Preparation method of tripolycyanamide veneer cover wood-based panel

A technology for melamine wood and wood panels, which is applied in the directions of wood impregnation, wood impregnation, wood processing appliances, etc., can solve problems such as insufficient beauty and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

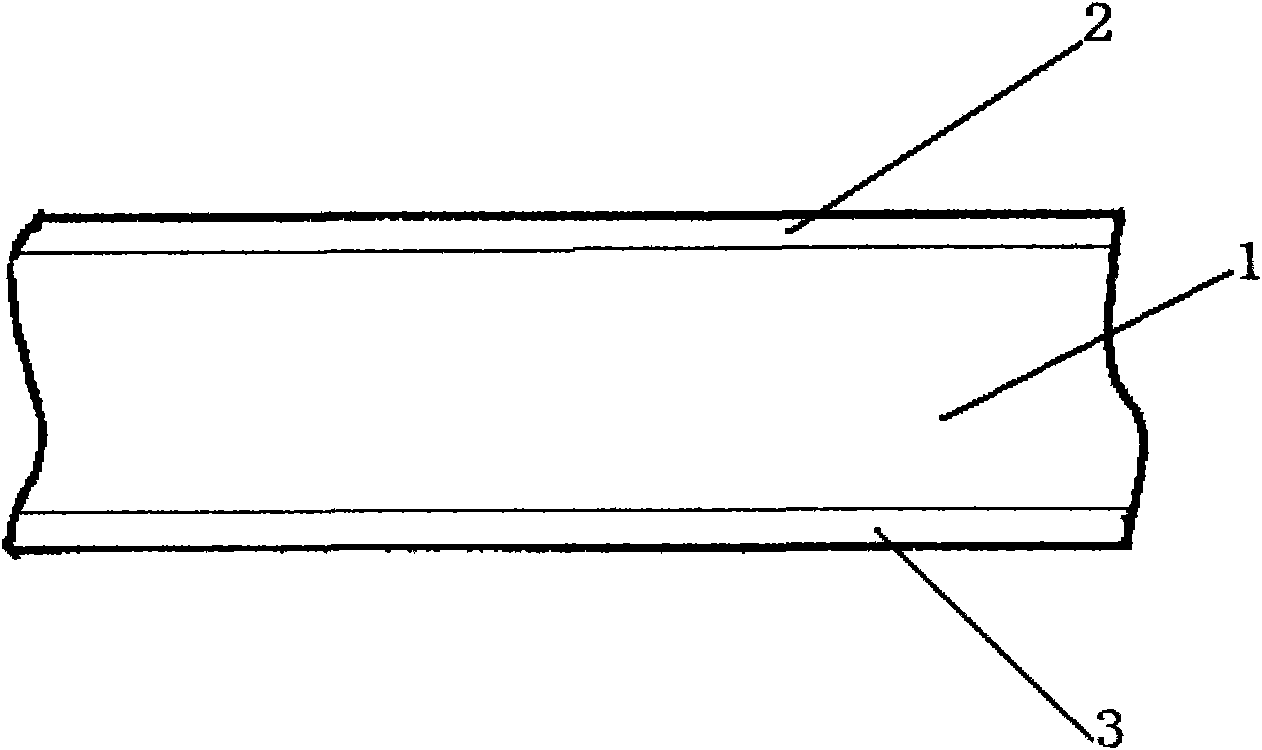

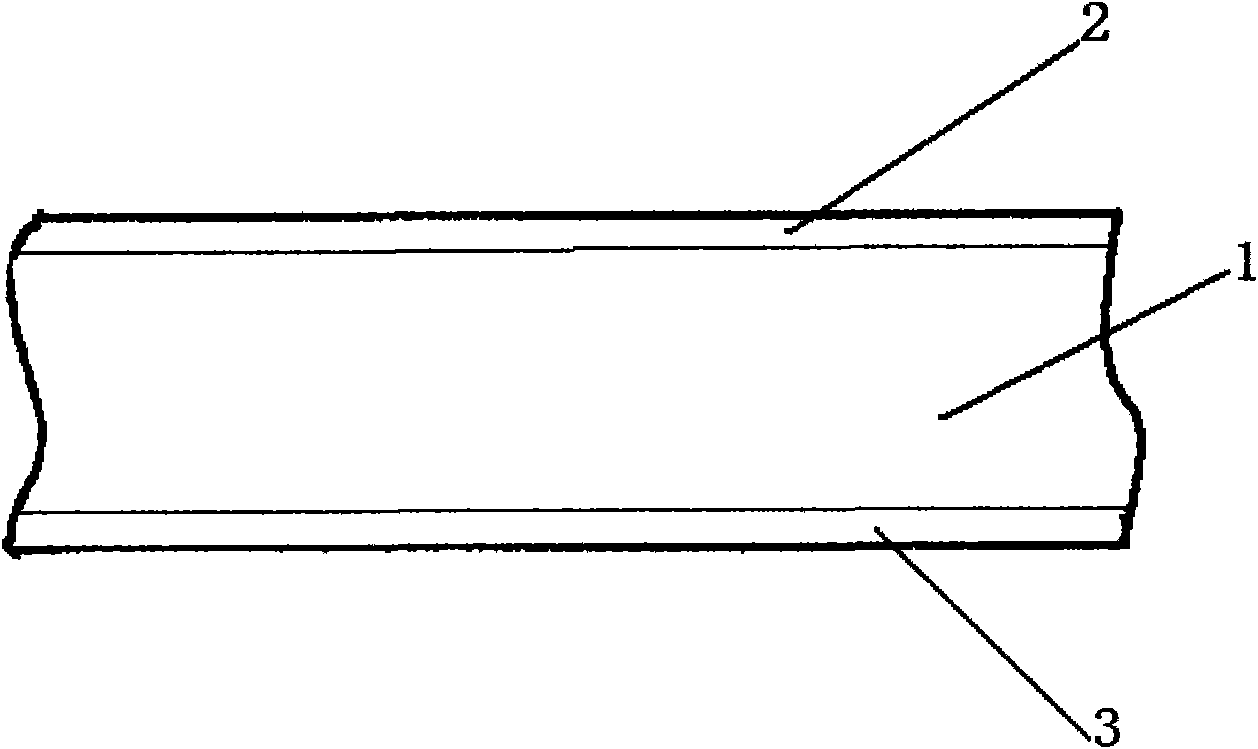

[0023] Such as figure 1 As shown, the melamine veneer paste large core board of the present embodiment comprises a large core board substrate 1, and the upper and lower surfaces of the large core board substrate 1 are symmetrically bonded with melamine veneer pastes 2, 3, and the melamine veneer Stickers 2 and 3 refer to solid wood veneers with different colors or textures impregnated with melamine. The preparation method of the large core board includes the following steps:

[0024] The solid wood veneer is impregnated into the colorless and transparent melamine resin, and the melamine glue is evenly penetrated into the solid wood veneer by impregnation;

[0025] Then dry the solid wood veneer, remove moisture and solvent volatilization, seal the solid wood veneer with a plastic film and store it in a constant temperature and humidity environment, the temperature is about 20 degrees Celsius, and the humidity is 50-60%;

[0026] Then heat and press in the hot press, the heati...

Embodiment 2

[0035] The melamine veneer laminated multilayer board of this embodiment comprises a multilayer board substrate, and the upper and lower surfaces of the multilayer board substrate are symmetrically bonded with melamine veneer, and the melamine veneer refers to a tape impregnated with melamine. There are solid wood veneers of different colors or textures, and the method for preparing the multilayer board comprises the following steps:

[0036] The solid wood veneer is impregnated into the colorless and transparent melamine resin, and the melamine glue is evenly penetrated into the solid wood veneer by impregnation;

[0037] Then the solid wood veneer is dried, and the solid wood veneer is sealed with a plastic film and stored in a constant temperature and humidity environment, the temperature is about 20 degrees Celsius, and the humidity is 50-60%;

[0038] Then use the cold-hot-cold hot pressing process in the hot press to press and bond, that is, when the slab enters the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com