High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

A technology of polyvinylidene fluoride resin and polyvinylidene fluoride, applied in the direction of coating, etc., to achieve the effects of difficult control of reaction temperature, high molecular weight distribution, and remarkable automatic acceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

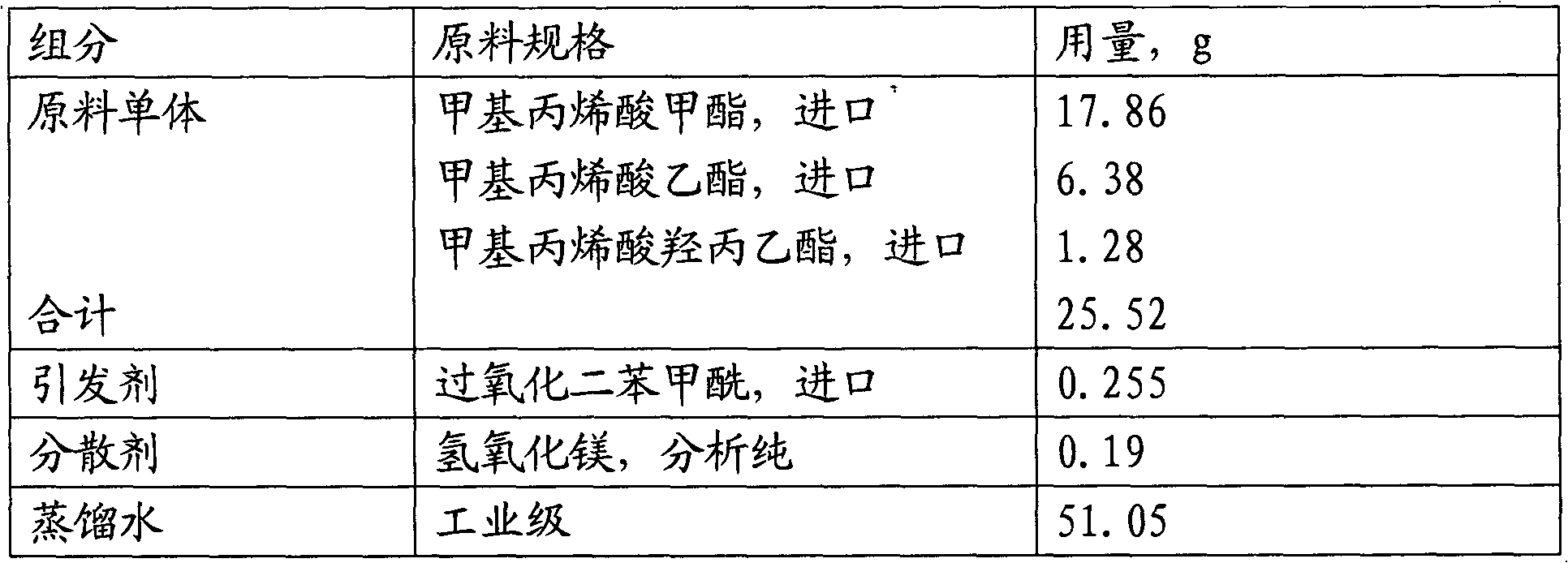

[0017] ① See Table 1 for the amount of raw materials.

[0018] Table 1

[0019]

[0020] ②Specific operation of suspension polymerization

[0021] Add distilled water into the reaction vessel, add inorganic dispersant and heat up to 70°C under stirring and nitrogen flow, then add the homogeneous mixture of raw material monomers and initiators, keep the temperature at 80°C for 6 to 7 hours, then heat up to After heat preservation reaction at 90°C for 1 hour, cool down to 30°C, add 22.95 grams of dilute acid (5wt% sulfuric acid), and react for 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles, which are high molecular weight acrylic acid Resin B-1. The Mn of the B-1 resin measured by gel permeation chromatography is 137116; the Mw is 166213; and the Mw / Mn is 1.21.

Embodiment 2

[0023] ① See Table 2 for the amount of raw materials.

[0024] Table 2

[0025]

[0026] ②Specific operation of suspension polymerization

[0027] Add distilled water into the reaction vessel, add inorganic dispersant and raise the temperature to 70°C under stirring and nitrogen gas, then add the homogeneous mixture of raw material monomers and initiators, keep the temperature at 80°C for 5 to 6 hours, then heat up to After heat preservation reaction at 90°C for 1 hour, cool down to 30°C, add 22.97 grams of dilute acid (5wt% sulfuric acid), and react for 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles that are high molecular weight acrylic acid Resin B-2. The Mn of the B-2 resin measured by gel permeation chromatography is 112938; the Mw is 171944; and the Mw / Mn is 1.52.

Embodiment 3

[0029] ① See Table 3 for the amount of raw materials.

[0030] table 3

[0031]

[0032] ②Specific operation of suspension polymerization

[0033] Add distilled water into the reaction vessel, add inorganic dispersant and raise the temperature to 70°C under stirring and nitrogen gas, then add the homogeneous mixture of raw material monomers and initiators, keep the reaction at 80°C for 5 to 6 hours, then cool down to At 30°C, add 18.79 grams of dilute acid (4wt% phosphoric acid), react for another 10 minutes, then filter, wash with water, discharge, and dry to obtain bead-like transparent particles that are high molecular weight acrylic resin B-3. The Mn of the B-3 resin measured by gel permeation chromatography is 97365; the Mw is 160517; and the Mw / Mn is 1.65.

[0034] (2) Preparation of coil topcoat

[0035] In order to investigate the performance of the high-molecular-weight acrylic resin of the present invention, the acrylic resin of the present invention (embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com