Nondestructive grading method for lamb carcass output

A carcass and yield technology, applied in the field of non-destructive grading of sheep carcass yield, can solve problems such as damage and error carcass, and achieve the effects of avoiding human error, fast analysis speed, and good prediction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, sheep carcass meat production rate manual prediction model construction

[0040] 1.1 Test materials and instruments

[0041] 1.1.1 Test material

[0042] According to the national standard "GB / T 20551-2006 HACCP Application Specification for Livestock and Poultry Slaughter", the sheep carcasses are slaughtered and processed according to the provisions of Appendix E Standard Operating Procedures for Cattle and Sheep Slaughter, and hold the quarantine certificate issued by the animal epidemic prevention supervision agency of the place of origin.

[0043] 1.1.2 Test equipment

[0044] Planimeter: digital planimeter KP-90N, produced by Koizumi, Japan;

[0045] Color difference meter: Minolta CR-400, produced by Konica Corporation of Japan;

[0046] Electronic weighing platform scale: BSWE-1-60, Taiwan Lianmao Electronics Co., Ltd.;

[0047] Electronic digital caliper: 0-150mm, Shanghai Taihai Engineering Measuring Tools Co., Ltd.

[0048] 1.2 Test method ...

Embodiment 2

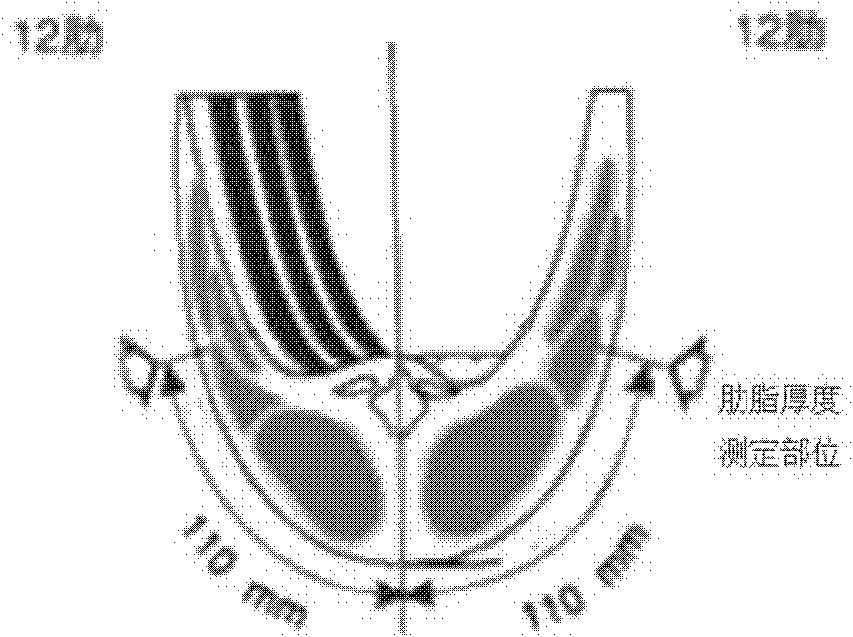

[0100] Example 2. Construction of a near-infrared spectrum prediction model for rib fat thickness and non-destructive grading of sheep carcass yield based on the model

[0101] Firstly, sheep carcasses with different rib fat thickness ranges were selected in the mutton processing workshop to measure the value of the rib fat thickness. The measurement site was the fat thickness at 11 cm from the 12 ribs of the lamb carcass to the center of the spine.

[0102] At the same time, a portable near-infrared probe was used to collect near-infrared spectra of corresponding parts (scanning range 1000nm-1800nm). Test conditions: 32 near-infrared spectrum scans; spectral resolution ≤ 12nm; experimental temperature 25°C. Collect 5 spectra for each sample to establish a spectral library, such as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com