Silicon-carbon composite material, preparation method thereof and cathode material containing same as well as lithium ion battery

A silicon-carbon composite material and composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance of negative electrode materials, difficulty in uniform dispersion, poor effect, etc., to improve silicon volume effect , Improve electrochemical stability, improve specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

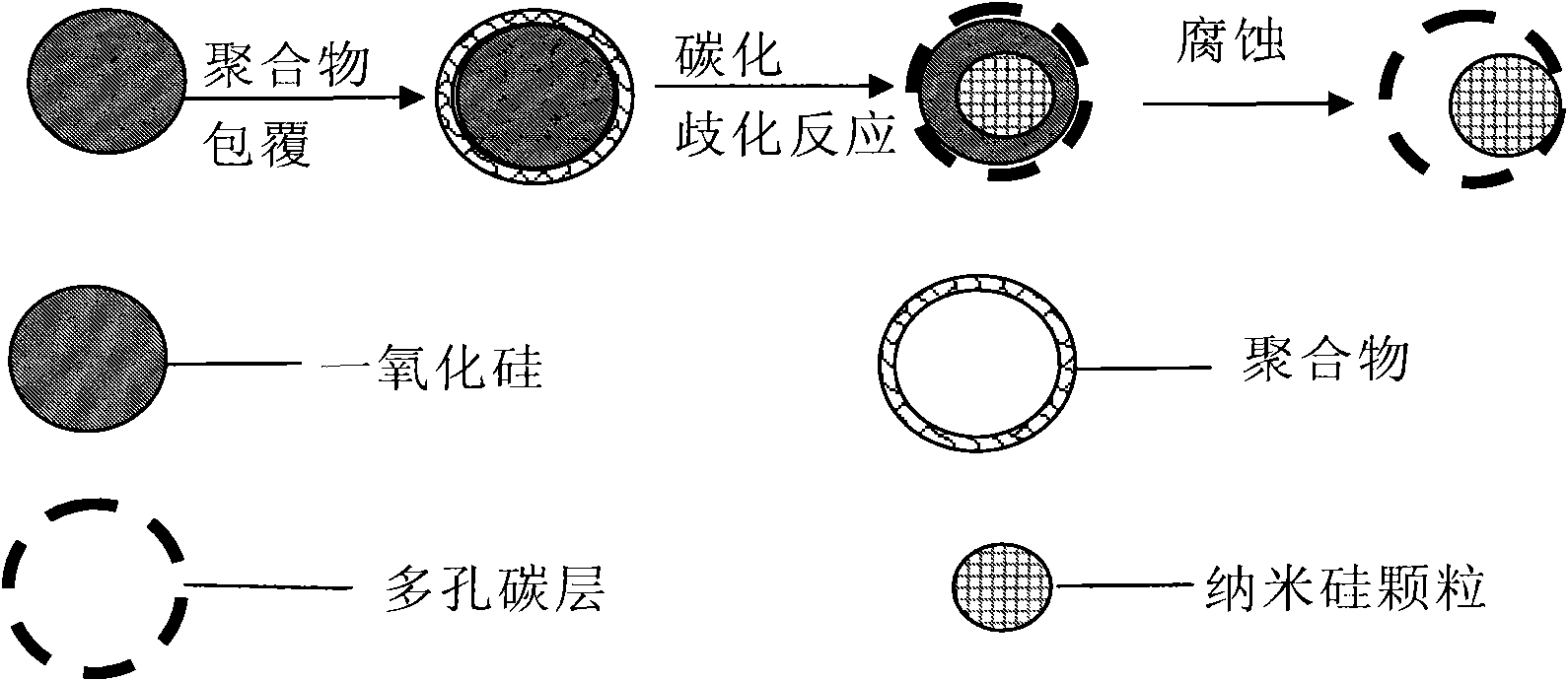

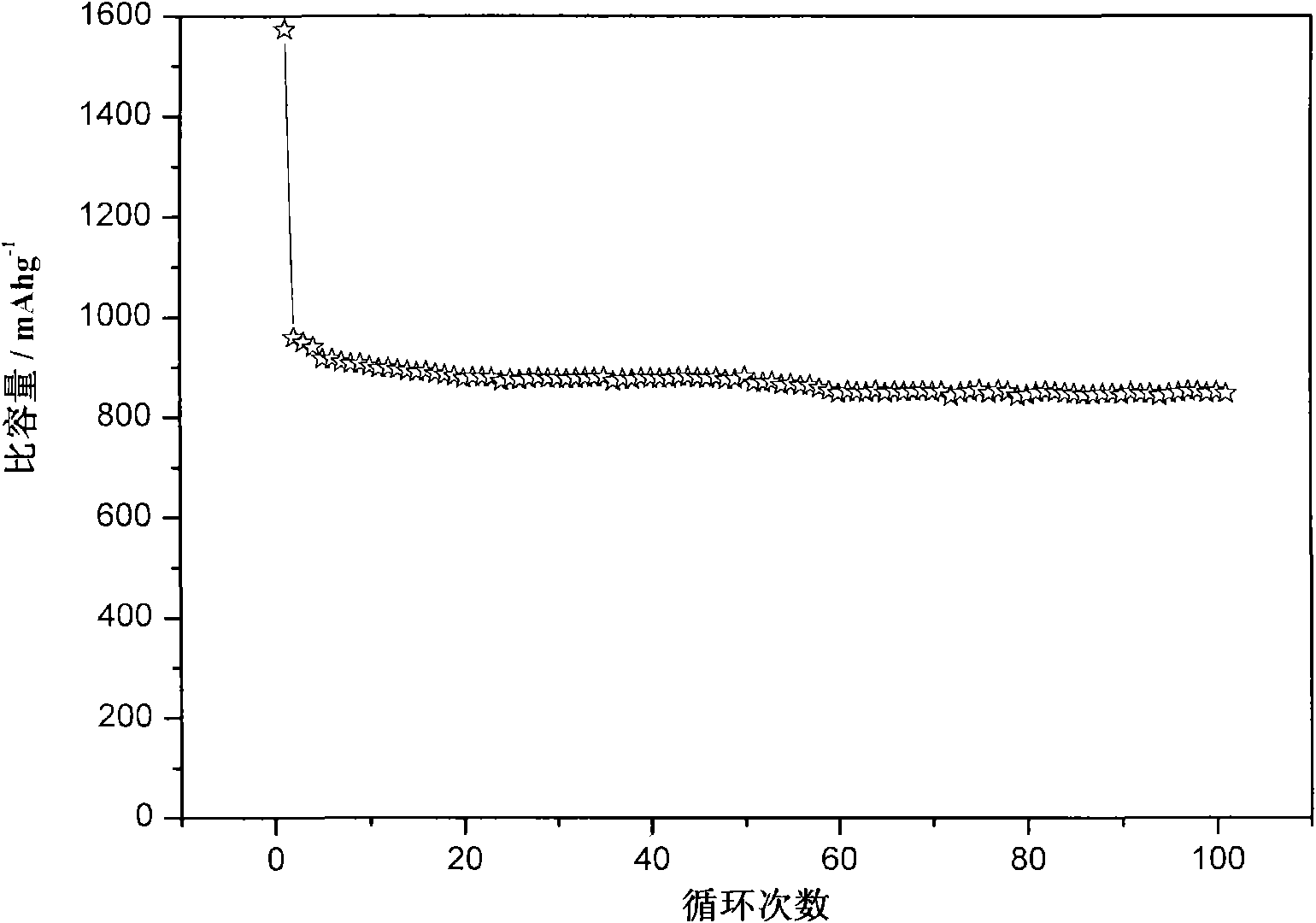

[0040] Weigh 0.4g of phenolic resin and dissolve it in 30mL of ethanol to obtain a polymer phenolic resin solution, then add 0.80g of silicon monoxide, and ultrasonically disperse for 10min to fully disperse silicon monoxide in the polymeric phenolic resin solution. After stirring and evaporating ethanol, a viscous mixture is obtained, which is a composite material coated with silicon monoxide by polymer phenolic resin, which is transferred to a porcelain boat and heated to 1000°C, heat preservation for 4 hours, during which the phenolic resin undergoes a carbonization reaction, and the silicon monoxide undergoes a disproportionation reaction. After cooling, take it out to obtain 1.0 g of a composite material of porous carbon-coated silica / nano-silicon particles.

[0041] Add the obtained composite material into 50mL 3wt% hydrofluoric acid solution, and filter out the resulting suspension after stirring continuously for 10h. During the stirring process, the silicon dioxide in t...

Embodiment 2

[0046] Weigh 1g of polyvinyl chloride and dissolve it in 30mL of chloroform, then add 0.80g of silicon monoxide, and ultrasonically disperse for 60min. After stirring and evaporating chloroform, a viscous mixture was obtained, which was transferred to a porcelain boat, heated to 900°C under the protection of argon, kept for 12 hours, and taken out after cooling to obtain 1.1g of porous carbon-coated silica / nano Composite material of silicon particles.

[0047] The obtained composite material was added to 25mL of 8wt% hydrofluoric acid solution, and after continuous stirring for 6 hours, the resulting suspension was filtered out, washed thoroughly with distilled water, and dried at 100°C for 12 hours to obtain 0.6g of silicon-carbon composite material.

[0048] The particle size of nano-silicon particles in the silicon-carbon composite material was measured by the same method as in Example 1, and the nano-silicon content was 43%.

[0049] The obtained silicon-carbon composite ...

Embodiment 3

[0052] Weigh 3.2g of polymethyl methacrylate and dissolve in 30mL of acetone, then add 0.80g of silicon monoxide, and ultrasonically disperse for 100min. After stirring and evaporating acetone, a viscous mixture was obtained, which was transferred to a porcelain boat, heated to 1050°C under the protection of argon, kept for 4 hours, and taken out after cooling to obtain 1.5g of porous carbon-coated silica and nano-silicon particles of composite materials.

[0053] The obtained composite material was added to 20 mL of 20 wt% hydrofluoric acid solution, and the suspension was filtered out after continuous stirring for 1 h, washed thoroughly with distilled water, and dried at 100° C. for 12 hours to obtain 0.9 g of silicon-carbon composite material.

[0054] Using the same method as in Example 1, the particle size of nano-silicon particles in the silicon-carbon composite material was measured to be 34 nm, and the nano-silicon content was 31%.

[0055] The obtained silicon-carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com