. The water discharged from the faucet 4 is boiled water, and the temperature reaches 95°C. It takes 3 minutes to boil the water when the whole water boiler is running for the first time. After boiling, the power is not turned off, and boiling water is provided at any time. In order to check the effect, the water is connected to detect the change of the water after 20 minutes of ultrasonic operation. Through the detection of 500MHz nuclear magnetic resonance spectrometer, it is shown that the half-peak width of oxygen in water molecules...

Embodiment 2

[0041] The structure of the boiler is as Figure 1-3 As shown, among them, the electric heating element 2 is made of ceramic electric heating element, which is made by wrapping resistance wire with ceramic material, forming, hot pressing sintering and mechanical processing; it can withstand high temperature of 1300°C. The ultrasonic generator 3 selects a 30kHz, 700W ultrasonic generator, which continuously acts on 20L of water within 20 minutes. The water released from the faucet 4 is boiled water, and the temperature reaches 95°C. It takes 3 minutes to boil the water when the whole water boiler is running for the first time. After boiling, the power is not turned off, and boiling water is provided at any time. In order to check the effect, the water is connected to detect the change of the water after 20 minutes of ultrasonic operation. The detection by 500MHz nuclear magnetic resonance spectrometer shows that the half width of oxygen in water molecules is reduced from 125.86...

Embodiment 3

[0044] The structure of the boiler is as Figure 1-3 As shown, among them, the electric heating element 2 is made of ceramic electric heating element, which is made by wrapping resistance wire with ceramic material, forming, hot pressing sintering and mechanical processing; it can withstand high temperature of 1300°C. The ultrasonic generator 3 selects a 40kHz, 200W ultrasonic generator, which continuously acts on 20L of water within 20 minutes. The water released from the faucet 4 is boiled water, and the temperature reaches 95°C. It takes 3 minutes to boil the water when the whole water boiler is running for the first time. After boiling, the power is not turned off, and boiling water is provided at any time. In order to check the effect, the water is connected to detect the change of the water after 20 minutes of ultrasonic operation. Show by nuclear magnetic detection, the half peak width of the oxygen in the water molecule is reduced to 102.41MHZ by 125.86MHZ, compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com