Miniature taking lens

A lens and miniature technology, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems of increasing the difficulty of manufacturing, aspheric lens aspheric surface turning, large fluctuations, and long overall length of the lens to achieve smooth aspheric surface Moderate, optical total length, good image quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

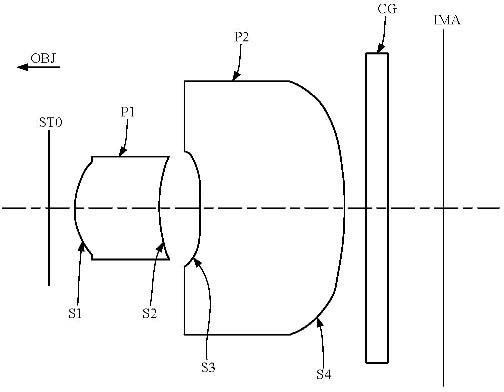

[0036] The miniature imaging lens of the present invention can be applied to portable electronic devices such as mobile phones, small digital cameras, etc., to image objects on an image sensing element such as CCD or CMOS. refer to figure 1 , the optical structure of the micro imaging lens of the present invention includes an aperture stop STO, a first lens P1 and a second lens P2 in order from the object end OBJ to the image end IMA. The main function of the first lens P1 close to the aperture stop STO is to guide imaging and provide refractive power (Refractive Power), and the main function of the second lens P2 is to correct various aberrations. This type enables the miniature imaging lens of the present invention to obtain a shorter total optical length (Total Optical Track). Specifically, the first lens P1 is a crescent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com