Method for controlling flying shears for bars and wires based on T400

A control method and flying shear control technology, which is applied to rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem that the clutch flying shear cannot meet high-speed shearing, the impact of the clutch and brake parts is large, and the maintenance workload is large and other problems, to achieve the effect of fast and precise cutting edge position control, simplified control structure, and convenient upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0038] The T400-based flying shear control method provided by the present invention is an advanced electric control method for rod and wire flying shear, and specifically includes the following steps:

[0039] 1. Flexible cutting mode selection:

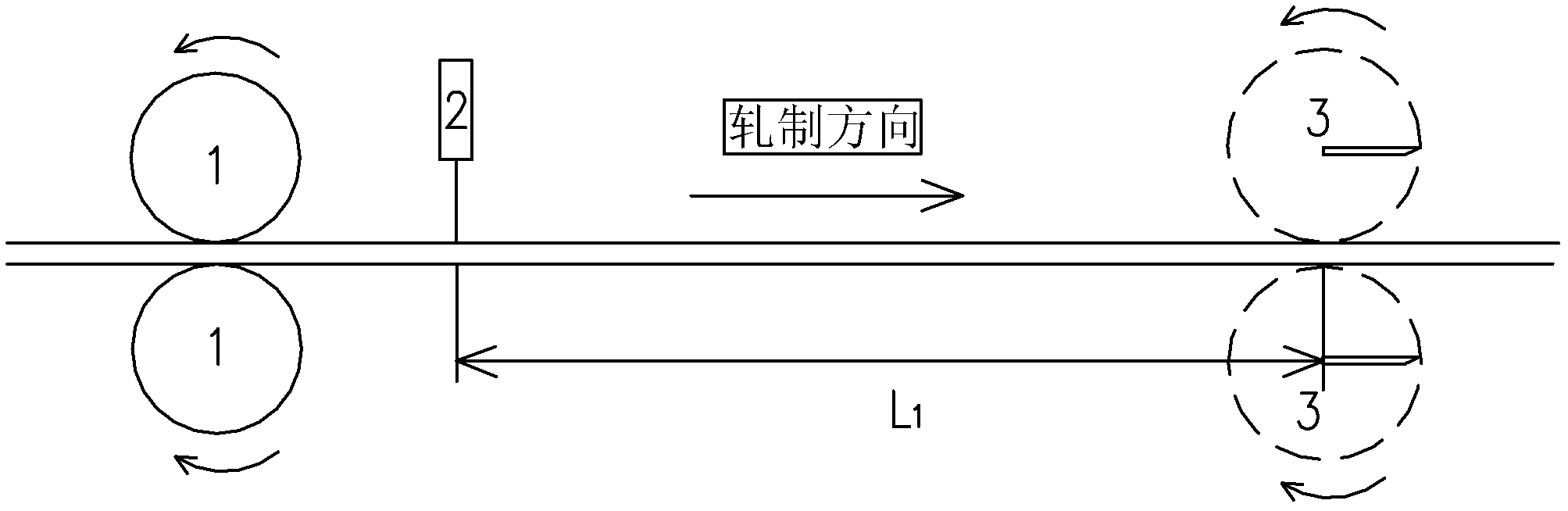

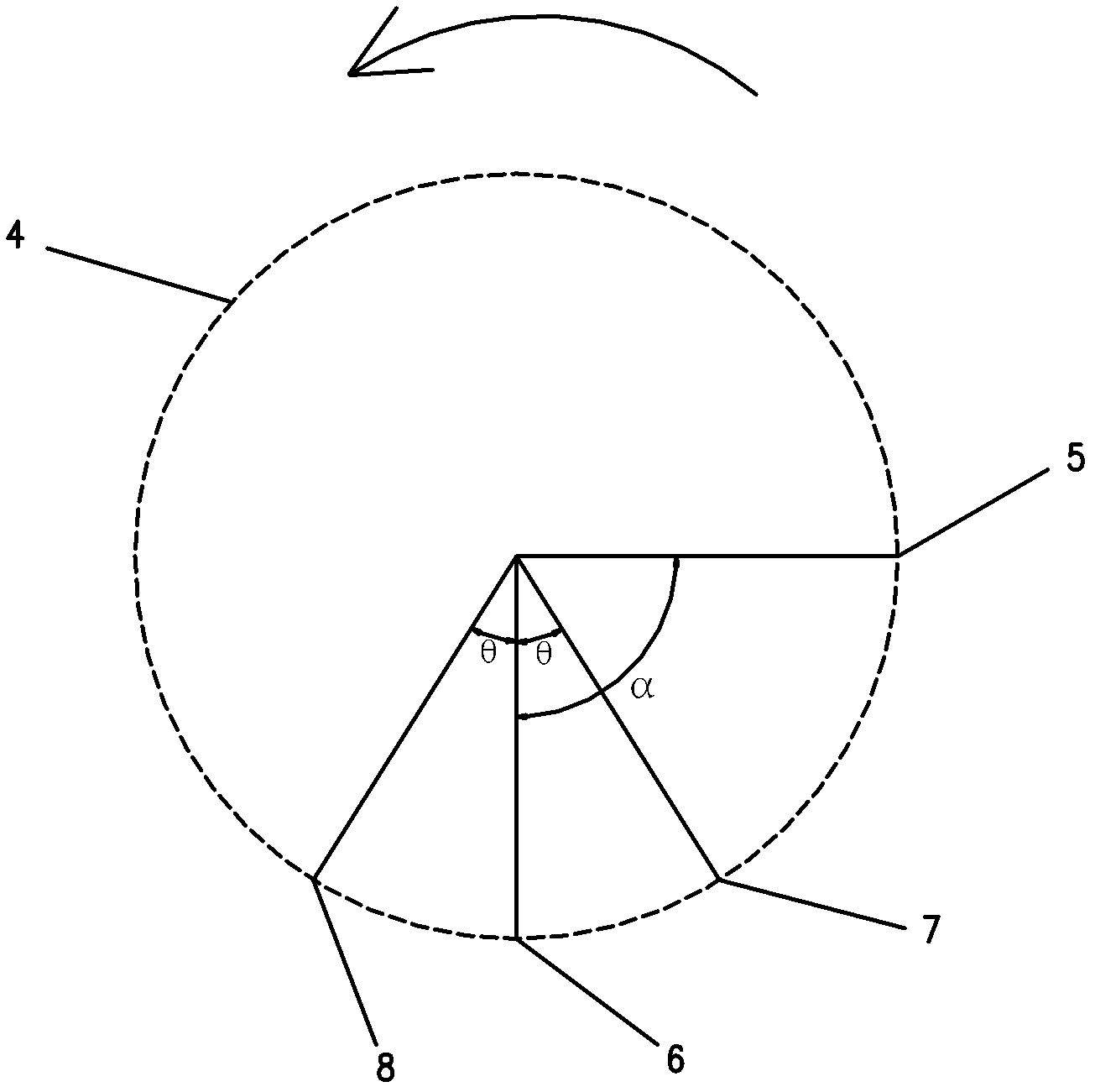

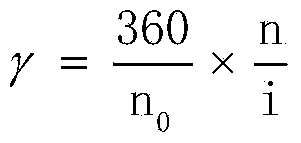

[0040] Flying shears for rods and wires mainly have the following three mechanical structures: rotary type, crank-connecting rod type and crank-connecting rod flywheel type. First, check the mechanical structure of the flying shear on the screen, and the flying shear controller T400 will automatically read the parameters of the corresponding mechanical structure and automatically switch to the flying shear control model of the corresponding mechanical structure.

[0041] Flying shears mainly have the following cutting functions: head cutting, tail cutting, double-length cutting, section cutting, automatic onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com