High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

A polyvinylidene fluoride resin, polyvinylidene fluoride technology, applied in the direction of coating, etc., to achieve the effect of slow termination, significant automatic acceleration effect, and high molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

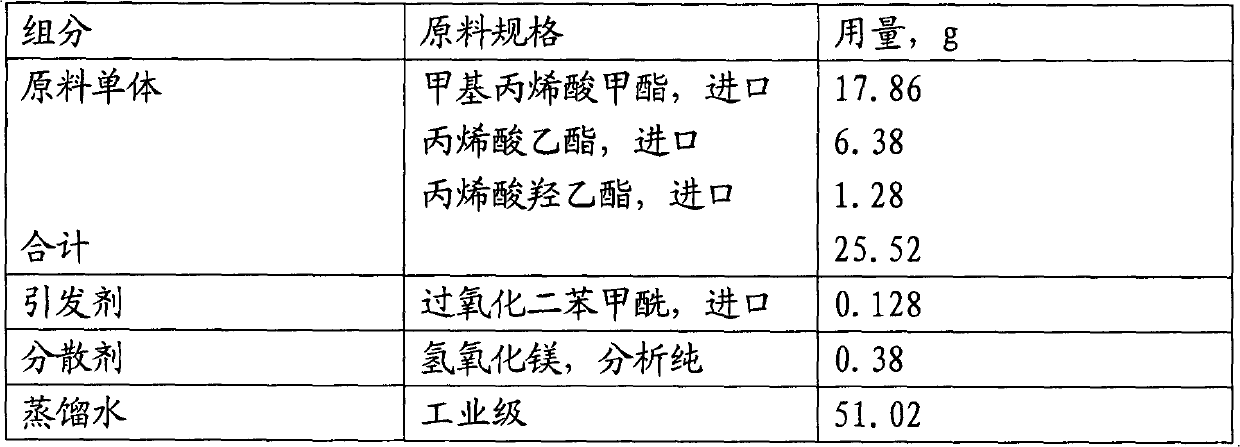

[0017] ① See Table 1 for the amount of raw materials.

[0018] Table 1

[0019]

[0020] ②Specific operation of suspension polymerization

[0021] Add distilled water into the reaction vessel, add inorganic dispersant and heat up to 70°C under stirring and nitrogen flow, then add the homogeneous mixture of raw material monomers and initiators, keep the temperature at 80°C for 6 to 7 hours, then heat up to After heat preservation reaction at 90°C for 1 hour, cool down to 30°C, add 22.95 grams of dilute acid (5wt% sulfuric acid), and react for 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles, which are high molecular weight acrylic acid Resin B-1. The Mn of the B-1 resin measured by gel permeation chromatography is 137116; the Mw is 166213; and the Mw / Mn is 1.21.

Embodiment 2

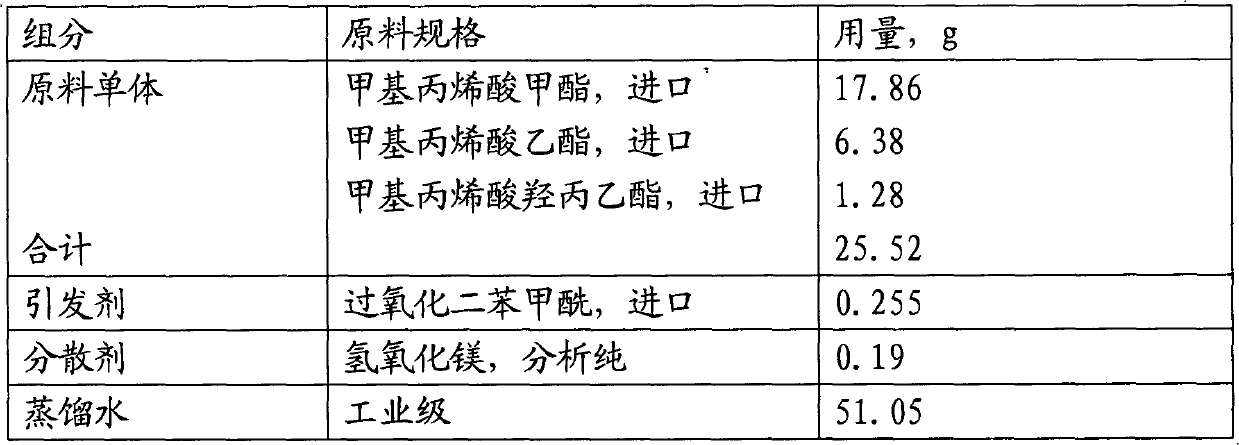

[0023] ① See Table 2 for the amount of raw materials.

[0024] Table 2

[0025]

[0026] ②Specific operation of suspension polymerization

[0027] Add distilled water into the reaction vessel, add inorganic dispersant and raise the temperature to 70°C under stirring and nitrogen gas, then add the homogeneous mixture of raw material monomers and initiators, keep the temperature at 80°C for 5 to 6 hours, then heat up to After heat preservation reaction at 90°C for 1 hour, cool down to 30°C, add 22.97 grams of dilute acid (5wt% sulfuric acid), and react for 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles that are high molecular weight acrylic acid Resin B-2. The Mn of the B-2 resin measured by gel permeation chromatography is 112938; the Mw is 171944; and the Mw / Mn is 1.52.

Embodiment 3

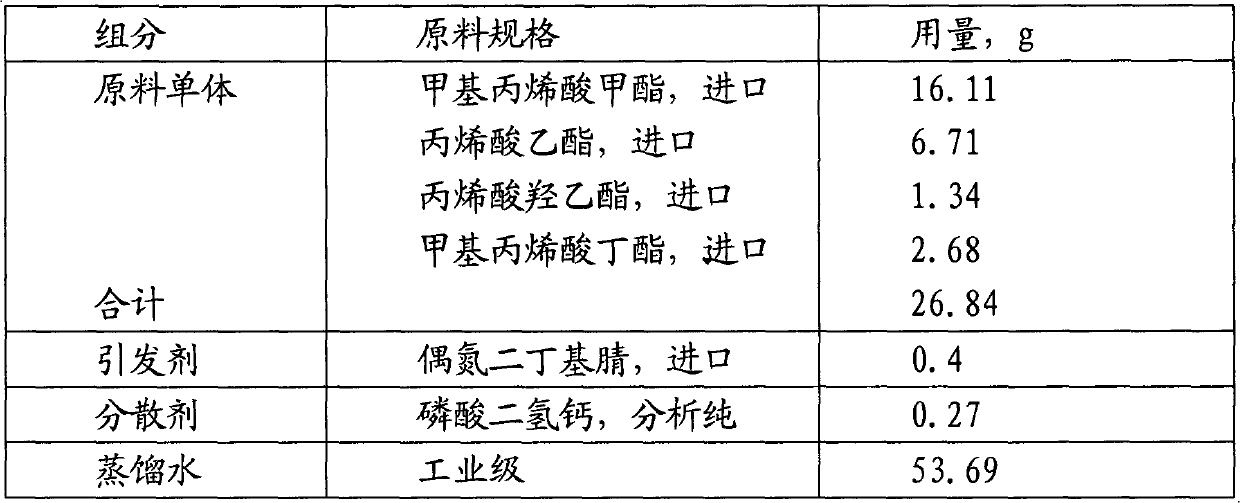

[0029] ① See Table 3 for the amount of raw materials.

[0030] table 3

[0031]

[0032] ②Specific operation of suspension polymerization

[0033] Add distilled water into the reaction vessel, add inorganic dispersant and raise the temperature to 70°C under stirring and nitrogen gas, then add the homogeneous mixture of raw material monomers and initiators, keep the reaction at 80°C for 5 to 6 hours, then cool down to At 30°C, add 18.79 grams of dilute acid (4wt% phosphoric acid), react for another 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles that are high molecular weight acrylic resin B-3. The Mn of the B-3 resin measured by gel permeation chromatography is 97365; the Mw is 160517; and the Mw / Mn is 1.65.

[0034] (2) Preparation of coil topcoat

[0035] In order to investigate the performance of the high-molecular-weight acrylic resin of the present invention, the acrylic resin of the present invention (embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com