Battery separator

A carrier resin, fiber sheet technology, applied in the field of porous pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

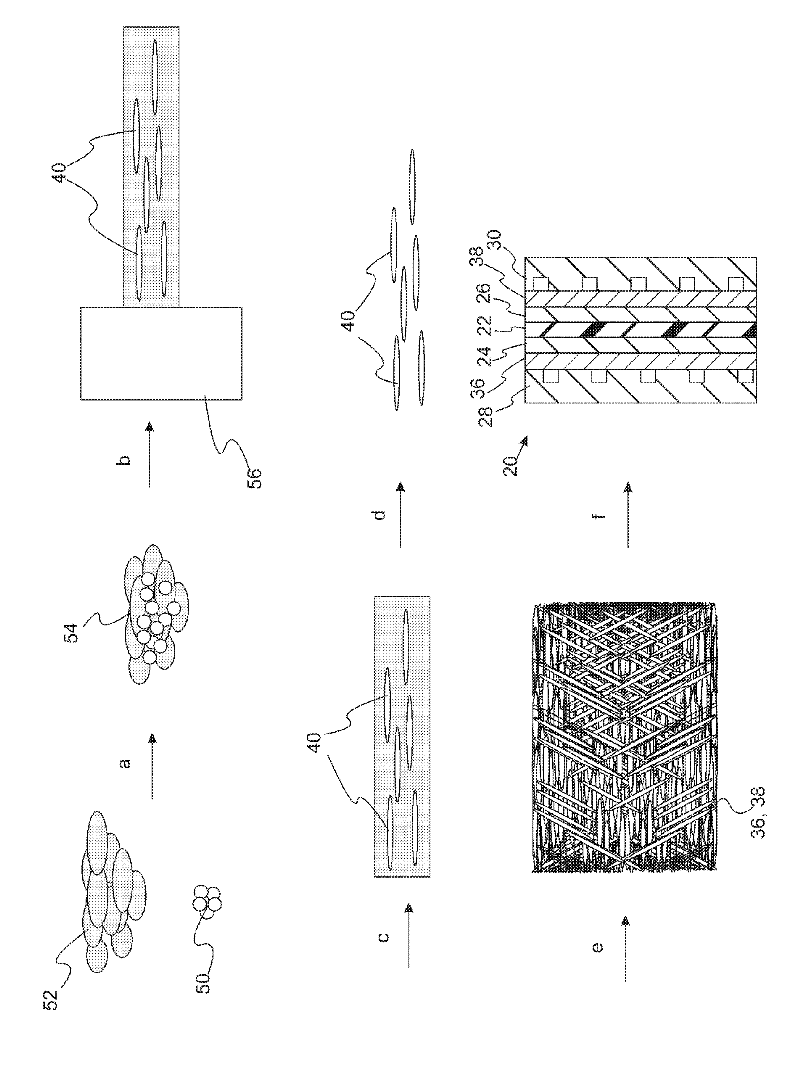

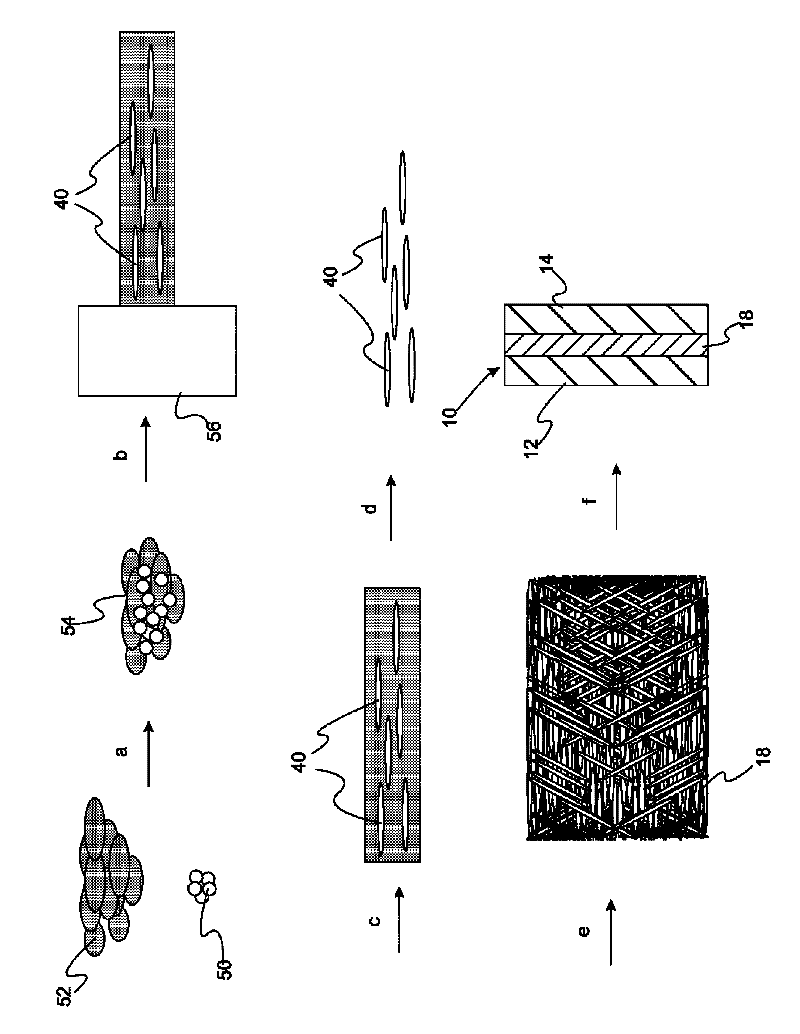

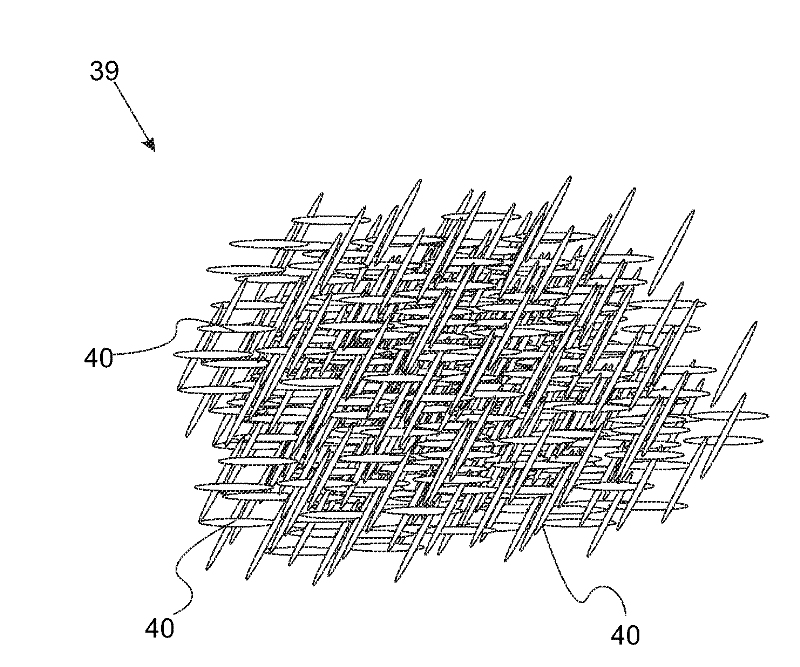

[0069] Example 1: Extruded micro and nanofibers of low molecular weight polyethylene.

[0070] Polyethylene powder (7,700Mn, 35,000Mw, Aldrich catalog number 47799-1KG, 1 g) was mixed with poly(2-ethyl-2- Oxazoline) (50,000 Mw, Aldrich 372846-500G, 9 grams) was blended in a Waring blender. The powder was brushed into the hopper of a laboratory mixing extruder (Dynisco, LME) operating at a head and rotor set temperature of 140°C, with the drive motor operating at 50% capacity. The extrudate was drawn at 1 ft / sec and wound onto a Dynisco Take-Up System (TUS). The resulting extruded strands ( Figure 4A ) suspended in three glasses of water. poly(2-ethyl-2- oxazoline) were dissolved from polyethylene nano- and microfibers with widths ranging from 500 nm to 10 microns and undetermined lengths (but typically greater than 1 mm in length). The fibers were isolated by filtration, washed with water, filtered, and suspended in isopropanol. Figure 4BAn image of the fiber is prov...

Embodiment 2

[0073] Example 2: Extruded polyethylene micro and nanofibers

[0074] The resulting material (1 gram) was mixed with poly(2-ethyl -2- oxazoline) (9 g) were combined and extruded to obtain nano and micro fibers. The processing conditions and properties of the nano and micro fibers are described in Table 1.

[0075] Can be combined with poly(2-ethyl-2- oxazoline) to process higher performance polymers into ultrafine fibers. Processable polymers include polyethylene, polypropylene, polylactide, polyolefin, polycycloolefin, polyester, polycaprolactone, polyperfluorocyclobutane, polyamide and other extrudable polymers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com