Compressor

一种压缩机、压缩空间的技术,应用在压缩机领域,能够解决不耐于旋转式压缩机横向振动、很难装配、降低润滑性能等问题,达到提高结构稳定性及装配性、生产及装配容易、减少横向振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

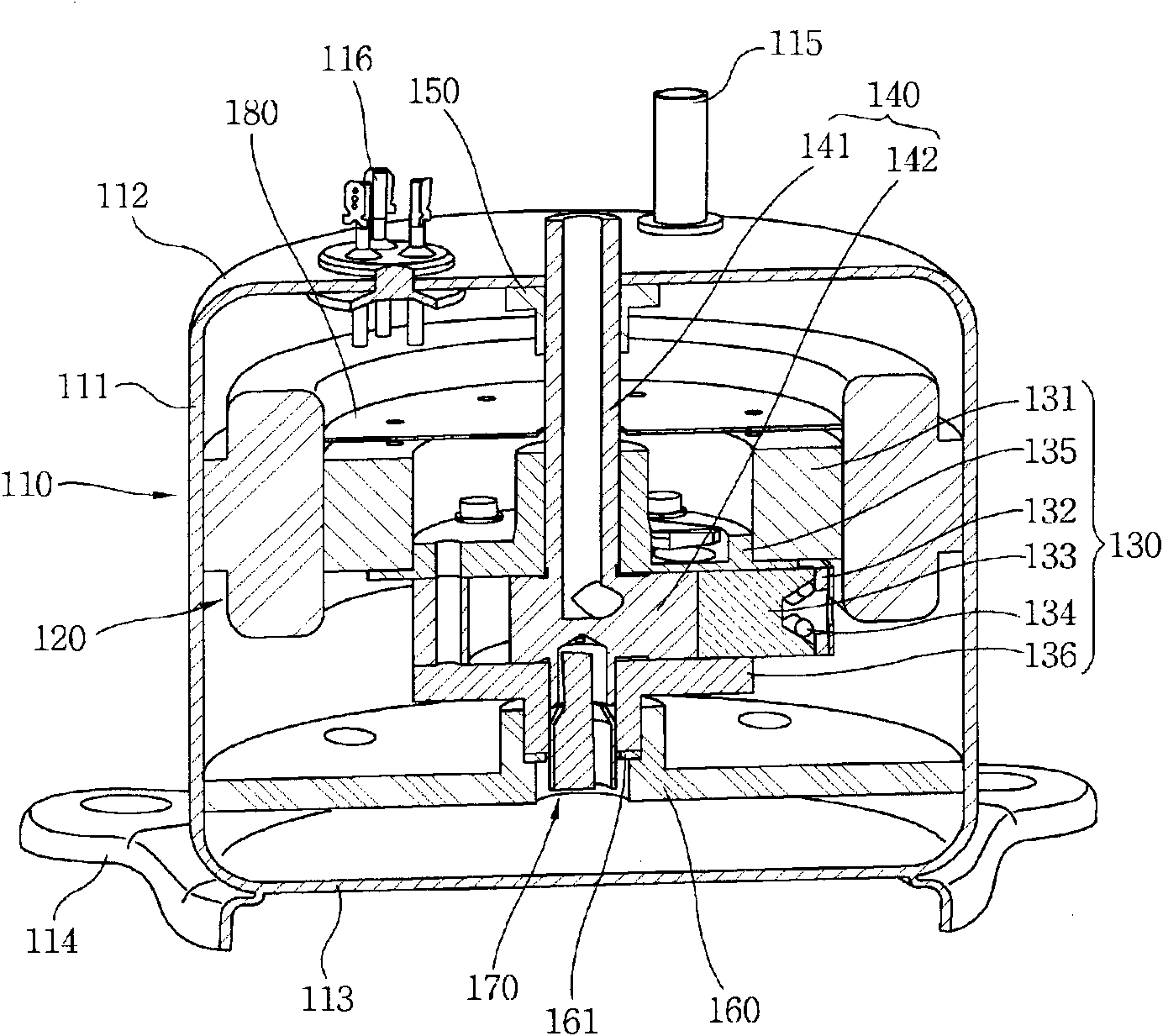

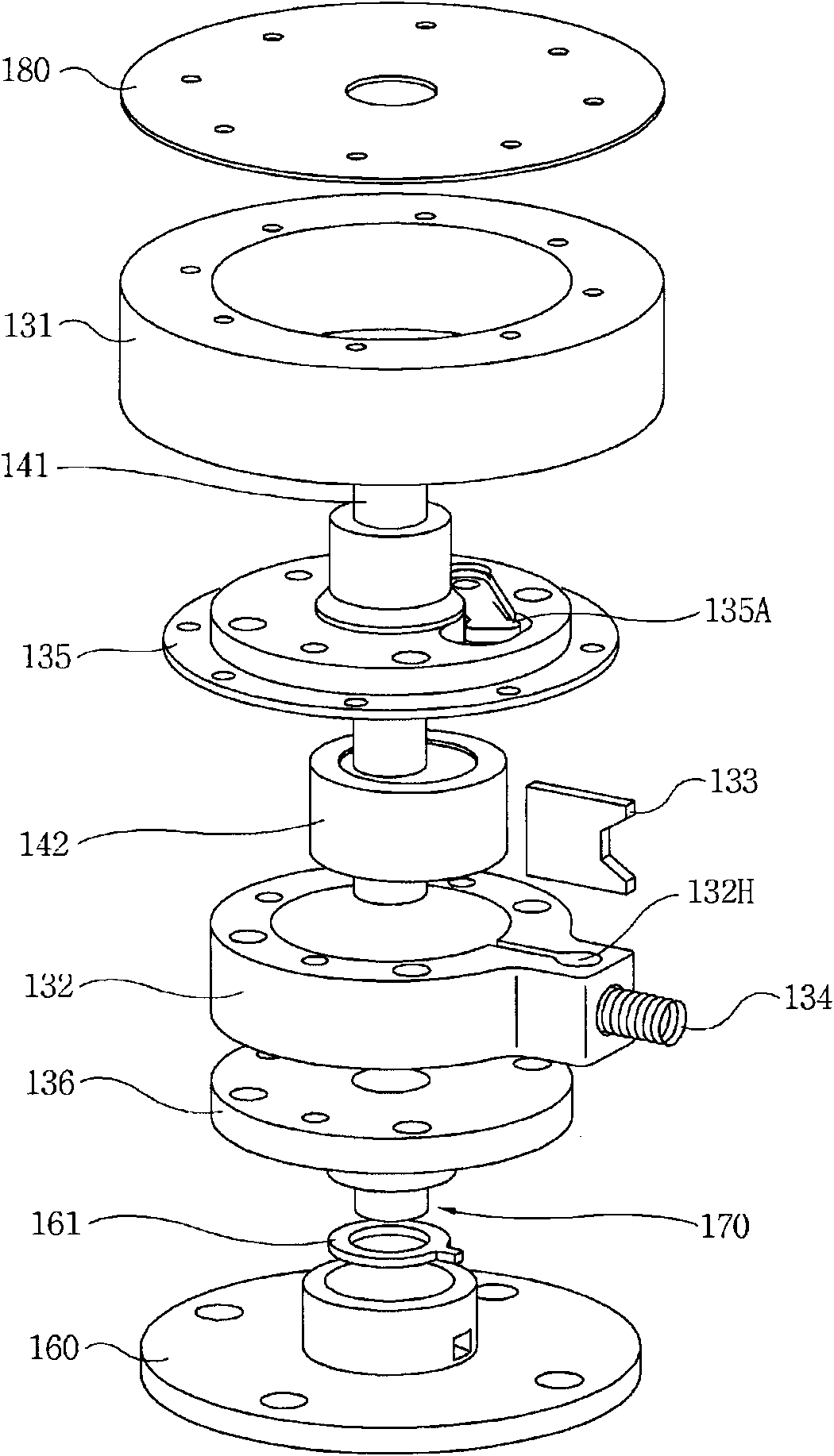

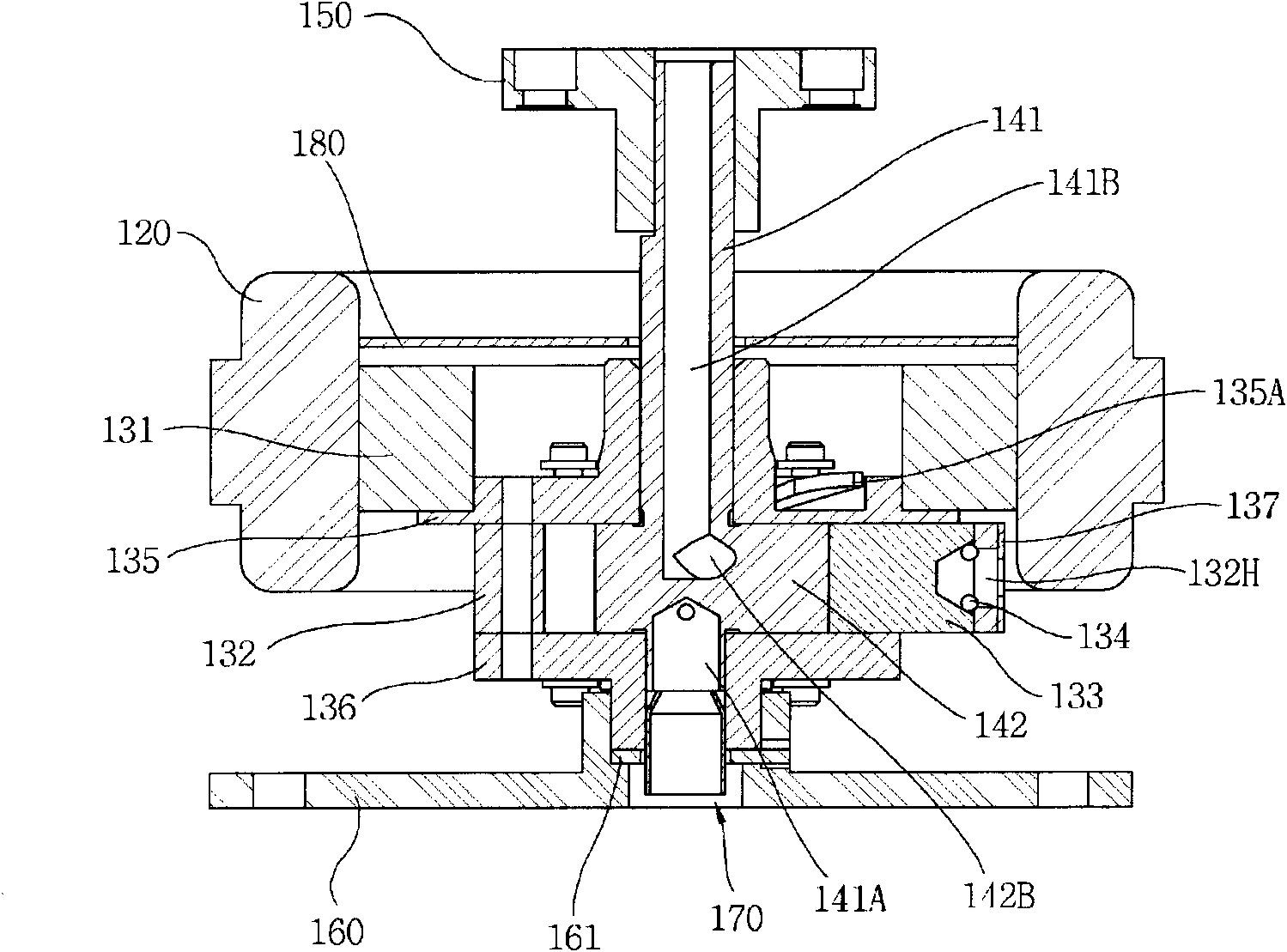

[0061] Such as Figure 1 to Figure 3 As shown, the first embodiment of the compressor according to the present invention includes: an airtight container 110; a stator 120, which is fixed in the airtight container 110; It can rotate and compress the refrigerant; the fixed part 140, which hangs the rotating part 130 on the outer peripheral surface, and at the same time, the upper and lower ends of the fixed shaft 141 are fixed to the airtight container 110 without moving; the upper shaft bracket 150, which is used When the upper end of the fixed shaft 141 is fixed on the inner side of the airtight container 110; the lower shaft bracket 160, while being separated from the lower end of the fixed shaft 141, is fixed on the inner side of the airtight container 110 so that the rotating part 130 is rotatably held by the airtight container 110. upper surface support. At this time, the motor mechanism unit that provides power by electric action includes the rotor 131 including the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com