Heat supplying method of cooling water residual heat recycling energy-saving system of thermal power plant

A waste heat recovery and energy-saving system technology, applied in hot water central heating systems, heating systems, household heating and other directions, can solve the problems of large temperature difference between high temperature water and ground temperature, affecting the efficiency of power generation, low utilization rate, etc., to achieve waste heat Effective, low heat loss, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

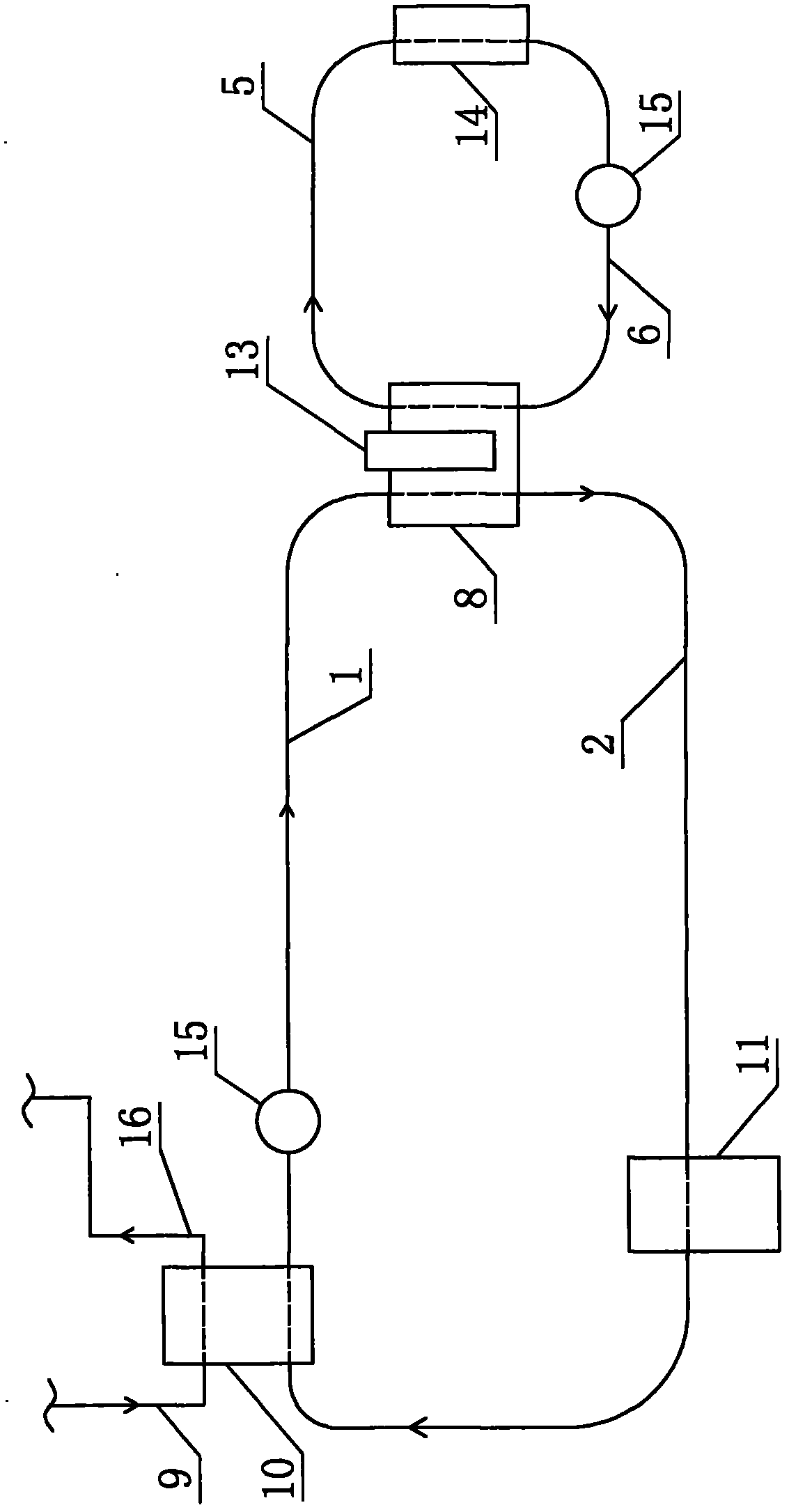

[0024] Embodiment 1: as figure 1 As shown, the heat supply method for realizing the energy saving system of cooling water waste heat recovery in a thermal power plant includes a heat exchange station E8, a condenser 10, a cooling tower 11, a user terminal 14, a water pump 15, piping systems and accessories. A heat exchange station E8 is built in the urban area. An electric-driven heat pump 13 is installed in the heat exchange station E8. Both the condenser 10 and the heat exchange station E8 are equipped with water inlet and outlet ports. The outlet pipe A1 is connected to the water inlet of the heat exchange station E8. The interface and the water outlet interface of the condenser 10, the return water pipe A2 connects the water outlet interface of the cooling tower 11, the heat exchange station E8, and the water inlet interface of the condenser 10, so that the condenser 10 and the heat exchange station in the urban area Between E8 and the cooling tower 11, the pipeline for th...

Embodiment 2

[0027] Embodiment 2: The advantage of Embodiment 1 is that the investment is low, but the cooling water circulation pipeline of the thermal power plant needs to be modified, and if a failure occurs on the way to the urban area, it will affect the cooling system of the thermal power plant. In view of this disadvantage, the second solution is designed as follows:

[0028] Such as figure 2 As shown, the heat supply method for realizing the heat recovery and energy saving system of the cooling water waste heat of the thermal power plant, the difference between the system and the embodiment 1 is that it also includes the heat exchange station D7. A heat exchange station D7 is built in the thermal power plant. A plate heat exchanger 12 is installed in the heat exchange station D7. The heat exchange station D7 is provided with an inlet and outlet water interface. Water interface, return water pipe A2 connects cooling tower 11, heat exchange station D7 and water inlet interface of c...

Embodiment 3

[0032] Embodiment 3: as image 3 As shown, the difference between it and Embodiment 2 is that multiple heat exchange stations E8 equipped with heat pumps 13 are established in parallel in urban areas, that is, heat exchange stations E8 can be established in each heating district or heating unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com