Method for lightening residual oil

A lightening and residual oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of increasing the impurity content of catalytic cracking raw materials, increasing the load of atmospheric distillation units, and reducing the quality of catalytic products. , to achieve the effect of reducing the generation of dry gas and coke, reducing the severity of operation, and improving mass and heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

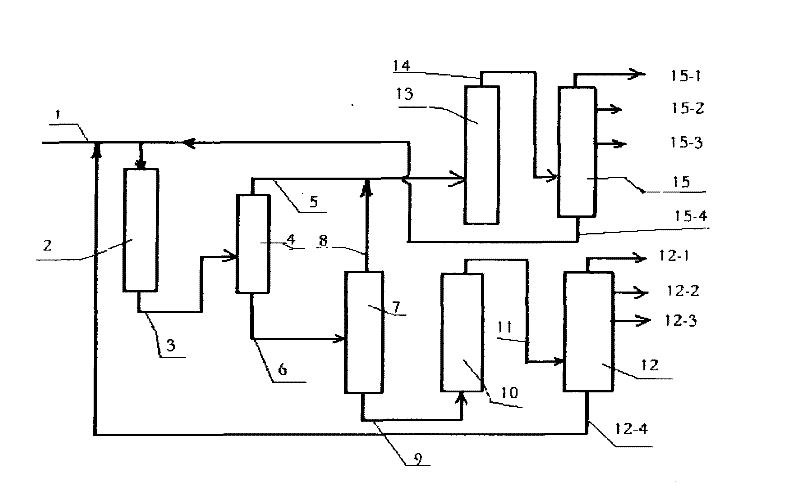

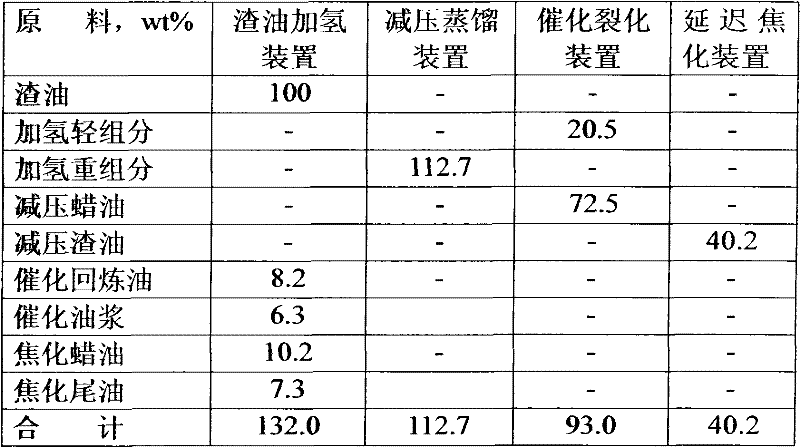

[0035] The embodiment adopts the combined method of residual oil hydrotreating, catalytic cracking, delayed coking and vacuum distillation provided by the present invention, and the flow chart is shown in figure 1 . The hydrogenated oil flashes off light components and heavy components, and its cut point is 350°C. Table 2, Table 3, Table 4, Table 5, Table 6, and Table 7 respectively show the feed properties, process conditions, feed composition of each device, product distribution and main product properties of each device.

[0036] The results show that mixing the light components produced by hydrogenation of residual oil and the wax oil obtained by vacuum distillation as raw materials for catalytic cracking greatly improves the properties of raw materials and correspondingly improves the quality of catalytic cracking products. At the same time, the yield of light oil is greatly increased ; Part of the delayed coking feed is hydrogenated residual oil, so the product quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com