Decoration sheet for injection molding

A technology of injection molding and decorative sheets, which is applied in the directions of decorations, applications, household appliances, etc., can solve the problem that the chemical resistance is not fully disclosed, the mechanical strength and chemical resistance of polycarbonate materials are not suitable for application, and it cannot be said to be obtained Heat resistance, mechanical strength, chemical resistance, fluidity, etc., to achieve excellent whitening resistance, excellent chemical resistance, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

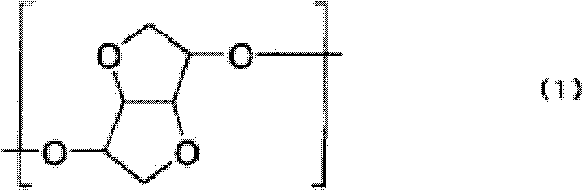

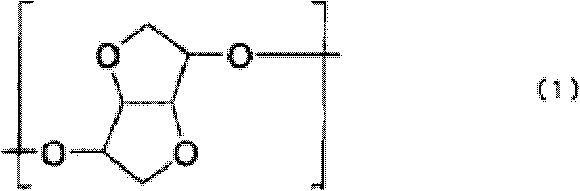

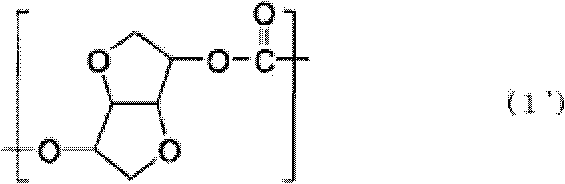

[0147] 1,608 parts by weight (11 moles) of isosorbide and 2,356 parts by weight (11 moles) of diphenyl carbonate were put into the reactor, and 1.0 parts by weight (1× 10 -4 mol) of tetramethylammonium hydroxide, and 1.1×10 -3 Parts by weight (relative to 1 mole of diphenyl carbonate is 0.25 × 10 -6 mol) of sodium hydroxide, heated to 180°C under nitrogen atmosphere and normal pressure to carry out the melting reaction.

[0148] Under stirring, slowly reduce the pressure in the reaction tank for 30 minutes, and reduce the pressure to 13.3×10 while distilling off the generated phenol. -3 MPa. After reacting in this state for 20 minutes, the temperature was raised to 200°C, and then the pressure was reduced slowly over 20 minutes, while the phenol was distilled off at 4.00×10 -3 The reaction was carried out at MPa for 20 minutes, the temperature was further raised to 220° C. for 30 minutes, and the temperature was raised to 250° C. for 30 minutes.

[0149] Next, slowly deco...

Embodiment 2

[0152] 66.42 parts by weight (0.45 moles) of isosorbide, 11.52 parts by weight (0.15 moles) of 1,3-propanediol (PD) and 129.81 parts by weight (0.61 moles) of diphenyl carbonate were put into the reactor as a polymerization Catalyst uses 1.0 parts by weight (relative to 1 mole of diphenyl carbonate is 1 * 10 -4 mol) of tetramethylammonium hydroxide, and 1.1×10 -3 Parts by weight of sodium hydroxide (relative to 1 mole of diphenyl carbonate is 0.25 × 10 -6 mol), except that, the melt polymerization of the polycarbonate resin was carried out in the same manner as in Example 1. The obtained polymer had a specific viscosity of 0.25 and a glass transition temperature of 116°C.

[0153] The obtained polycarbonate resin was carried out in the same manner as in Example 1 to obtain a base film. Table 1 shows the results of evaluating the plane orientation coefficient, total light transmittance, haze, solvent resistance, and pencil hardness of this film.

Embodiment 3

[0155] Put 731 parts by weight (5.0 moles) of isosorbide, 720 parts by weight (5.0 moles) of 1,4-cyclohexanedimethanol (CHDM) and 2142 parts by weight (10 moles) of diphenyl carbonate into the reactor 1.0 parts by weight (1×10 per mole of diphenyl carbonate) was used as a polymerization catalyst -4 mol) of tetramethylammonium hydroxide, and 1.1×10 -3 Parts by weight of sodium hydroxide (relative to 1 mole of diphenyl carbonate is 0.25 × 10 -6mol), except that, the melt polymerization of the polycarbonate resin was carried out in the same manner as in Example 1. The obtained polymer had a specific viscosity of 0.35 and a glass transition temperature of 104°C.

[0156] The obtained polycarbonate resin was carried out in the same manner as in Example 1 to obtain a base film. Table 1 shows the results of evaluating the plane orientation coefficient, total light transmittance, haze, solvent resistance, and pencil hardness of this film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hazing | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com