Catalyst for storing hydrogen by organic matter carrier and preparation method of catalyst

A catalyst and organic technology, applied in the field of dehydrogenation catalyst and its preparation, can solve the problems of low dehydrogenation conversion rate, easy deactivation of catalyst, high dehydrogenation temperature, and achieve high microporosity and pore volume, excellent catalytic performance, The effect of excellent hydrothermal stability and acidic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

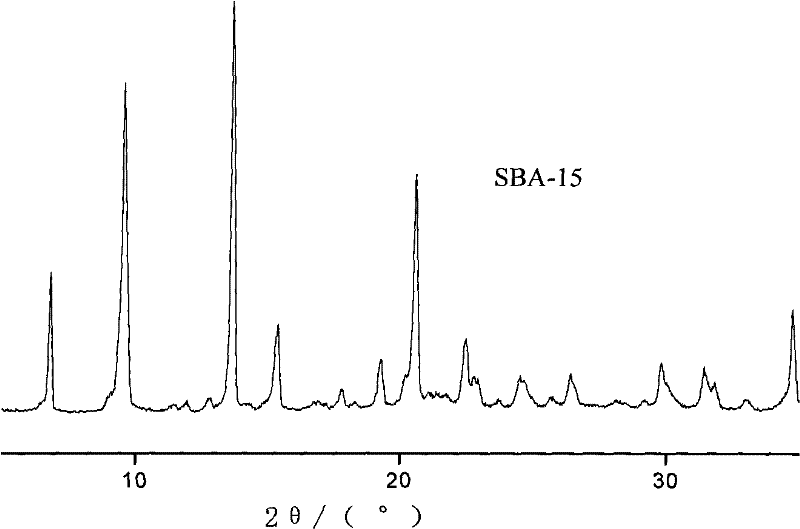

[0055] Immerse SBA-15, SBA-16, MCM-41, MCM-22, MCM-49, SAPO-11, SAPO-41 containing rare earth metals (in the framework) respectively in chloroplatinic acid containing active metals (pH value should be controlled In 3, the platinum content is 3.0%), after soaking for 12 hours, leach out, and after drying at 100°C for 6 hours, put it into a round bottom flask and feed nitrogen gas, and add metered KBH drop by drop 4 -KOH solution reduction, until no more gas is released in the system, and then washed repeatedly with distilled water, then stored in absolute ethanol. The XRD pattern of the catalyst supported by SBA-15 is as follows figure 1 shown.

Embodiment 2

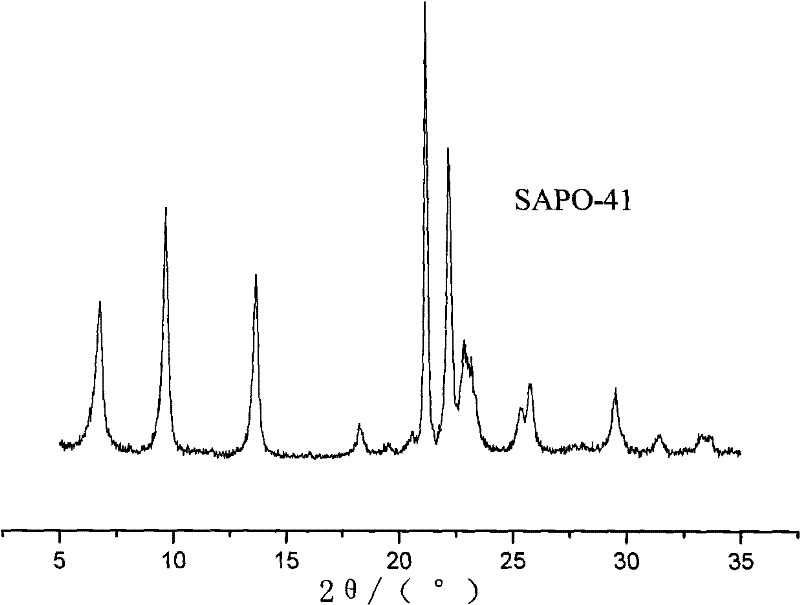

[0057] Immerse SBA-15, SBA-16, MCM-41, MCM-22, MCM-49, SAPO-11, SAPO-41 containing rare earth metals (in the framework) into the active metal palladium chloride or nitrate aqueous solution (pH value should be controlled between 4, palladium content 3.0%), leach after soaking for 12 hours, after drying at 120°C for 3 hours, put into a round bottom flask and feed nitrogen, add metered KBH drop by drop 4 -KOH solution reduction, until no more gas is released in the system, and then washed repeatedly with distilled water, then stored in absolute ethanol. The XRD pattern of the catalyst supported by SAPO-41 is as follows figure 2 shown.

Embodiment 3

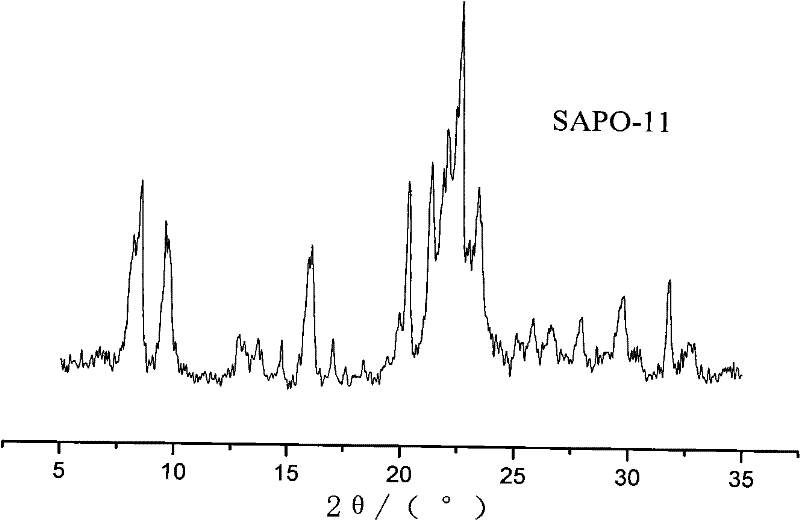

[0059] The SBA-15, SBA-16, MCM-41, MCM-22, MCM-49, SAPO-11, SAPO-41 containing rare earth metals (in the framework) were respectively immersed in the aqueous solution containing the active metal ruthenium chloride (pH It should be controlled at 3, the ruthenium content is 3.0%), soaked for 12 hours, drained, dried at 110°C for 4 hours, put into a round bottom flask and fed with nitrogen, and added the measured KBH dropwise 4 -KOH solution reduction, until no more gas is released in the system, and then washed repeatedly with distilled water, then stored in absolute ethanol. The XRD pattern of the catalyst supported by SAPO-11 is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com