In-line synthesis type high-pressure oil supply pump control system

A technology of control system and fuel supply pump, applied in charging system, engine control, fuel injection control and other directions, can solve the problems of high technical requirements, difficult production, complex structure, etc., and achieves simple processing technology, low manufacturing cost and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

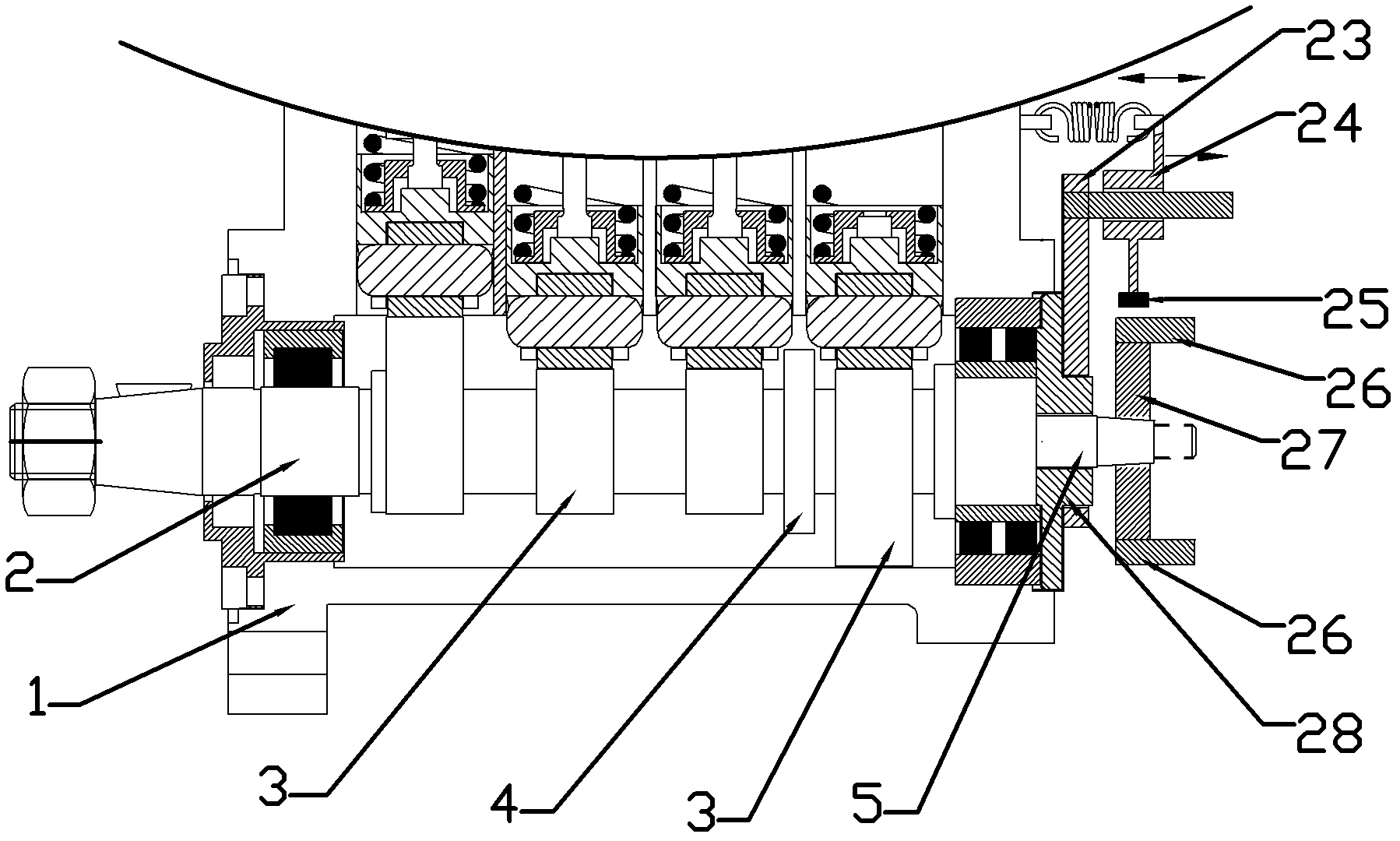

[0032] Such as figure 1 , this kind of in-line synthetic high-pressure oil supply pump control system includes an integral pump body 1, the drive shaft 2 is rotatably arranged on the integral pump body through bearings, the front cover of the oil supply pump, and the rear cover 28 of the oil supply pump, and the middle part of the drive shaft is set There are cams 3 matched with the plunger pumps, and the plunger pumps only provide high-pressure oil for the electronically controlled fuel injectors.

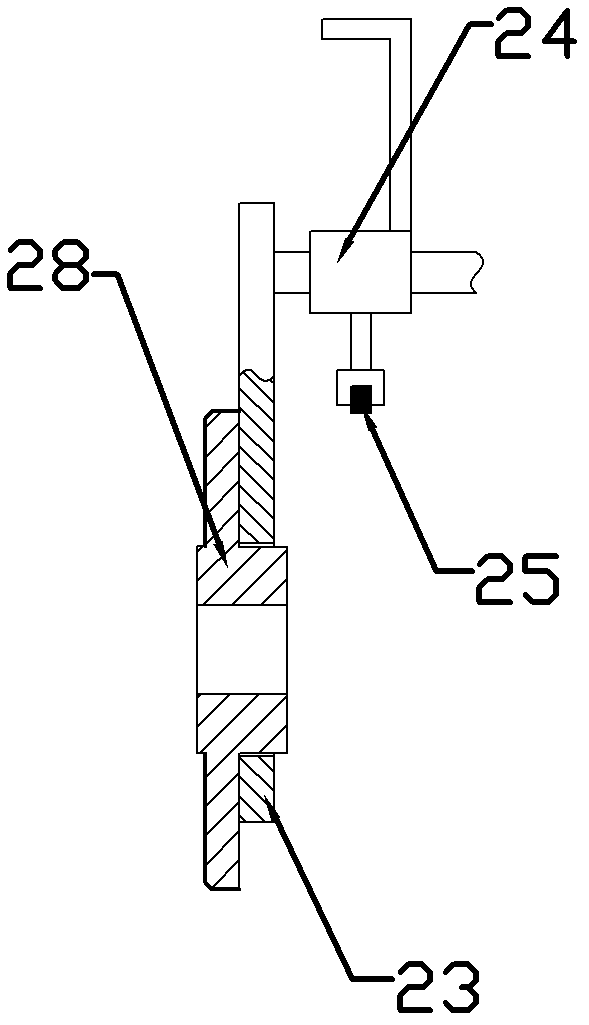

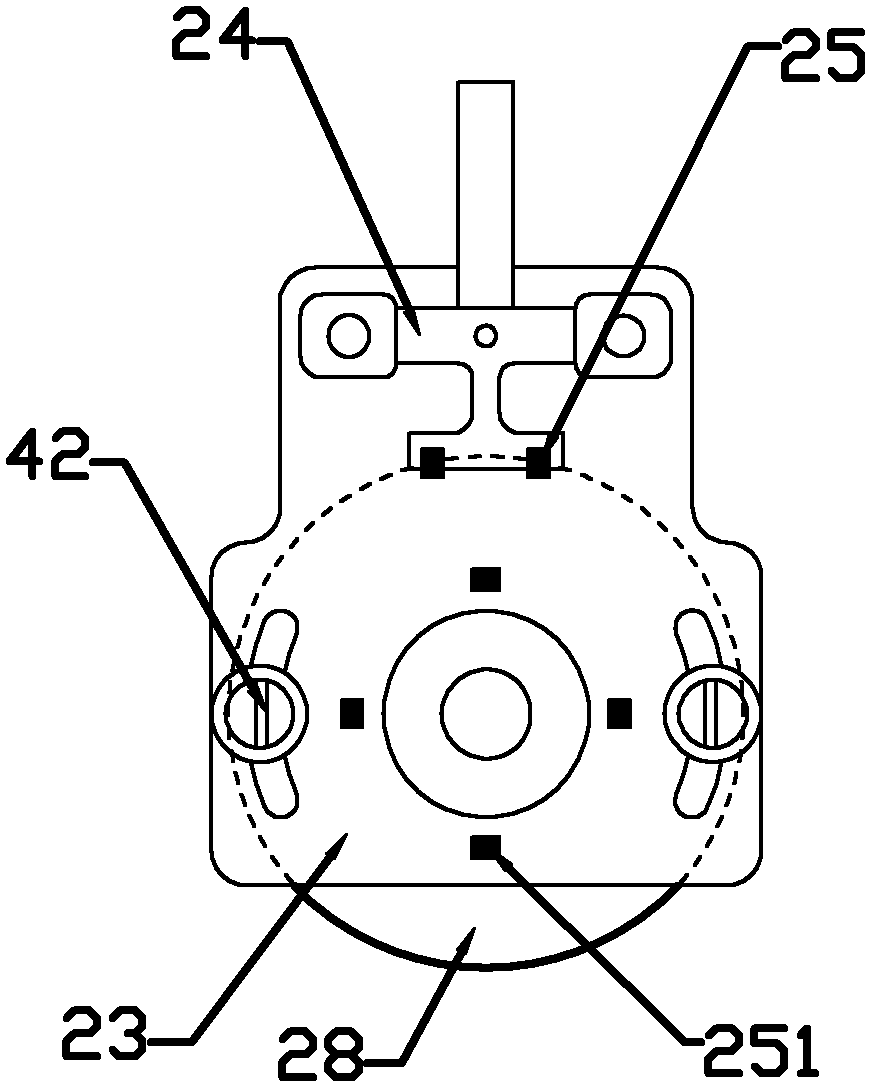

[0033] Such as figure 1 , figure 2 , image 3 The part of the drive shaft 2 protruding from the rear cover 28 of the fuel supply pump is the rotor shaft 5. The circular hole of the signal adjustment plate 23 is matched with the cylinder on the rear cover 28 of the fuel supply pump. The adjusting plate fastening bolt 42 is connected with the rear cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com