Balloon control ring on ring spinning machine

A technology of ring spinning machine and control ring, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problem that the actuating mechanism cannot be easily integrated into the spinning machine and block the balloon control ring And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

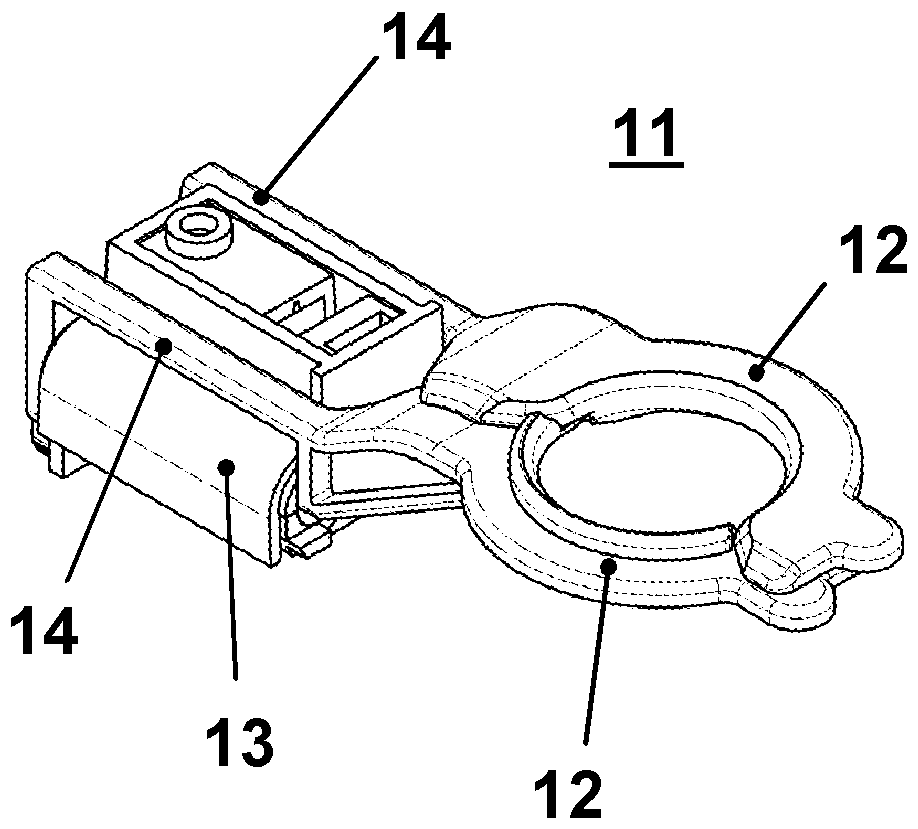

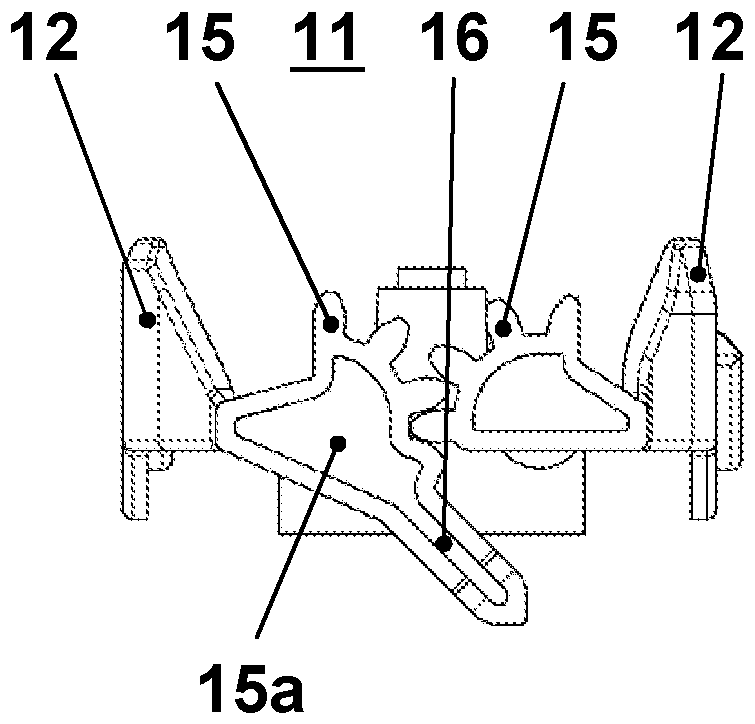

[0032] figure 1 A ring spinning machine 1 according to the invention is schematically shown with a plurality of adjacently positioned spinning stations 2 . The spinning station 2 is arranged in the head 3 along the longitudinal direction X of the ring spinning machine 1 1 and tail 3 2 between. Head 3 of ring spinning machine 1 1 and tail 3 2 Can contain bearings, drives, controls etc. necessary to operate the spinning machine. For example, if figure 1 As further seen on the two spinning stations 2 schematically shown in , each spinning station 2 consists of a roving bobbin 4 located above a drafting system 5 on which a roving 6 is wound. The roving 6 extends from the roving bobbin 4 across a drafting system 5 where the roving is drawn and then guided to a yarn forming element. The endless traveler or ring traveler winds the finished yarn onto the bobbin 7 . Cops 7 are mounted on spindles 8 . figure 1 Also shown are the spindle guide 9 and the ring guide 10 . A balloo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com