Method for preparing propylene by disproportionating fluidized bed olefin

An olefin disproportionation and fluidized bed technology, which is used in hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, catalysts for physical/chemical processes, etc. Effects of strength, high reactivity and propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

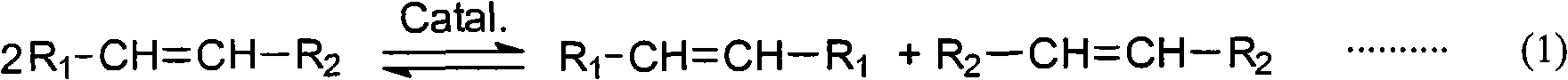

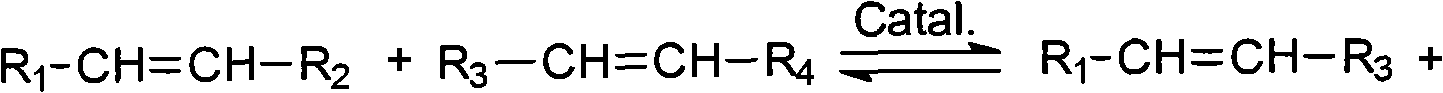

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] MCM-48 mesoporous molecular sieves were produced by conventional methods, with a pore size of 3.4 nm and a specific surface area of 1213 m 2 / gram.

[0028] Soak 1 kilogram of MCM-48 in 2 kilograms of deionized water for 10 minutes, beat for 10 minutes, add 200 grams of ammonium metatungstate solution containing 63 grams, and finally add 200 grams of silica sol (silicon oxide content 40%) and beat for 15 minutes to obtain 40% solids slurry. The slurry was spray-dried at an inlet air temperature of 600°C and an outlet air temperature of 350°C, and then baked in a muffle furnace at 550°C for 4 hours to make a catalyst. The average particle size of the catalyst was 60 microns. The bulk density and Wear index, results list 1.

[0029] Install 30 grams of catalyst in a Ф30 fluidized bed reactor to etherify C 4 For raw materials at space velocity WHSV6 hours -1 , Catalyst performance was evaluated under the conditions of 400°C and 0.5MPa, the result list 2.

Embodiment 2~6

[0031] The same preparation process as in Example 1, only changing the proportion of different components and mesoporous molecular sieves, to obtain different catalysts, the average particle size of the catalysts is 60 microns, the bulk density and wear index of the catalysts are tested, and the results are listed in Table 1.

[0032] Install 30 grams of catalyst in a Ф30 fluidized bed reactor to etherify C 4 For raw materials at space velocity WHSV6 hours -1 , Catalyst performance was evaluated under the conditions of 400°C and 0.5MPa, the result list 2.

[0033] Table 1 Physical property data of different catalysts

[0034]

[0035] Evaluation results of different catalysts in table 2

[0036] Example

Embodiment 7~11

[0038] With embodiment 1 catalyst, change the evaluation result list 3 of different process conditions

[0039] Table 3 Catalyst activity evaluation results under different process conditions

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com