Composition of a blend of polyamide and polyester resins

A technology of polyamide resin and polyester resin, applied in the field of mixed compositions with improved compatibility, can solve the problems of unsatisfactory processing performance and properties of polymer mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

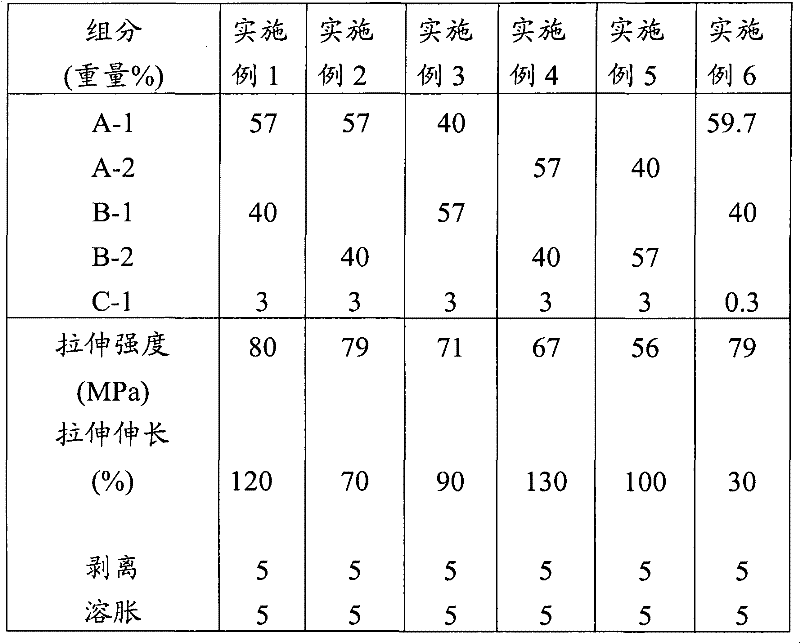

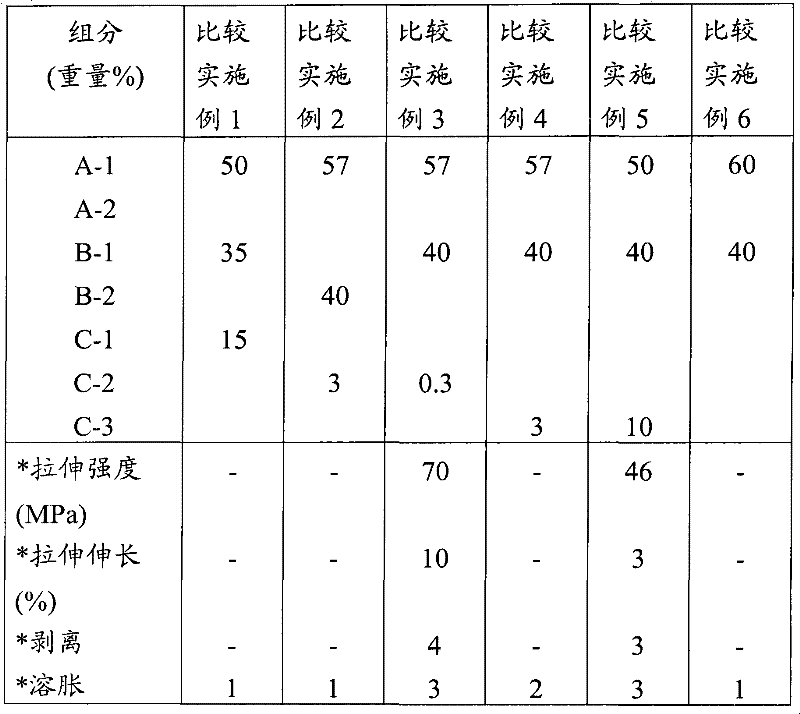

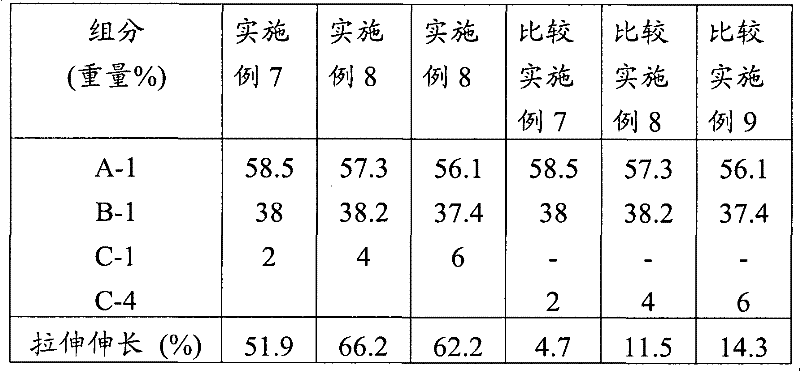

Embodiment 1 to 8 and comparative Embodiment 1 to 9

[0086] In an exemplary embodiment, the above selected components were uniformly mixed in a super mixer according to the respective mixing ratios of Examples and Comparative Examples. A twin-screw extruder (inner diameter 30mm, L / D=30) was used. Considering the melting point of the resin used, the temperature setting of the barrel inside the extruder is set to about 250°C when polyamide-6 resin is used, and the temperature setting of the barrel inside the extruder is set when polyamide-66 resin is used The temperature is about 280°C, and the gas in the screw is exhausted at a screw rotation speed of 250 to 300 rev / min and a vacuum pump pressure of 50 to 70 cm Hg. The components are thoroughly mixed in the extruder barrel and the resulting strands are rapidly cooled in a cold water bath and granulated to a defined size using a granulator.

[0087] An injection molding machine (German, ENGEL) with a closing force of 80 metric tons and an injection volume of 189.44 cc (6.4 oz) wa...

Embodiment 9 to 11

[0109] For the preparation of compositions containing recycled polyester, the protocol was the same as above. The components selected above were used according to the respective mixing ratios shown in the table below, where the properties are indicated.

[0110] Table 4

[0111] The same and satisfactory mechanical properties were observed for the various formulations of the invention.

Embodiment 12 and comparative Embodiment 12

[0113] For the preparation of the flame retardant composition, the protocol is the same as above. Components were used according to each mixing ratio of the examples and the components are shown in the table below, wherein the properties are shown in the table.

[0114] table 5

[0115]

[0116] The organophosphorus compound was Exolit OP1230 from Clariant. MPP is melamine polyphosphate.

[0117] It can thus be seen that quite pronounced flame retardant properties can be obtained for the inventive mixtures when lower amounts (30% reduction) of flame retardant are used in the formulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com