Icing-resistant paint and preparation method thereof, aluminium wire and preparation method thereof and transmission conductor

An anti-icing and aluminum wire technology, applied in coatings, conductors, circuits, etc., can solve the problems of reducing ice and snow protection, energy consumption, and high prices of PTC materials, and achieve the effect of good bonding force and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

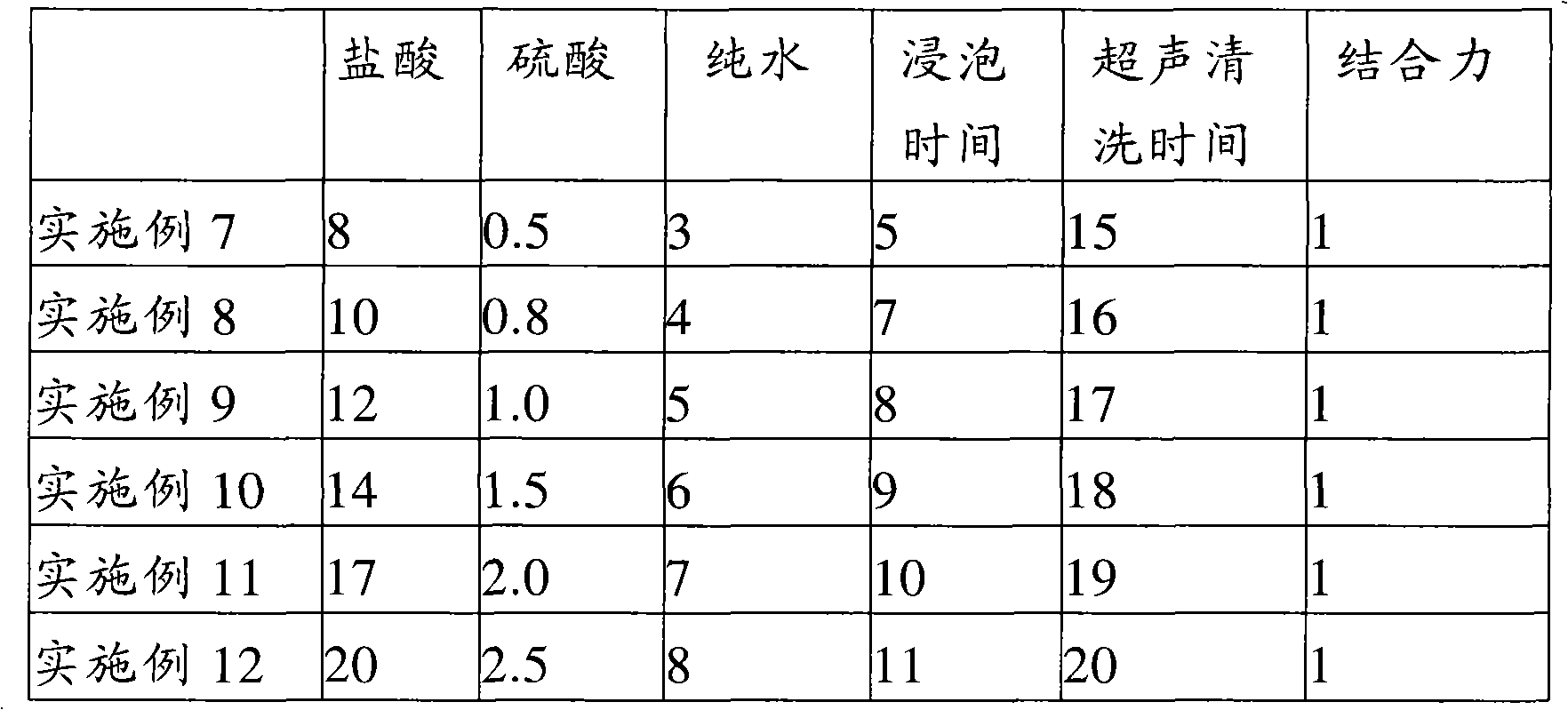

Examples

Embodiment Construction

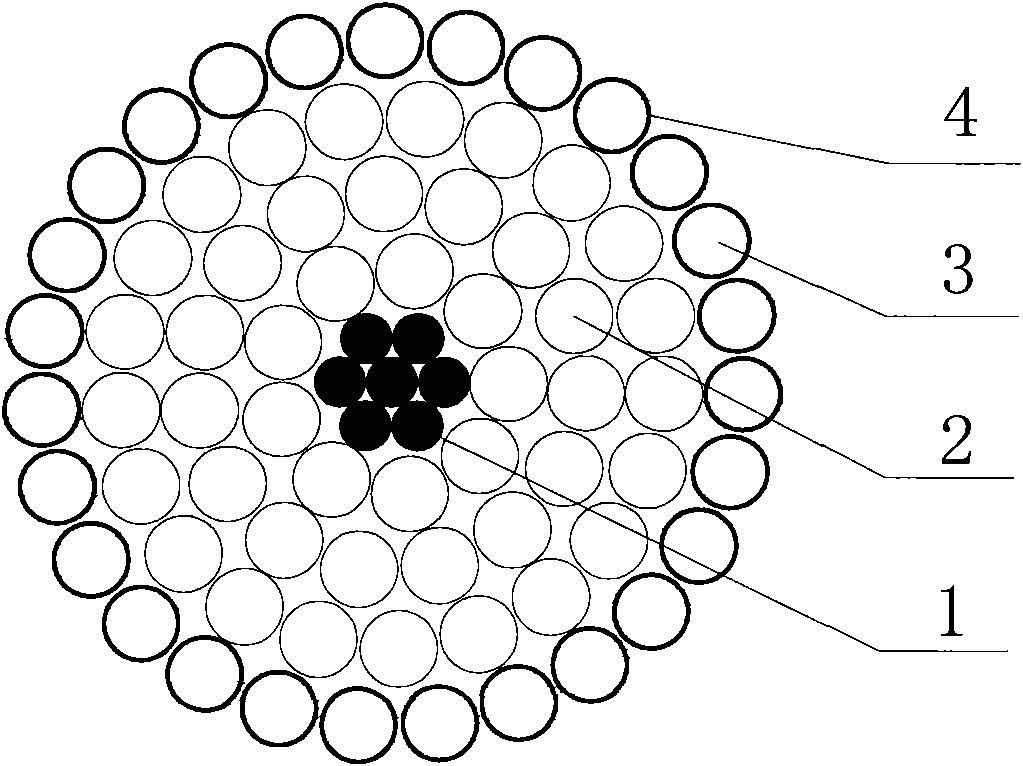

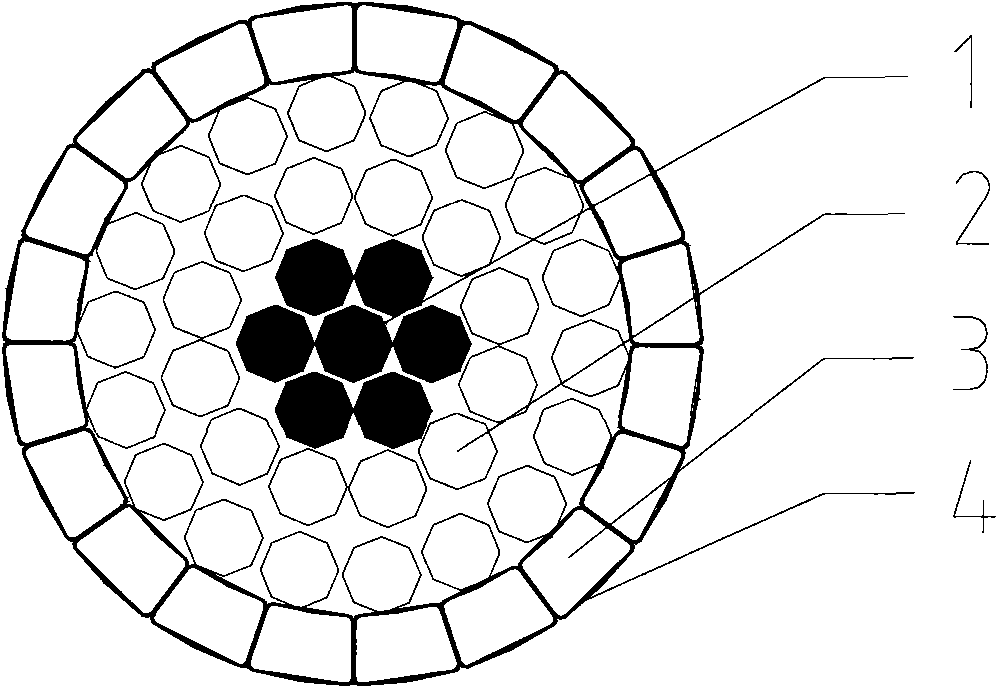

[0053] In order to enable those skilled in the art to better understand the technical solution of the present invention, the anti-icing coating and its preparation method, aluminum wire and its preparation method, and power transmission wire provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples .

[0054] The anti-icing coating of the present embodiment obtains by following method:

[0055] First, stir ethanol and n-hexane at room temperature for 15 to 20 minutes according to the volume ratio to obtain a transparent mixed solvent (or base material). The surface energy of this mixed solvent is 33.84±0.83mJ m -2 Then mixed solvent and fluorosilane are mixed by volume ratio at room temperature, so as to obtain the anti-icing coating with superhydrophobic properties (hydrophobic properties) such as larger contact angle and rolling angle, and this anti-icing coating is A clear solvent.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com