Examination apparatus for eddy current flaw detector

An eddy current flaw detection and verification device technology, applied in the direction of material magnetic variables, etc., can solve the problems of inconvenient operation, low degree of intelligence, low verification efficiency, etc., and achieve the effect of simple operation, high degree of intelligence, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

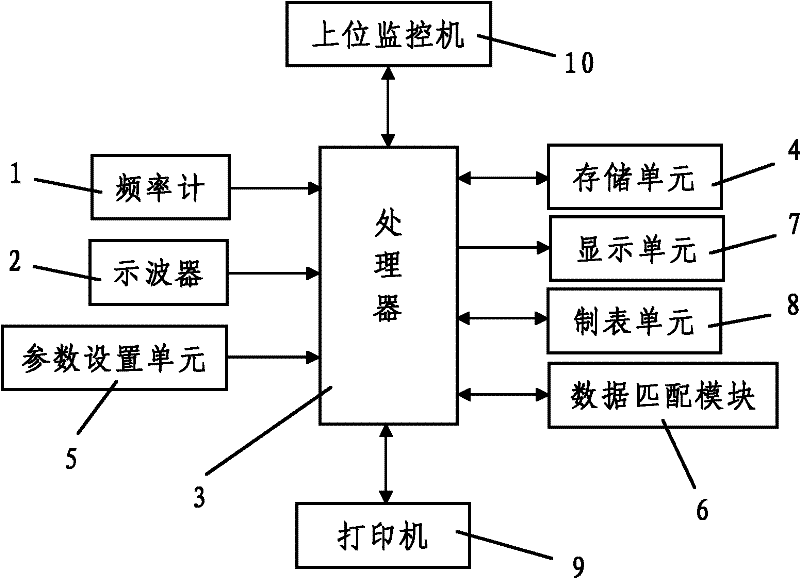

[0039] Such as figure 1 As shown, the present invention includes a frequency meter 1 and an oscilloscope 2 for synchronously testing the output frequency and output voltage of the tested eddy current flaw detector during the process of testing the standard calibration block by the tested eddy current flaw detector. The frequency meter 1 and the oscilloscope 2 are connected to the output terminal of the eddy current flaw detector under inspection. At the same time, the present invention also includes a storage unit 4, a parameter setting unit 5, a storage unit 4, a parameter setting unit 5, a storage unit 4, a parameter setting unit 5, a storage unit 4, a parameter setting unit 5 that stores standard detection data of various standard check blocks, and a standard check block input by the parameter setting unit 5. The data matching module 6 that matches the model with the standard detection database, analyzes and processes the test data of the frequency meter 1 and the oscilloscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com