Method for integral ground manufacture, suspension and construction of large-sized steel trestle conveying system

A conveying system and overall production technology, which is applied in the construction, building structure, processing of building materials, etc., can solve the problems of large amount of work at height, high construction cost, low construction efficiency, etc., to improve work efficiency and reduce engineering costs. cost, the effect of ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The whole method of making and hoisting the ground of the large-scale steel trestle conveying system of the present invention is constructed according to the following steps:

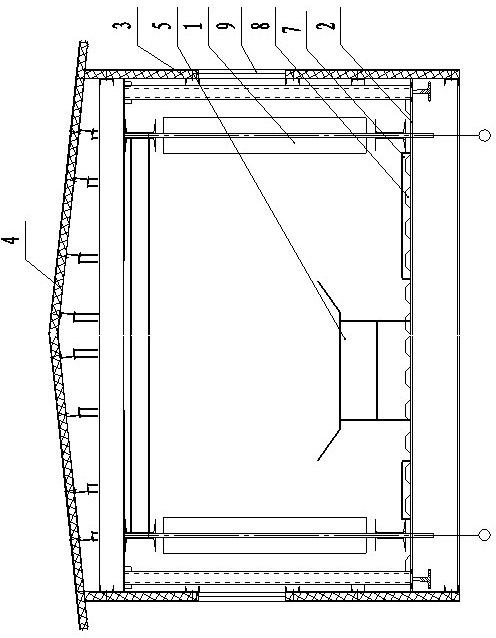

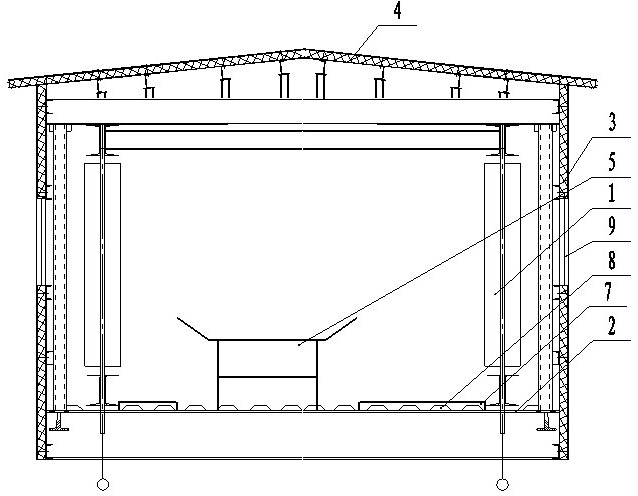

[0020] In the first step, the ground is made, such as figure 1 As shown, all processes such as the production of the steel truss 1 of the steel trestle bridge, the paving of the bottom plate 2, the enclosure of the wall plate 3, the sealing of the roof plate 4, and the installation of the intermediate frame 5 of the belt conveyor are all completed and assembled on the ground;

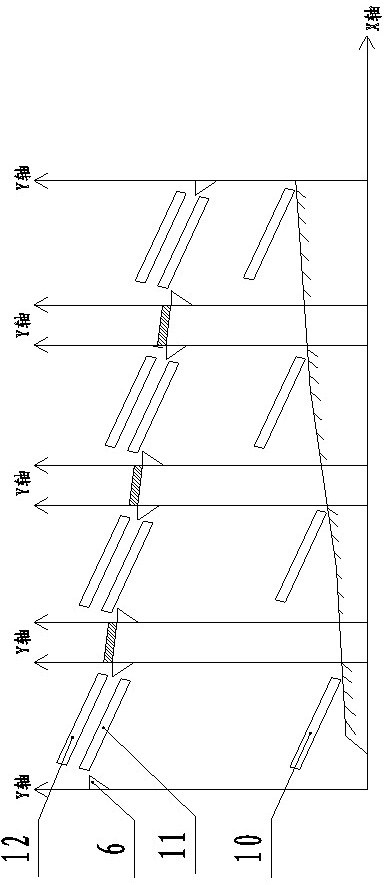

[0021] The second step is to hoist in place, establish a mathematical three-dimensional coordinate system, determine the spatial coordinates of the end points of the steel trestle when the steel trestle crosses obstacles 6, and use the coordinate guidance method to hoist the steel trestle in place as a whole;

[0022] The third step is to connect and fix the whole steel trestle bridge on the concrete corbel support with bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com