Method for continuous production of tissue protein food

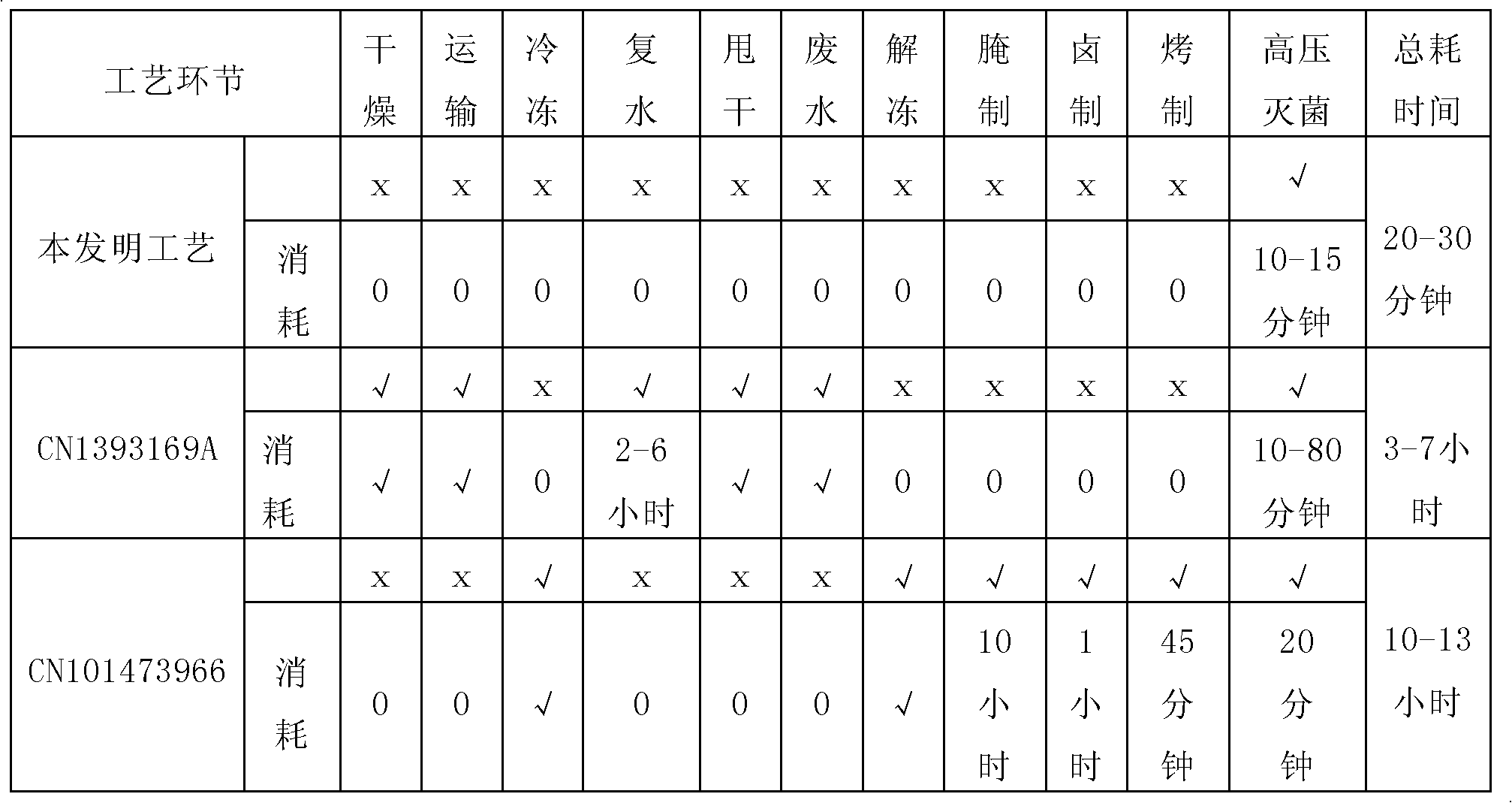

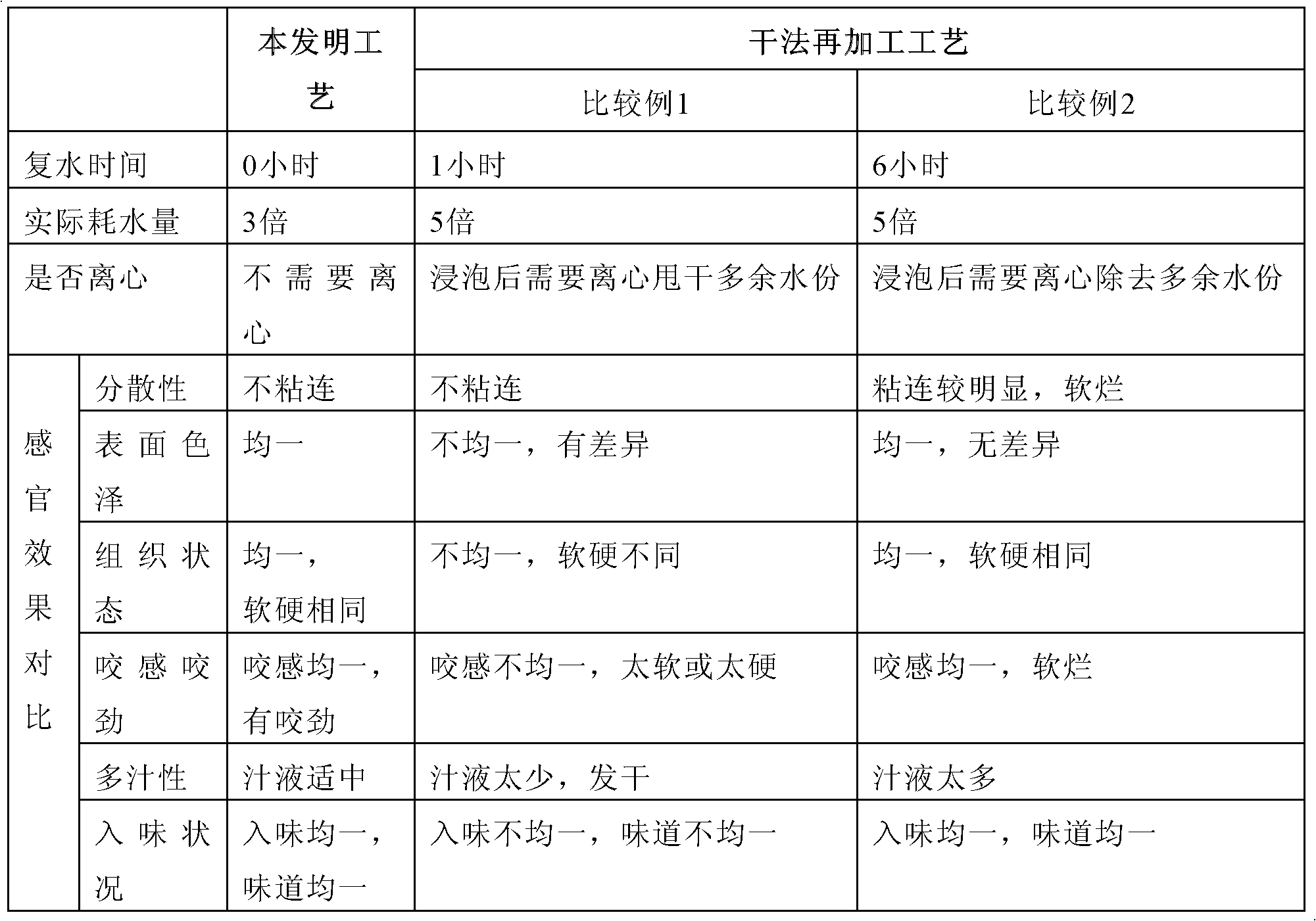

A tissue protein and food technology, applied in the field of tissue protein soft can packaging convenience food and its production process, can solve the problems of product transportation, sales in the cold chain, cumbersome processing, difficult to grasp the degree of rehydration, etc., to achieve organizational structure and good appearance, reduce the risk of microbial contamination, and realize the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

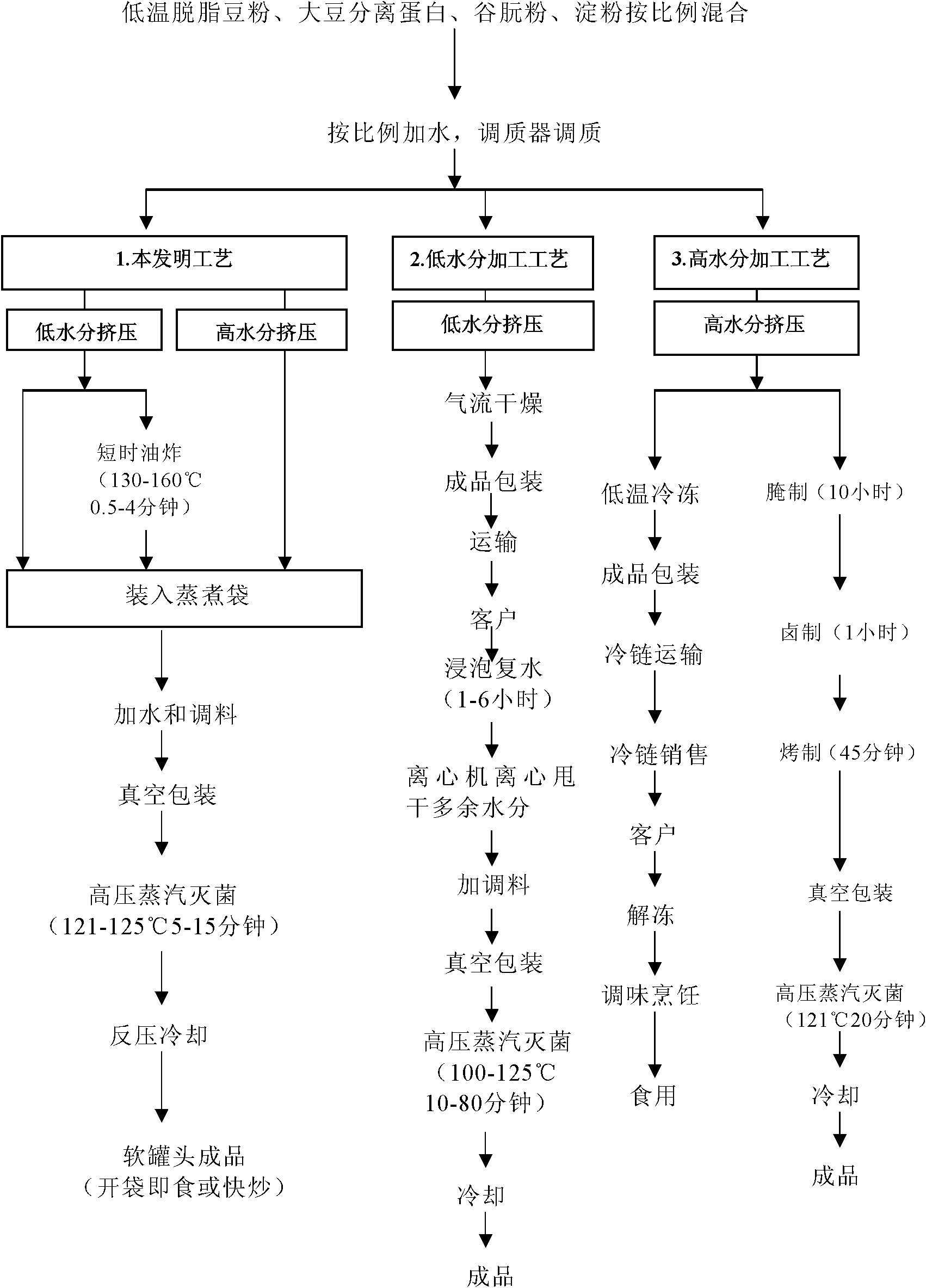

Method used

Image

Examples

Embodiment 7

[0146] Mix evenly the raw material powder containing 50 parts of low-temperature defatted soybean flour, 20 parts of soybean protein isolate, 20 parts of gluten powder and 15 parts of starch. The moisture of 55% by weight is tempered and extruded by an extruder to obtain a low-moisture textured protein wet material and a high-moisture fibrous textured protein.

[0147] Take 15 parts of tissue protein (dry weight), add 70 parts of water (total water in the final product), add seasoning: 3 parts of salt, 1 part of vinegar, 3 parts of soy sauce, 2 parts of monosodium glutamate, 1.5 parts of modified starch, 2.5 parts of sugar, 0.25 parts of protein hydrolyzate, 1 part of vegetable oil, 0.75 parts of pepper, and a small amount of beef flavor. Vacuum packing, vacuum degree 0.07MPa. The bagged product is sterilized by high-pressure steam at 125°C for 5 minutes. After the sterilization is completed, it is cooled under back pressure to obtain the finished product. Store at room temp...

Embodiment 8

[0149] The mixed raw material powder containing 80 parts of low-temperature defatted soybean flour, 10 parts of soybean protein isolate, 5 parts of gluten powder and 5 parts of starch, the low-moisture extrusion process is tempered according to the moisture content of 30% by weight, and the high-moisture extrusion process According to the moisture content of 45% by weight, it is extruded by an extruder to obtain the low-moisture wet material textured protein and the high-moisture fibrous textured protein.

[0150] Take 35 parts of tissue protein (dry basis), add 60 parts of water (total water), add seasoning: 1.0 parts of salt, 1.0 parts of vinegar, 1.0 parts of soy sauce, 0.2 parts of monosodium glutamate, 0.3 parts of modified starch, 0.3 parts of sugar, protein hydrolyzate 0.2 parts, 0.8 parts of vegetable oil, 0.20 parts of pepper, and a small amount of pork essence. Vacuum packing, vacuum degree 0.06MPa. The bagged product is sterilized by high-pressure steam at 123°C fo...

Embodiment 9

[0152] The uniformly mixed raw material powder containing 80 parts of low-temperature defatted soybean powder, 10 parts of soybean protein isolate, 5 parts of gluten powder and 5 parts of starch is tempered according to the moisture content of 30% of the weight of the raw material, and extruded by a low-moisture extrusion process , to obtain low-moisture extruded tissue protein wet material.

[0153] Take 35 parts (dry weight) of low-moisture textured protein wet material, and fry for a short time: the oil temperature is 150°C, the time is 30 seconds, and drained. Add 60 parts of water (total water in the final product), add seasoning: 1.0 part of salt, 1.0 part of vinegar, 1.0 part of soy sauce, 0.2 part of monosodium glutamate, 0.3 part of modified starch, 0.3 part of sugar, 0.2 part of protein hydrolyzate, 1.0 part of pepper, Trace amount of pork flavor. Vacuum packing, vacuum degree 0.06MPa. The bagged product is sterilized by high-pressure steam at 123°C for 10 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com