Process for machining wearing ring of cylinder liner of large low-speed marine diesel engine

A marine diesel engine and processing technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the cost of marine main engines and the amazing increase, and achieves solving micro deformation, reducing resonance amplitude, and eliminating stress deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

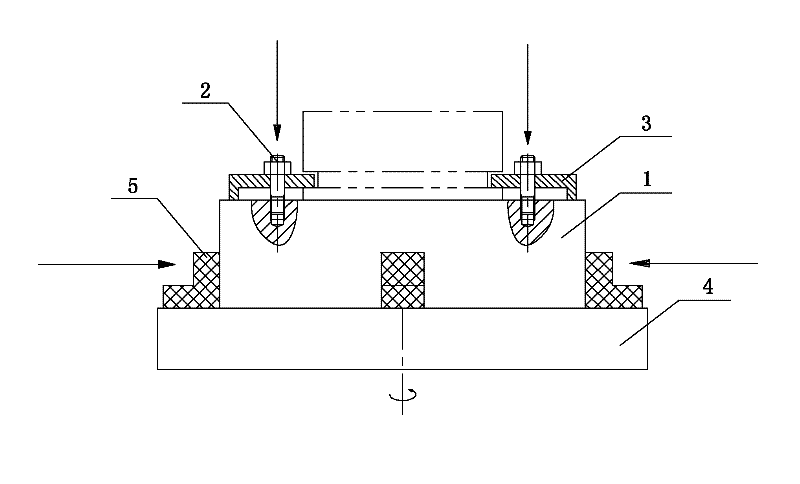

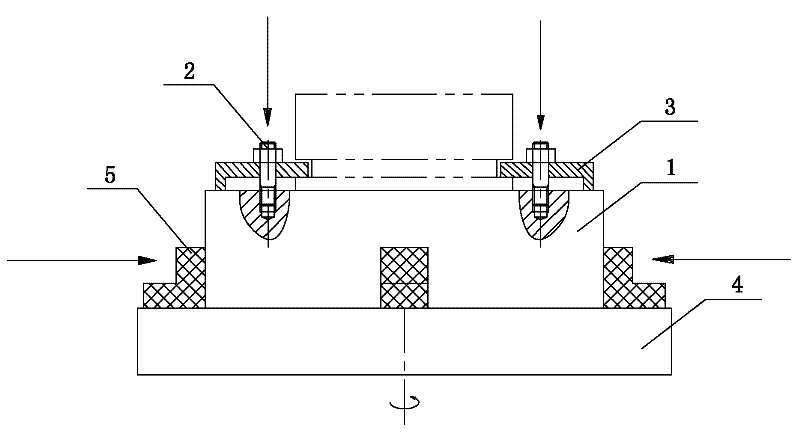

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] 7RTA72U-B marine diesel engine cylinder liner wear ring processing technology is as follows:

[0017] a. Select the outer diameter as Inner diameter is A 35CrMoA forging blank with a length of 165mm. In order to eliminate the stress effect generated in the turning process, the allowance of the inner and outer circles of the blank should not be too small.

[0018] b. Turn one end face of the wear-resistant ring blank of the cylinder liner flat, and turn out the outer circle to find the alignment ring; at a distance of 10mm from the flat end face of the car, process a 15mm wide and 10mm deep technological ring groove;

[0019] c. Clamping: clamp the above-mentioned workpiece on a vertical lathe through a new type of fixture, such as figure 1 As shown, the new fixture is provided with a circular platform 1, on which six evenly distributed equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com