Residue soil improvement experimental device for shield method tunnel construction

A technology for muck improvement and tunnel construction, which is applied in measuring devices, using stable shear force to test material strength, testing wear resistance, etc. It can solve the problems of complicated test process, unsatisfactory test requirements, long test time, etc. , to achieve the effect of high reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

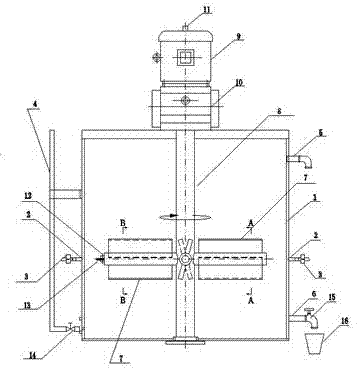

[0013] With reference to the accompanying drawings, a shield tunnel construction slag improvement experimental device consists of a steel cylinder 1, an injection port 2, a flow meter 3, a connector pipe 4, an overflow pipe 5, a drain pipe 6, a stirring blade 7, a stirring Shaft 8, motor 9, reducer 10, torque meter 11, test block fixing device 12, test block 13, connector pipe valve 14, drain pipe valve 15, measuring cup 16, the device is divided into two parts: test cylinder and stirring device, The test cylinder is composed of a steel cylinder 1, an injection port 2, a flow meter 3, a connector pipe 4, an overflow pipe 5 and a drain pipe 6. There are 4 injection ports 2 for the improved solution, which are evenly distributed on the steel cylinder at the position of the stirring blade. 1 wall; the stirring device is made up of stirring blade 7, stirring shaft 8, motor 9, speed reducer 10 and torque meter 11, and stirring blade 7 is connected on the stirring shaft 8 by four sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com