Non-heat treated rolled steel and drawn wire rod with excellent toughness, and method for manufacturing the same

A non-heat treatment, toughness technology, applied in the field of preparing the rolled steel and the drawn steel wire rod, rolled steel and a drawn steel wire rod, can solve problems such as uneconomical, achieve excellent toughness and cold forgeability, and save the heating step Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Rolled steels were prepared from steel Nos. 1-9 described in Table 1 below under the manufacturing conditions described in Table 2 below. No. 1-3 steel, No. 8 and No. 9 steel do not satisfy the composition and composition range controlled according to the present invention. No. 4-7 steel meets the components and composition ranges controlled according to the present invention.

[0065] In addition, Table 1 shows A for each type of steel e3 (° C.), and the tensile strength and V-impact toughness of the rolled steel produced according to the preparation conditions were measured, and then shown in Table 2 below.

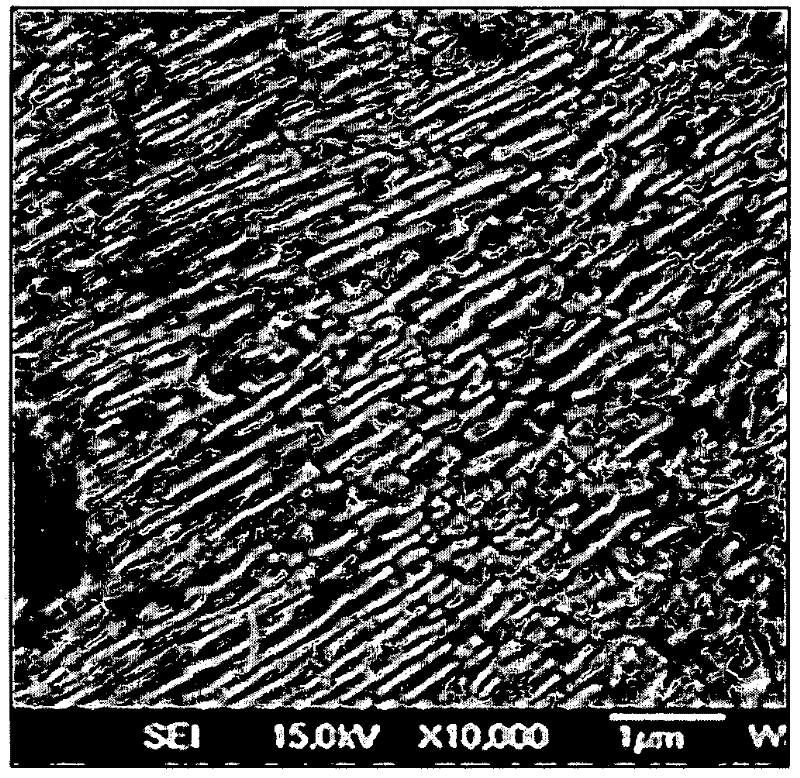

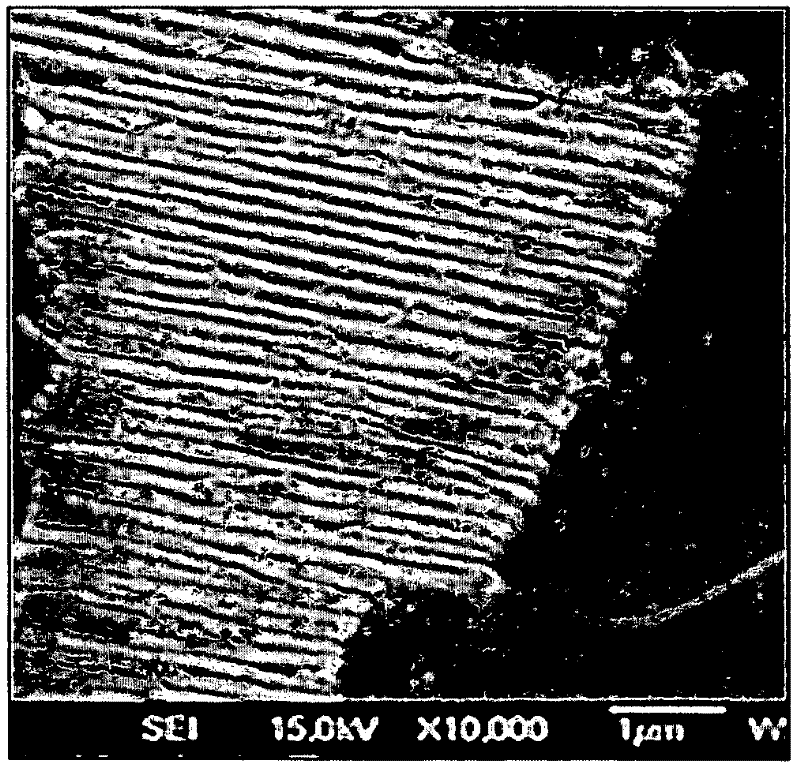

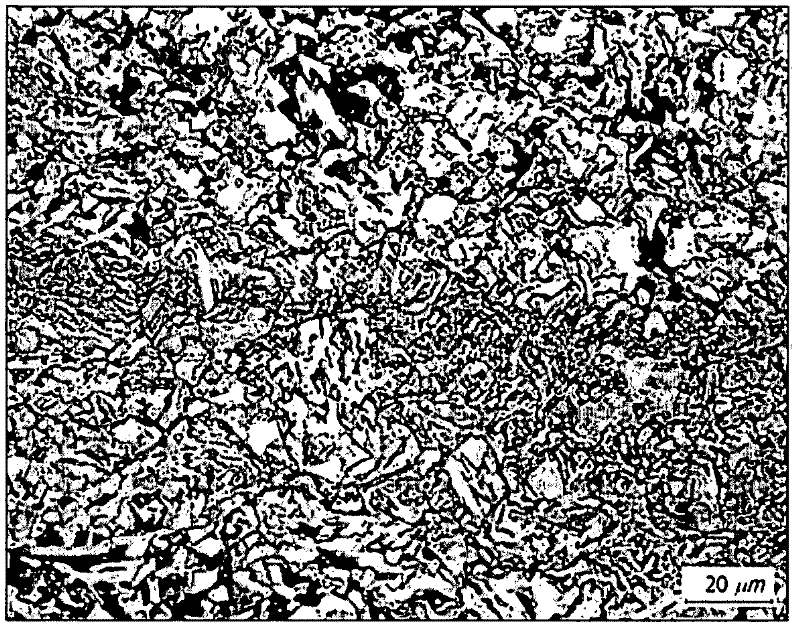

[0066] And, SEM photographs of the microstructures of Inventive Example 1, Comparative Example 1, and Comparative Example 7 are shown in the drawings.

[0067] Table 1

[0068] steel model

C (weight%)

Si(wt%)

Mn(weight%)

P (weight%)

S (weight%)

Ae 3 (℃)

No. 1 steel

0.14

0.11

1.9

0.031

0.023 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com