Method for preparing Fe/Al micro-nano composite powder

A composite powder, micro-nano technology, applied in liquid chemical plating, coating, metal material coating technology and other directions, can solve the problems of instability, plating solution decomposition, increase the difficulty of the preparation process, etc., and achieve increased weight gain rate. , The effect of uniform coating and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

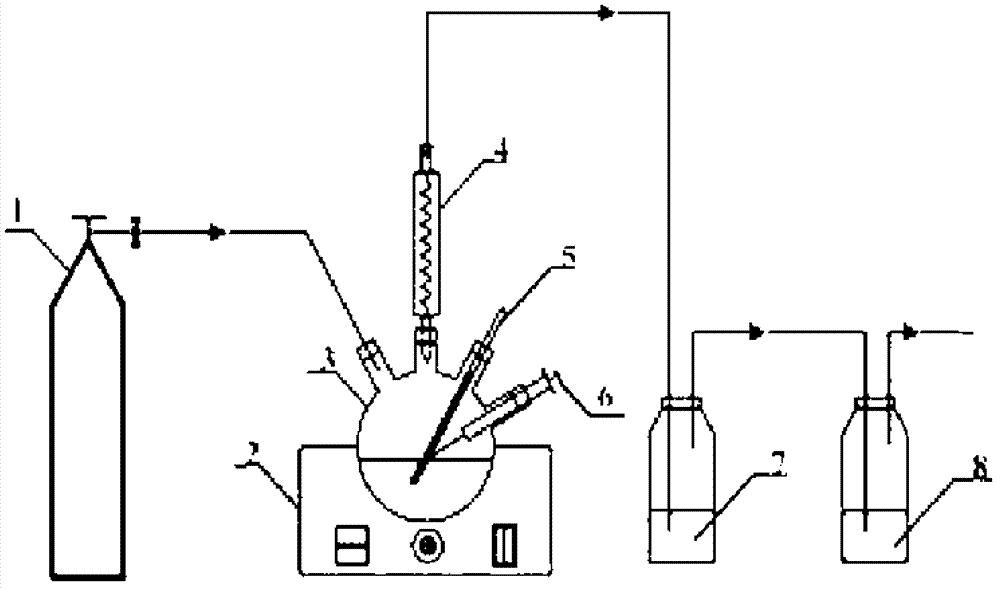

Method used

Image

Examples

Embodiment 1

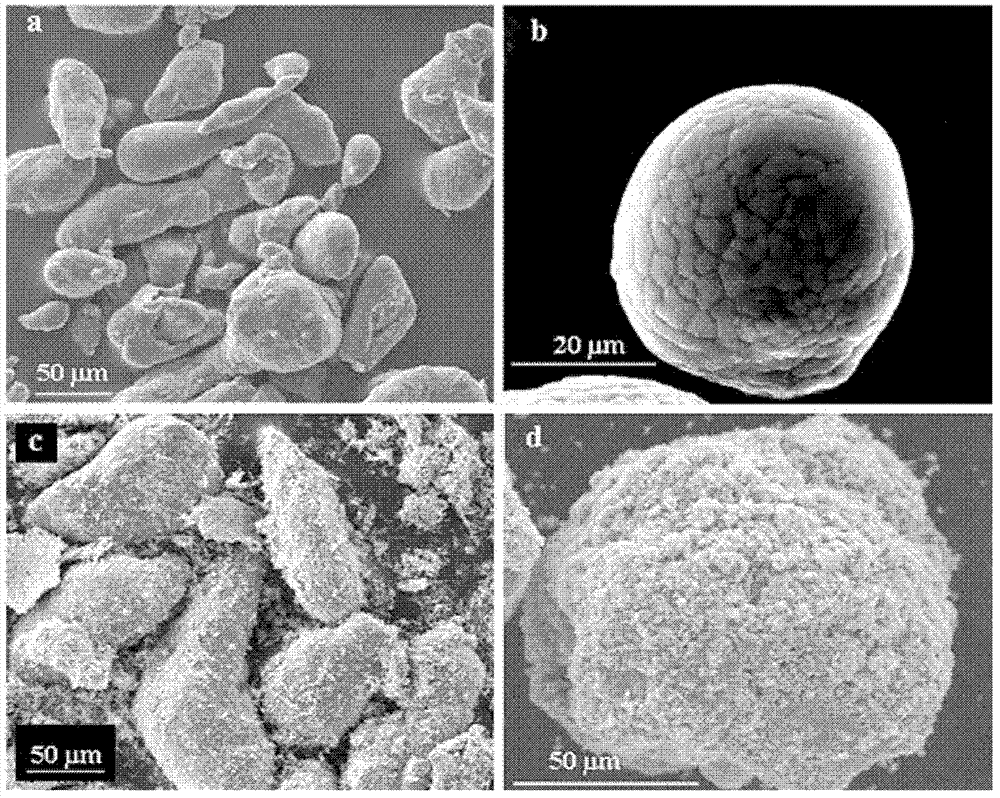

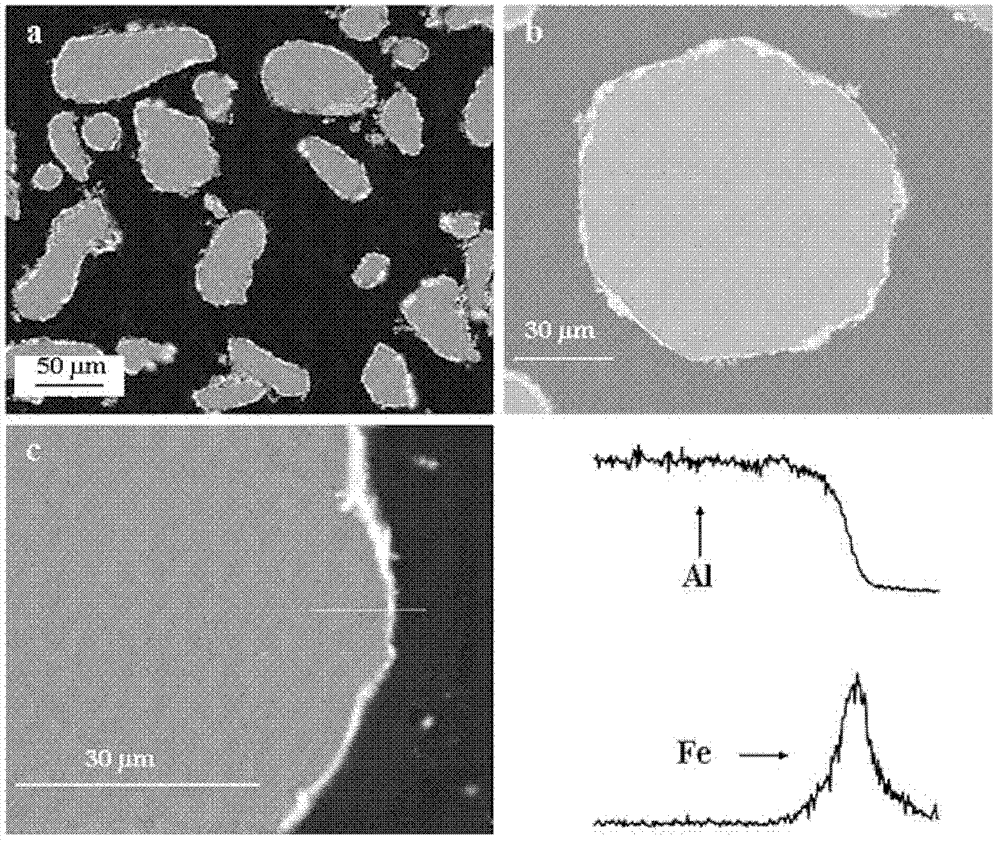

[0022] The present invention uses kerosene as a reagent, and at temperatures of 180, 240, and 300° C., utilizes carbonyl iron to decompose to generate iron particles to coat micron aluminum. In the experiment, we have done several experiments with different Fe / Al molar ratios; the following details Taking the cladding with Fe / Al molar ratio of 0.5:1 at a temperature of 180°C as an example, the process and cladding effect will be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com