Production process for laminating hot melt adhesive with TPU (thermoplastic urethane)

A production process, hot-melt adhesive technology, applied in the field of hot-melt adhesive production process, can solve the problems of poor flatness, unevenness, beauty, bubbles and wrinkles of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

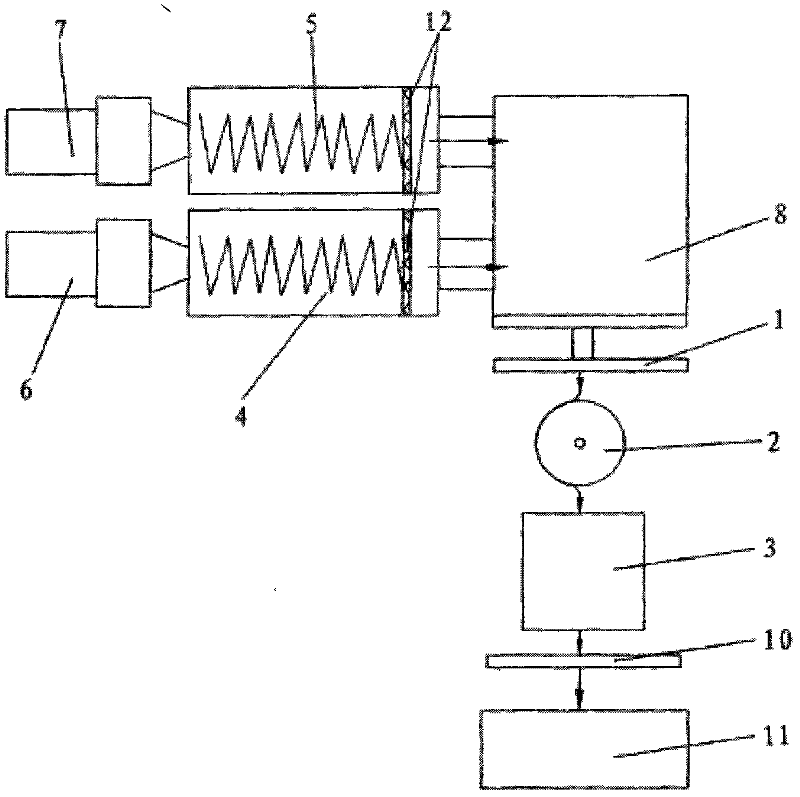

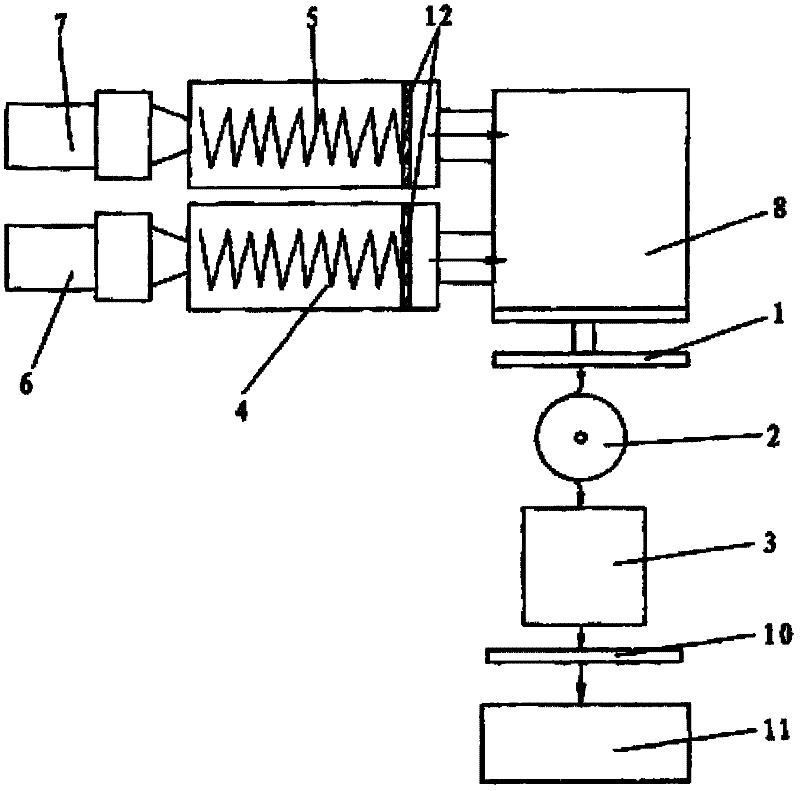

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] A kind of production technique of hot-melt adhesive bonding TPU of the present invention, it comprises the following steps:

[0025] Step A, prepare hot melt adhesive raw material and TPU raw material;

[0026] Step B, if the double-layer co-extrusion extruder is selected, first set the set temperature value of the double-layer co-extrusion extruder during production, the double-layer co-extrusion extruder starts to heat up, when the temperature reaches the set temperature value, the double-layer co-extrusion The screw of the layer co-extrusion extruder starts to work and enters step C; if a single extruder is selected, first set the set temperature value of the single extruder production, and the single extruder starts to heat up, when the temperature reaches the set temperature value Finally, the screw of the single extruder starts to work and enters step D; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com