Catalyst system for preparing broad-peak/dimodal polyethylene in single reactor

A bimodal polyethylene and catalyst technology, applied in the field of catalyst systems, can solve the problems of narrow molecular weight distribution, low melt flow ratio, difficult polymer handling, etc., and achieve the effects of wide molecular weight distribution, low production cost, and convenient molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

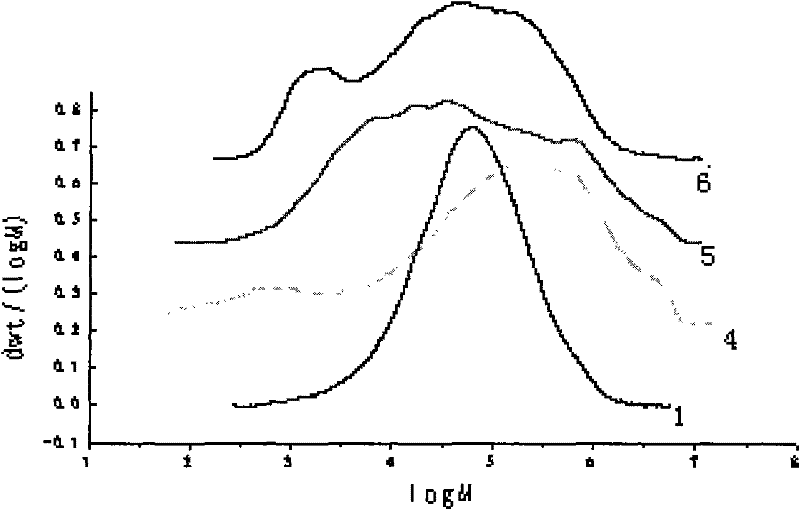

Image

Examples

preparation example Construction

[0073] ②. Preparation of host catalyst

[0074] Get component a{2-[1-(2,6-diisopropylphenylimine)methyl]pyridine}zirconium chloride in 30mLCH 2 Cl 2 Stir to dissolve at medium temperature, add component bTiCl dropwise 4 (5 mmol), the solution turned yellow and accompanied by some yellow precipitates, heated to 50-60 °C and stirred for 1 h to fully react, then dried under reduced pressure, and then washed and dried with 10 mL of diethyl ether. The product is a yellow solid powder.

[0075] ③. Load the main catalyst on the carrier

[0076] Add the main catalyst solution prepared in step ② into the carrier dispersion treated in step ①, and after reflux reaction for 2 to 3 hours, wash with hexane for 3 to 4 times. 2 drying under protection to obtain the polyethylene catalyst main component of the catalyst used for preparing broad / bimodal polyethylene in a single reactor of the present invention.

[0077] The present invention adopts the polymerization reaction method of above...

Embodiment 1

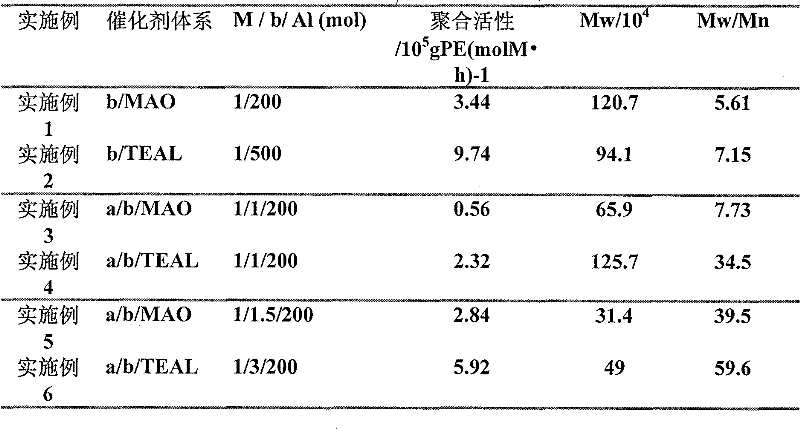

[0080] The result of ethylene polymerization using component b as catalyst and adding MAO as co-catalyst.

Embodiment 2

[0082] The result of ethylene polymerization using component b as catalyst and adding TEAL as cocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com