Wear resistant palm fiber

A technology of brown silk and wear-resisting ring, which is applied in the direction of heald, textile, textile and papermaking, can solve the problems of scrapping and easy wear of brown silk, and achieve the effect of improving economic efficiency, improving wear resistance and saving replacement amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

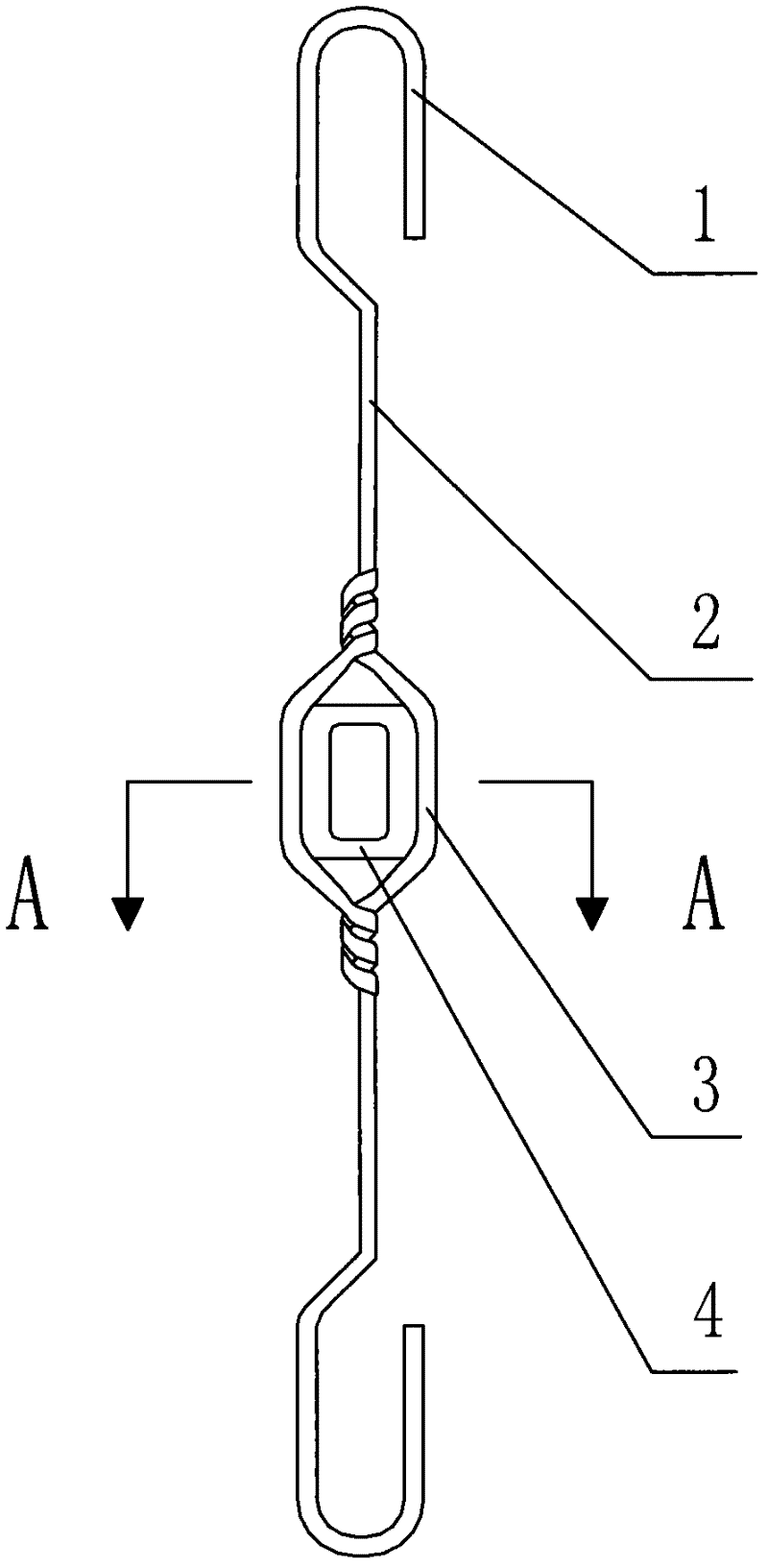

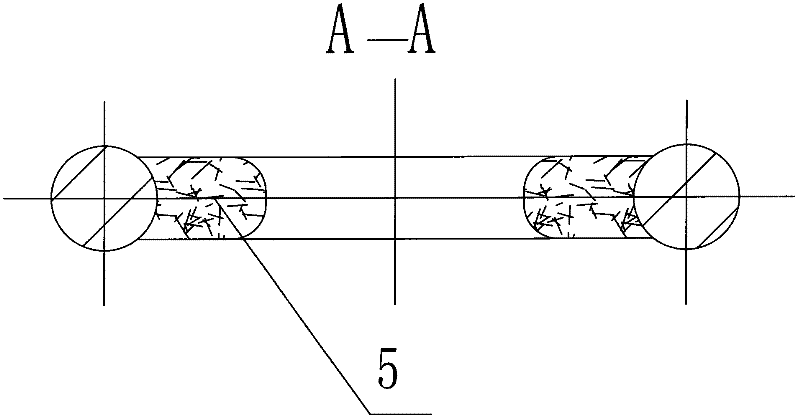

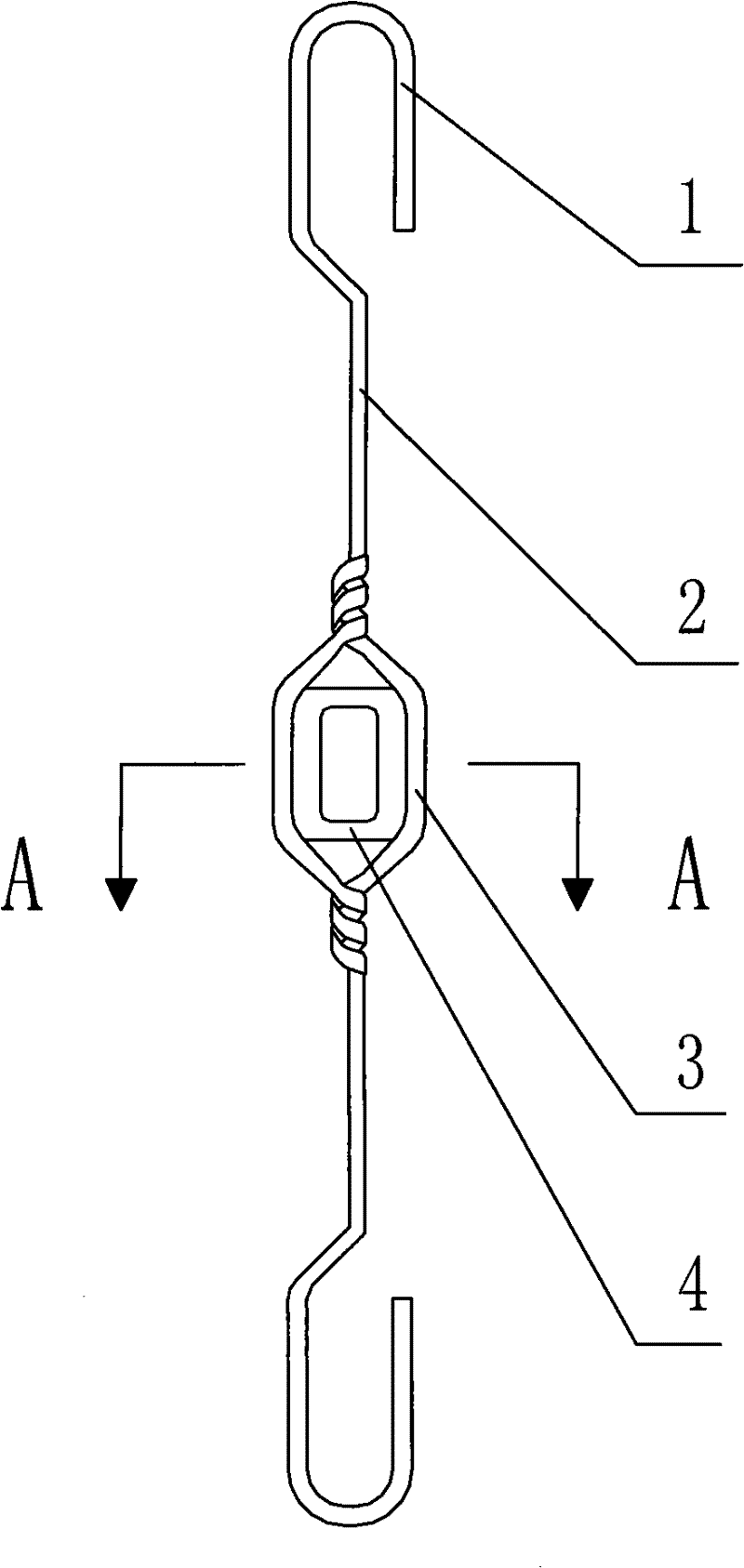

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] Such as Figure 1-2 The specific embodiment of a kind of wear-resistant brown silk of the present invention shown, a kind of wear-resistant brown silk, comprises brown silk fixed hook 1, pulling metal wire 2 and threading hole 3, is provided with wear-resistant in the threading hole 3 Grinding ring 4, the outer ring of wear ring 4 has the groove 5 that cooperates with threading hole 3 inner rings, and wear ring 4 is that manganese steel alloy material is made.

[0012] In order not to replace the whole brown wire after wearing and tearing, the threading hole 3 is made by bending the end of the spring steel wire and clamping the wear ring 4 with the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com