Manufacturing method and structure of post-poured strip of underground building

The technology of an underground building and its manufacturing method is applied in the field of building post-casting belts, which can solve the problems of post-casting belts that cannot meet the needs of use, weak waterproof ability, and water leakage, so as to improve the performance of water leakage and water seepage prevention, Enhanced waterproof ability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

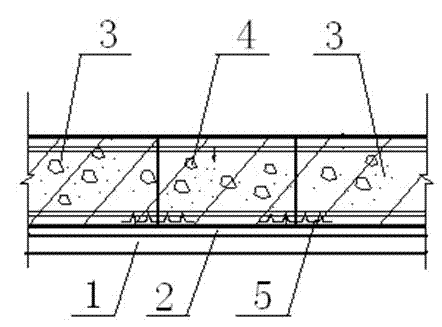

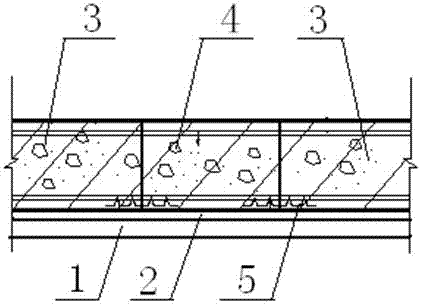

[0018] Embodiments of the present invention: when carrying out basement base plate and side wall construction of underground building, adopt the present invention to make its post-pouring tape, post-pouring tape structure of the present invention is as follows figure 1 As shown, during production, the pit floor cushion 1 of the basement is produced according to the existing method, and after the construction of the pit floor cushion 1 of the basement is completed, a layer of waterproof coiled material is fully spread on the pit floor cushion 1 2. The waterproof membrane 2 can directly use the finished synthetic polymer (polyvinyl chloride) waterproof membrane sold in the existing market, and the thickness of the finished synthetic polymer (polyvinyl chloride) waterproof membrane 2 is ≥1.2mm, Its tensile strength is 2.0-4.5MPa, its elongation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com