Method for accurately positioning leakage points of water supply networks

A precise positioning and leakage technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems that the leakage monitor cannot obtain the precise location of the leakage point, leakage, etc., so as to improve the efficiency of leakage monitoring and reduce the cost of pipelines. Effect of Net Leakage Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

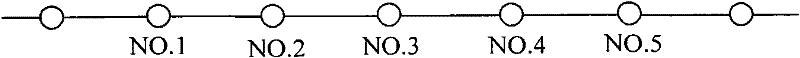

[0018] Leakage monitor layout: required for figure 2 The pipeline shown is used for leakage monitoring, and its diameter is 100mm. According to the principle of the layout of the leakage monitor, the layout distance is between 150m and 200m. The layout results are as follows: figure 2 shown.

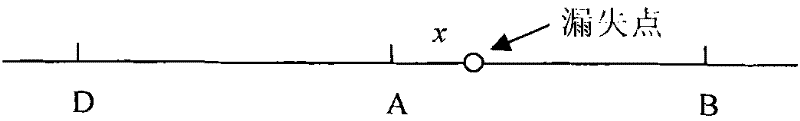

[0019] Leakage signal collection: On the 5th day after the monitoring instrument was deployed, the signal was collected, and it was found that the No. and NO.4 leakage monitor signal strengths are 15 and 13 respectively, then the NO.3 leakage monitor number is designated as A, the NO.2 leakage monitor is B, and the NO.4 leakage monitor is D .

[0020] Positioning of the leakage point: measure the distance between AB and AD to be 160m, and the distance between AD to be 170m, take the attenuation coefficient b as 25, and substitute it into the formula described in step 3 of the technical solution to obtain x=55. That is, the leakage point is located between the two monitors AB and 55 ...

Embodiment 2

[0022] Leakage monitor layout: required for figure 2 The pipeline shown is used for leakage monitoring, and its diameter is 400mm. According to the principle of layout of leakage monitors, the layout distance is between 100m and 150m. The layout results are as follows: figure 2 shown.

[0023] Leakage signal collection: On the 3rd day after the monitoring instrument was deployed, the signal was collected, and it was found that No. 4 leakage monitoring instrument issued a leakage alarm signal, which was prompted as "leakage point", and its signal strength was 30. No. 3 and NO.5 leakage monitor signal strengths are 15 and 17 respectively, then NO.4 leakage monitor number is designated as A, NO.5 leakage monitor is B, and NO.3 leakage monitor is D .

[0024] Positioning of the leakage point: measure the distance between AB and AD to be 110m, and the distance between AD to be 115m, take the attenuation coefficient b as 35, and substitute it into the formula described in step 3...

Embodiment 3

[0026] Leakage monitor layout: required for figure 2 The pipeline shown is used for leakage monitoring, and its diameter is 600mm. According to the principle of layout of leakage monitors, the layout distance is between 60m and 100m. The layout results are as follows: figure 2 shown.

[0027] Leakage signal collection: On the third day after the monitoring instrument was deployed, the signal was collected, and it was found that No. 2 leakage monitoring instrument issued a leakage alarm signal, which was prompted as "suspicious leakage point", and its signal strength was 27, and NO.1 The signal strengths of No. 1 and No. 3 leak monitors are 16 and 14 respectively, so the number of No. 2 leak monitor is A, the No. 1 leak monitor is B, and the No. 3 leak monitor is d.

[0028] Positioning of the leakage point: measure the distance between AB and AD to be 65m, and the distance between AD to be 70m, take the attenuation coefficient b as 45, and substitute it into the formula de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com