Aluminum pressing out board of unnecessary shearing process and use for method of production fish reel parts thereof

A manufacturing method and reel technology, which are applied to fishing reels, applications, fishing, etc., can solve the problem of uneven manufacturing costs of manipulator arms or resistance wheel products, difficulty in making various shapes, and increase in the number of inputs. problems, to achieve the effect of reducing the number of labor input, saving labor costs, and reducing the number of input labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The "manufacturing method of aluminum extruded square plate and reel parts for fishing rods without cutting process" of the present invention will be described in detail below in conjunction with the accompanying drawings.

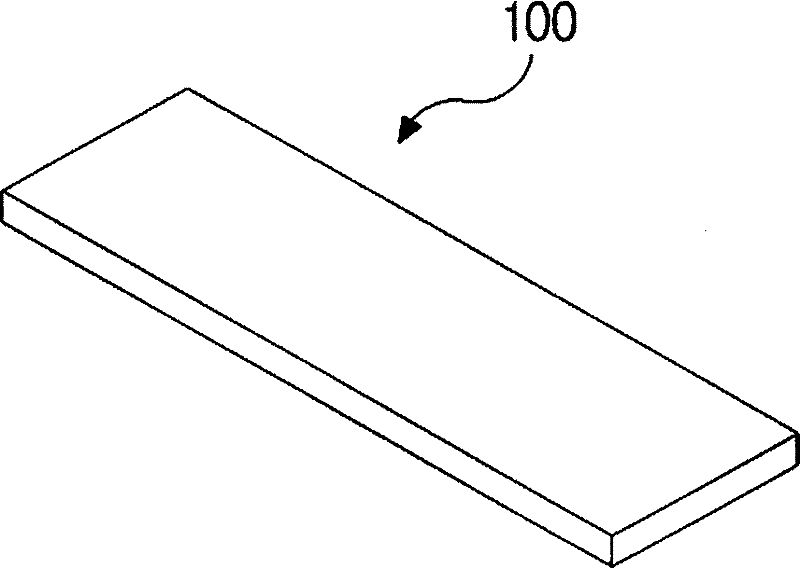

[0019] like figure 1 As shown, the aluminum extruded square plate 100 that does not require a shearing process is made of a rod-shaped aluminum raw material aluminum 7075 rod 10 (see Figure 7 ) is extruded into an extruded product in the form of a square plate (square plate) in an extrusion machine, and the aluminum extrusion processing square plate 100 has a width of 55-150mm, a length of 1000-2000mm, and a thickness of 2.5-3.9mm.

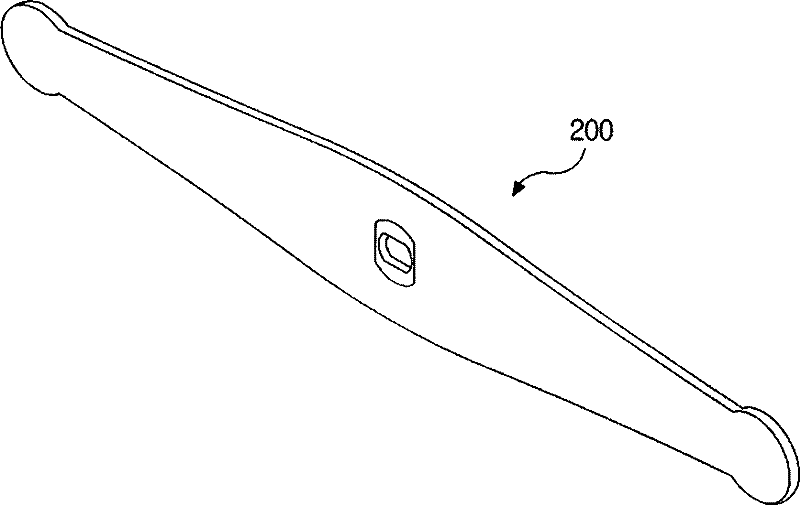

[0020] like figure 2 Shown, above-mentioned aluminum raw material aluminum 7075 bar 10 (see Figure 7 ) extruded into a square plate in an extruder, with a width of 65-150mm, a length of 1000-2000mm, and a thickness of 2.5-3.9mm in the range of the above-mentioned width 55-150mm Aluminum extrusion processing square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com