A rotatable processing device

A technology of rotating processing and processing heads, which is applied in metal processing, feeding devices, metal processing equipment, etc., and can solve the problems of failing to give the trachea, winding, trachea winding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

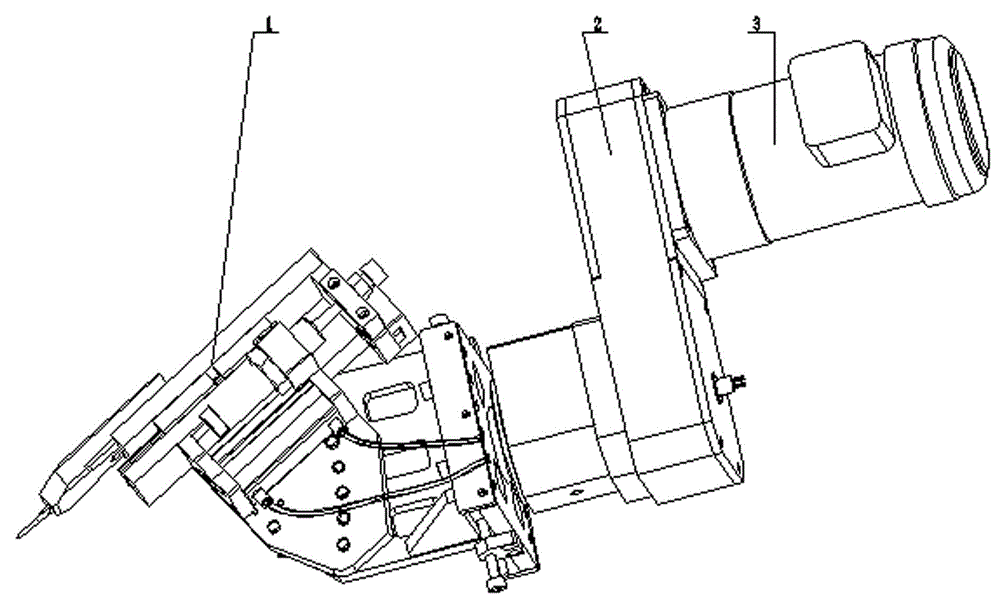

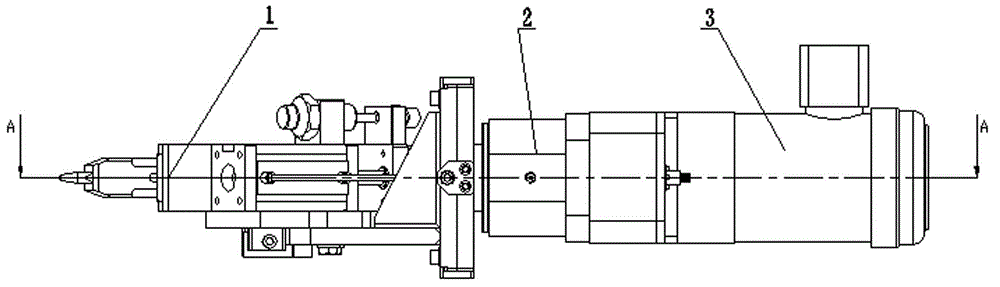

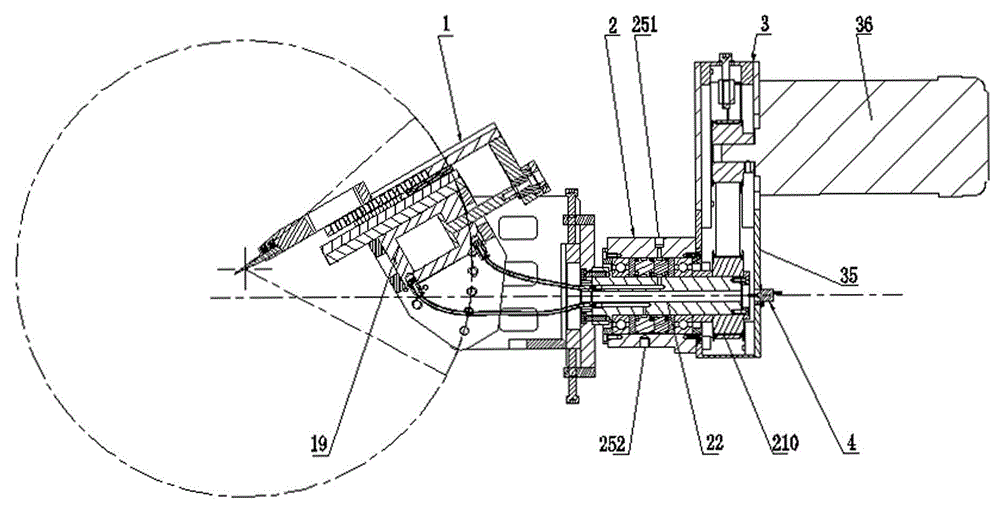

[0031] Such as figure 1 , 2 , 6, 9 (or 10), and 13, the present invention as a whole includes three parts: the processing head 1, the transmission assembly 2 and the rotary power assembly 3 connected in sequence. When the rotary power assembly 3 is working, the rotary power is transmitted to the processing head 1 through the transmission assembly 2, and the processing head 1 starts to perform rotary processing on the workpiece.

[0032] Such as Figure 3 to Figure 5 As shown, the transmission assembly 2 includes a transmission shaft 22, the processing head 1 includes a cylinder 19, and the transmission shaft 22 is provided with an air flow channel A51 and an air flow channel B52. The air cylinder 19 is connected to the airflow channel A51 and the airflow channel B52 through an air pipe A191 and an air pipe B192 respectively.

[0033] Such as Figure 5 As shown, the outer edge of the transmission shaft 22 is provided with a rotating metal sealing sleeve A28 and a rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com