Coated part and manufacturing method thereof

A production method and technology for coating parts, which are applied in the field of coating parts and their production, can solve the problems of decreased anti-corrosion performance, poor wear resistance, and affect the appearance, so as to improve wear resistance and service life, and the method is simple and easy to implement. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

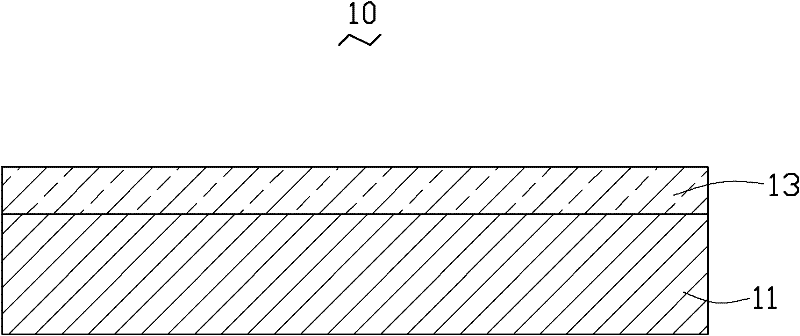

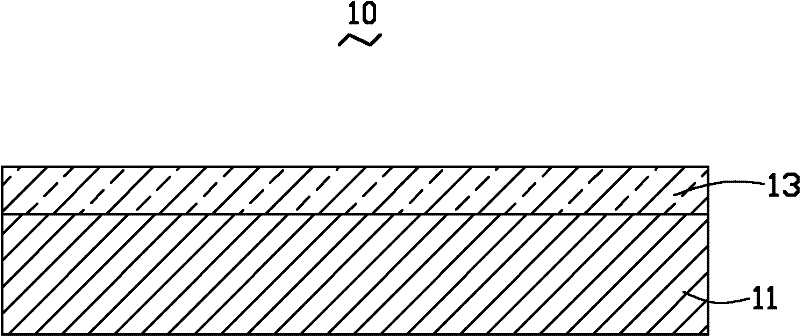

[0016] see figure 1 , a coating member 10 according to a preferred embodiment of the present invention includes a substrate 11 and an anti-fingerprint layer 13 formed on the surface of the substrate 11 .

[0017] The base body 11 can be made of metallic or non-metallic materials. The metal material may include stainless steel, aluminum, aluminum alloy, copper, copper alloy and the like. The non-metallic material is mainly plastic. The base body 11 has a rough surface, which is directly combined with the anti-fingerprint layer 13 . The roughness of the rough surface is 0.1 to 0.2 μm.

[0018] Anti-fingerprint layer 13 is a nanoscale tin dioxide (SnO 2 ) layer, which can be made by vacuum sputtering, such as magnetron sputtering. The thickness of the anti-fingerprint layer 13 is below 2 microns (μm), preferably 0.1-0.5 μm. The anti-fingerprint layer 13 is directly formed on the rough surface of the substrate 11 and has strong bonding force with the substrate 11 . The anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com