Touch pad sensor

A touch panel and sensor technology, used in instruments, electrical digital data processing, and data processing input/output processes, etc., can solve problems such as inability to ensure electrical conductivity, and achieve high reliability and excellent durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

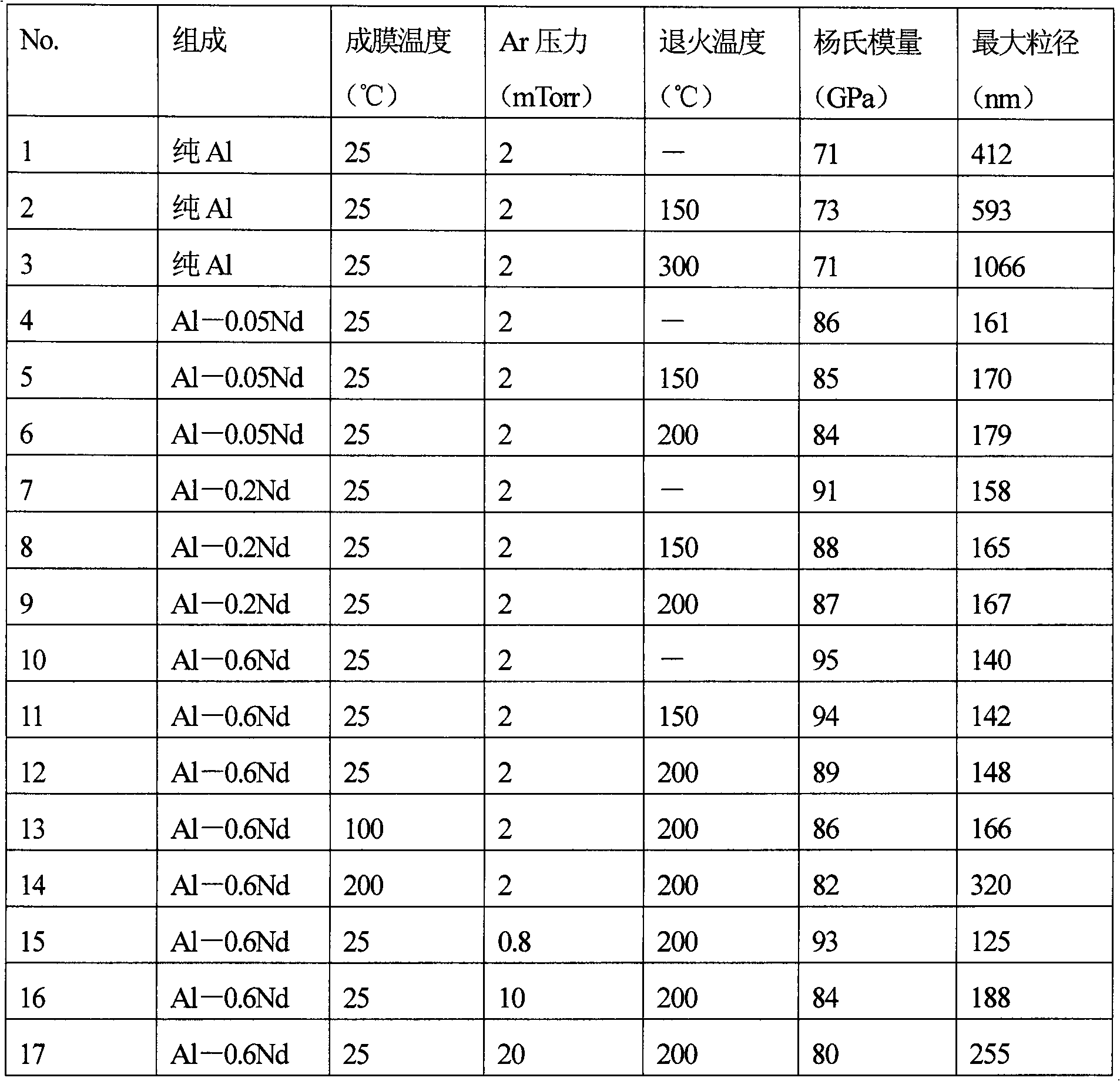

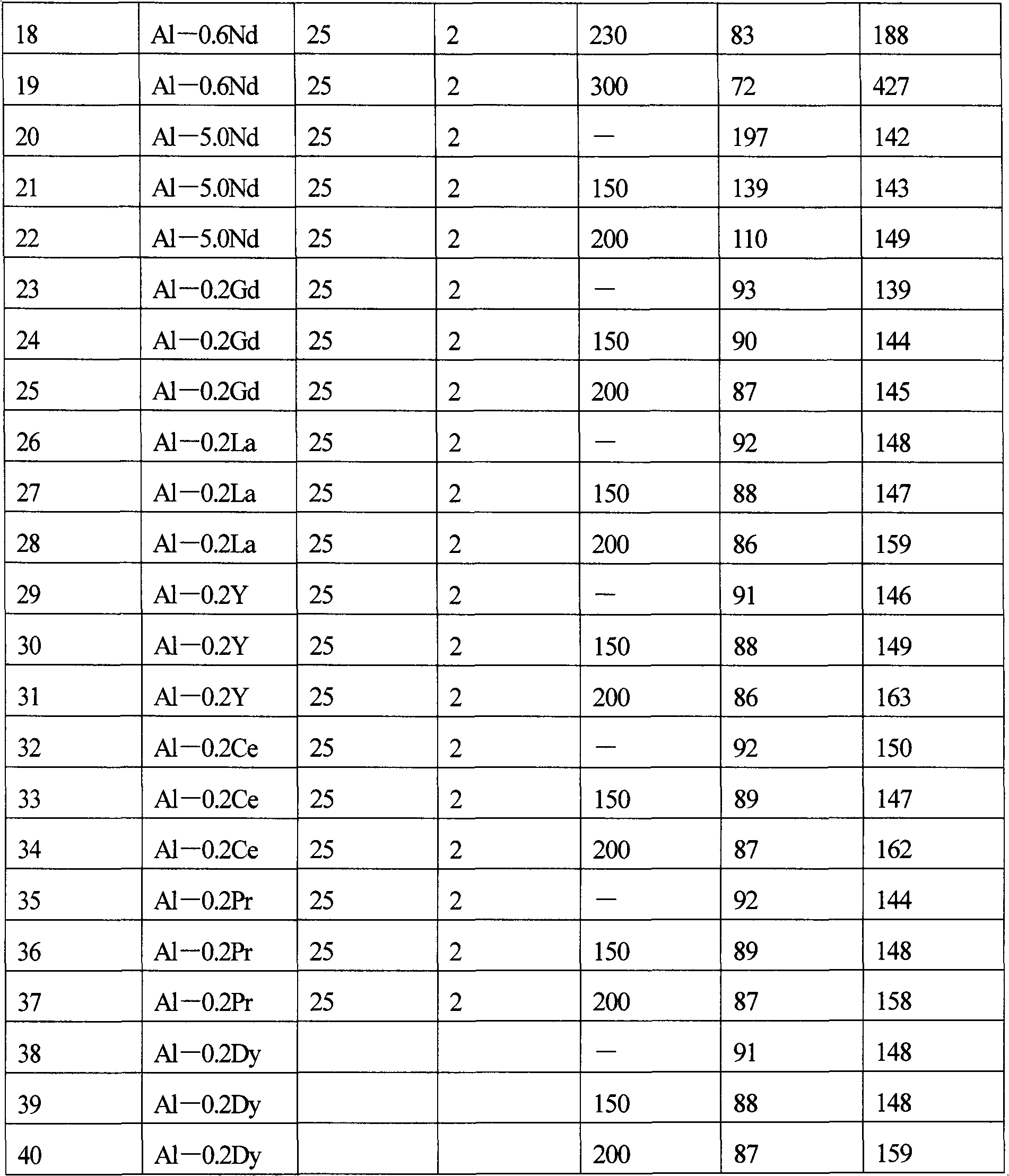

Embodiment 1

[0033] An alkali-free glass plate (thickness 0.7 mm, diameter 4 inches) is set as a substrate, and on its surface, the types and contents of the rare earth elements shown in the following Table 1 are formed by DC magnetron sputtering (the unit is atom %, balance: Al and unavoidable impurities) different Al alloy films (film thicknesses are all about 500nrn). Before film formation, the atmosphere in the chamber is temporarily set to reach the vacuum degree: 3×10 -6 After Torr, the film-forming temperature and the Ar gas pressure were varied as shown in Table 1 using a disc-shaped target with a diameter of 4 inches having the same composition as that of each Al alloy film. Other sputtering conditions are as follows. Next, the Al alloy after film formation was heat-treated for 30 minutes at various annealing temperatures described in Table 1 in a nitrogen atmosphere. In Table 1, "-" means no heating (ie, room temperature). In addition, the composition of the formed Al alloy fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com