Use of product of low-temperature gasification of liquid dimethyl ether

A dimethyl ether, liquid technology, applied in one field, can solve problems such as low cleanliness, and achieve the effects of improving the environment, saving electric energy, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

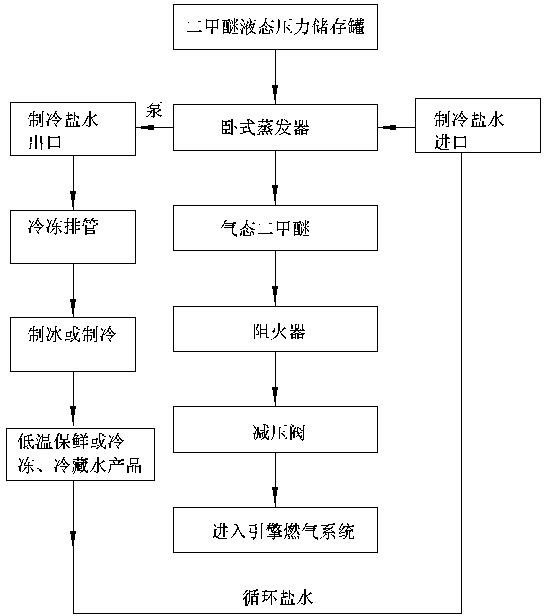

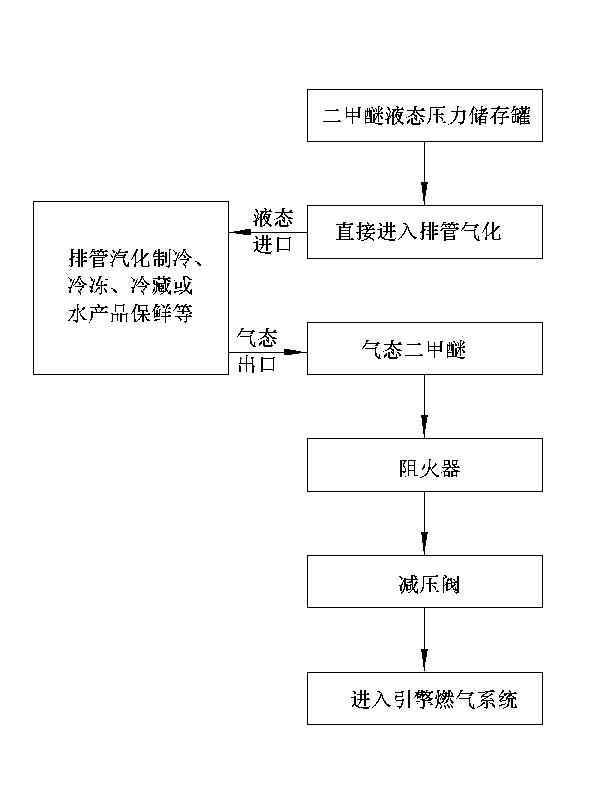

Method used

Image

Examples

Embodiment 1

[0048] There are thousands of 50-100kw power boats in a fishery base in the East China Sea. They go out early and return late every day. They are not satisfied with the freshness of small seafood in three seasons of the year because there is no cold source in the fish tank. DME gas engines are used instead of diesel engines. , working 10 hours a day. Diesel consumption is more than 114 kg / day, and the annual fuel consumption is more than 41.61 tons.

[0049] 1. Since the theoretical mixture gas calorific value of dimethyl ether gas and air is 5% higher than that of diesel, the power of the dimethyl ether gas engine is higher than that of the diesel engine. It vaporizes dimethyl ether at a ratio of 1:1 and vaporizes 114 kg of dimethyl ether per day;

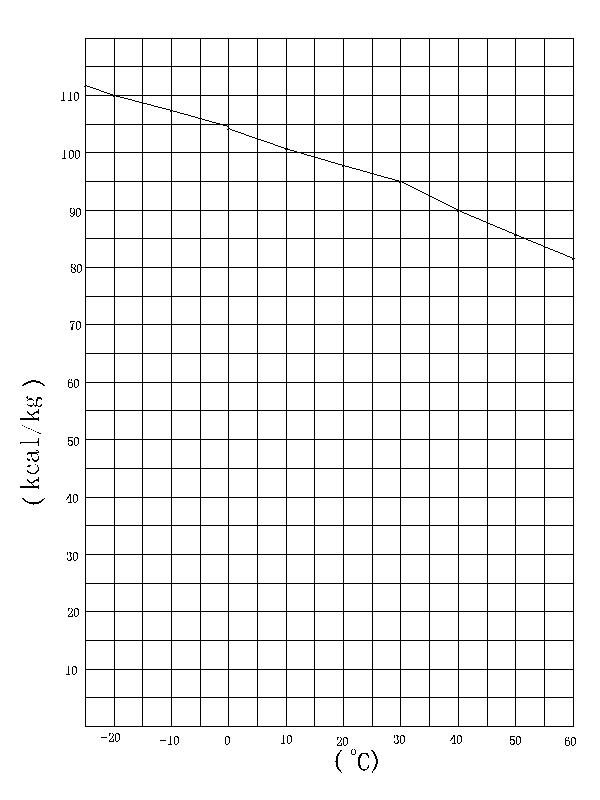

[0050] 2. 114kg×100kcal / kg=11400kcal, 11400kcal÷7000 kcal / ton=1.63 tons (ice), which can meet the freshness of small seafood;

[0051] The above calculation process is based on the national standard GB50072-2001 of the People's R...

Embodiment 2

[0055] A fishery base in the East China Sea has thousands of fishing and aquatic product processing vessels in offshore waters. The typical power of the vessel is 500kw. Each voyage takes 15-21 days and must carry 40-45 tons of fuel.

[0056] 1. After the diesel engine is changed to a dimethyl ether gas engine, 2.3 tons of dimethyl ether is vaporized per day;

[0057] 2. 2300kg / day×100kcal / kg=230,000 kcal÷7000 kcal / ton=32.86 tons / day (ice) can satisfy fresh-keeping refrigeration.

[0058] 3. Fuel costs can be saved by 2 million yuan per ship throughout the year, and 2,000 ships can save fuel costs by about 4 billion yuan per year.

[0059] 4. The environment and atmosphere of offshore waters are protected.

Embodiment 3

[0061] There are several 5,000-ton refrigerated ships in a coastal city. In addition to one 2,000kw main engine, three 200kw auxiliary engines, power generation and refrigeration are added.

[0062] The main engine consumes 320kg / H of diesel oil per hour and produces 3736.32m of flue gas 3 / H;

[0063] The flue gas volume produced by the three auxiliary machines is 1352.1 m3 / H; the total flue gas volume produced by the main and auxiliary machines is 5088.42 m3 per hour 3 / H;

[0064] After changing to a dimethyl ether gas engine, the flue gas volume of the main engine per hour is 2237.8 m 3 / H, as long as one gas generator is working, the flue gas produced is 269.93 m 3 / H, so the total smoke volume is only 2507.73 m 3 / H.

[0065] Due to a main engine and an auxiliary engine, the dimethyl ether consumed per hour is 358.6kg / H, and the heat flow of 35860kcal can be obtained when the liquid is vaporized. The refrigerated room of the ship is 2000m 2 ×2, the total net area i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com