Process method for prolonging operation period of hydrogenation device

A technology of operation cycle and process method, which is applied in the petroleum industry, refining to remove heteroatoms, and treat hydrocarbon oil. It can solve the problems of catalyst bed blockage, reduce pressure drop, ensure production safety, and have a simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

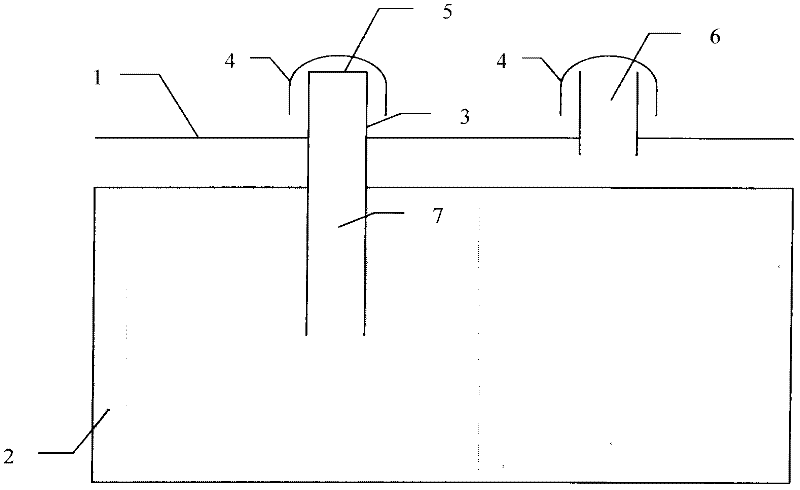

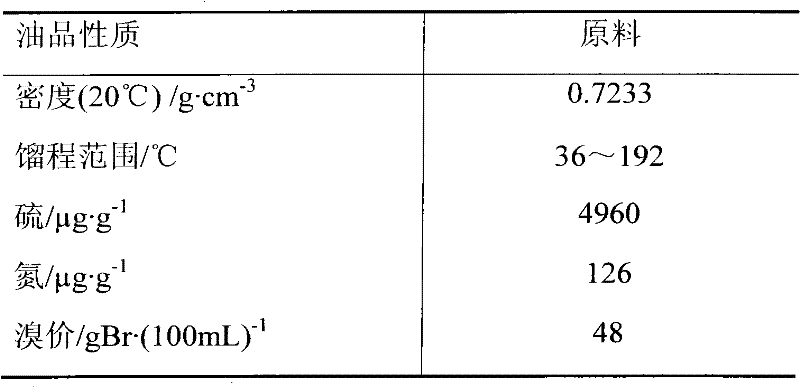

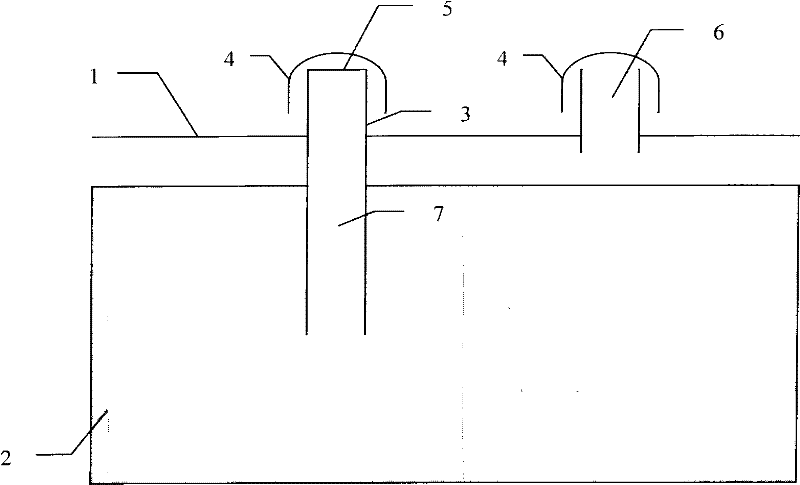

[0033] FHRS-1 (hydrogenation silicon scavenger), FZC-102B (hydrogenation protection agent) and FH-40C (main hydrorefining catalyst) developed and produced by Fushun Petrochemical Research Institute are used. according to figure 1 As shown in the schematic structure, the reactor is equipped with two catalyst beds, the first catalyst bed is filled with FHRS-1, and the long center pipe on the gas-liquid distribution plate extends downward to the middle of the bed. The second catalyst bed is filled with FZC-102B and FH-40C. The properties of raw oil are shown in Table 1, and the process conditions and product properties after 100 days of operation are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com