Detection bench, detection method and detection system

A detection system and detection method technology, applied in the direction of lamp testing, testing optical performance, etc., can solve the problem of shortening the production line of light-emitting components, and achieve the effect of reducing the overall volume and quantity, and reducing the volume and length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

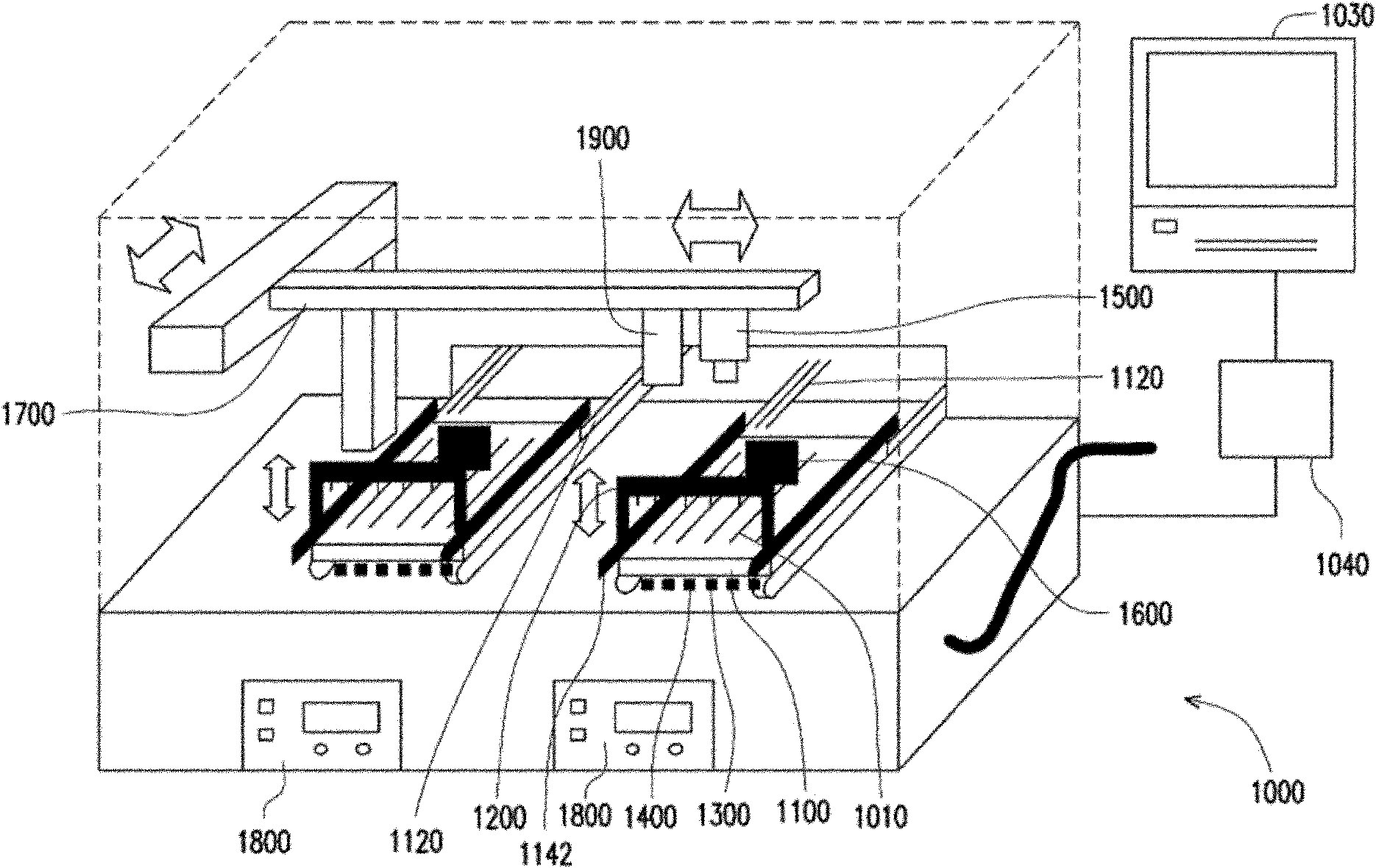

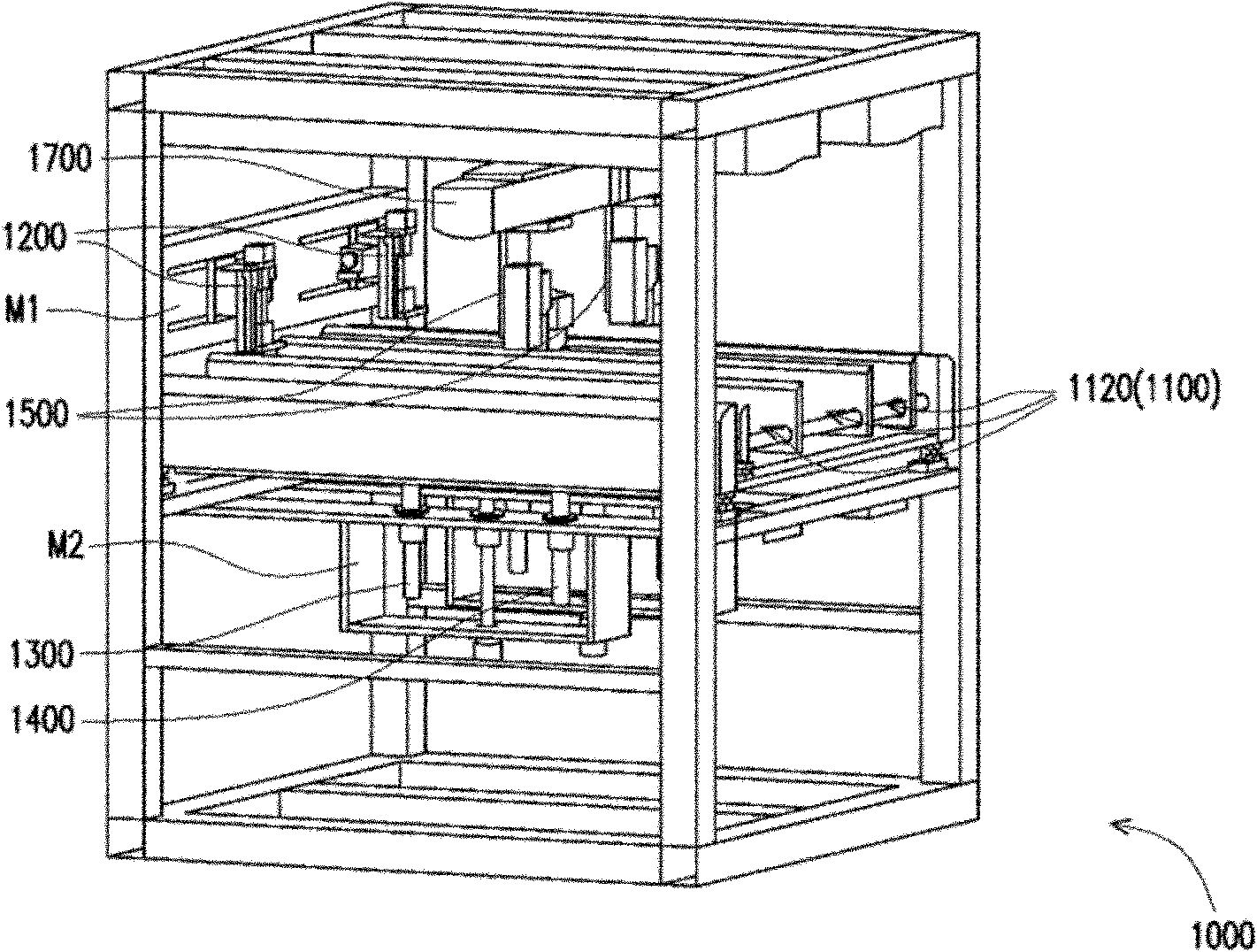

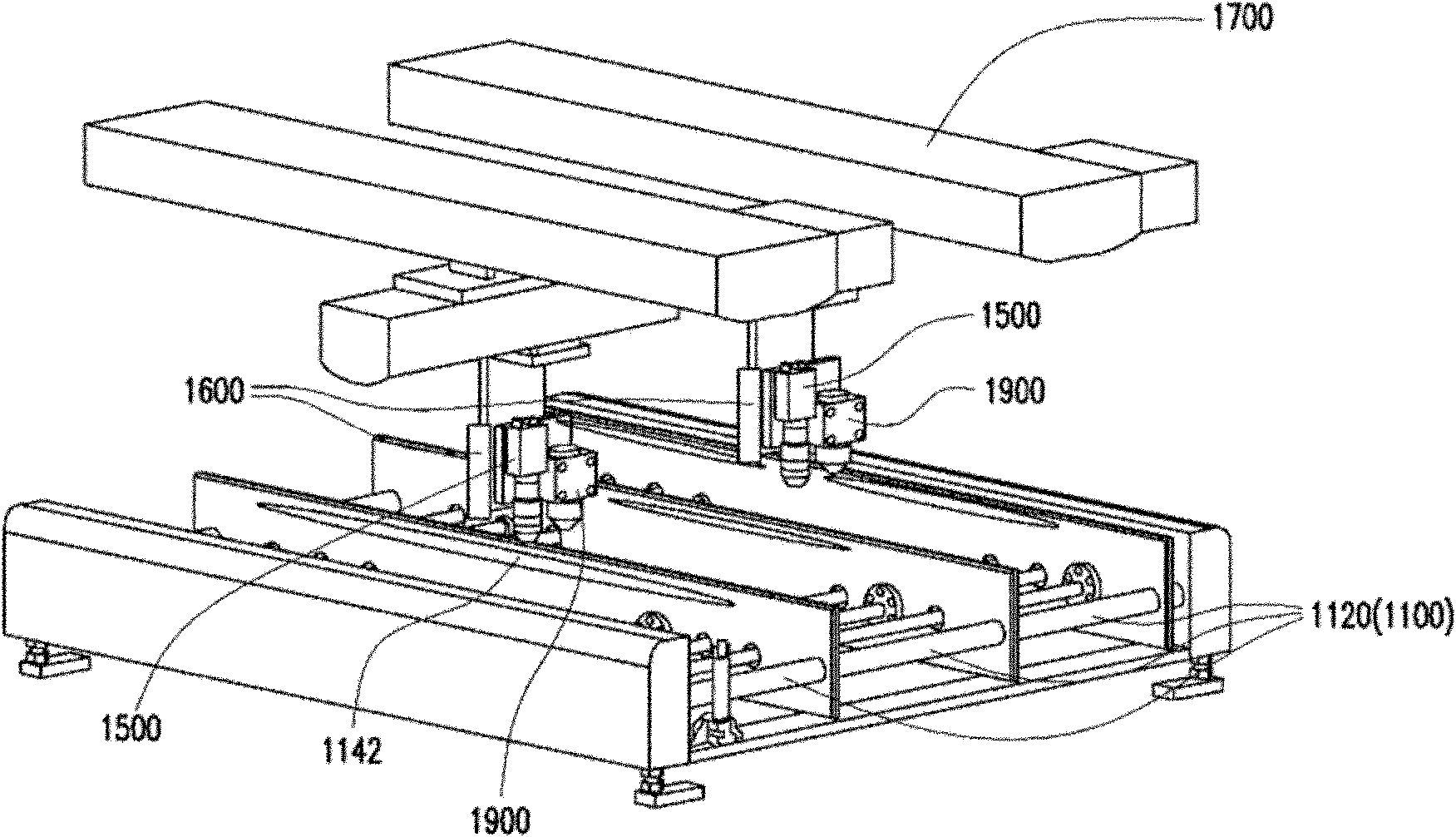

[0062] figure 1 It is a simple schematic diagram of a testing machine according to an embodiment of the present invention, figure 2 then figure 1 The partial three-dimensional schematic diagram of the specific implementation of the detection machine, and image 3 then figure 2 A partial enlarged schematic diagram of the testing machine. Please also refer to figure 1 , figure 2 and image 3 , the detection machine 1000 of this embodiment is suitable for performing optical and electrical detection on a light-emitting element 1010 . Specifically, the testing machine 1000 includes a substrate platform 1100 , a probe mechanism 1200 , a heating device 1300 , a cooling device 1400 , an image sensing device 1500 , a temperature sensing device 1600 and a moving platform 1700 . The light emitting element 1010 is disposed on the substrate platform 1100 . In this embodiment, the substrate platform 1100 is as follows figure 2 and image 3 The conveyor belt device 1120 is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com