Method for preparing nano MgO sustained-release sterilizing granules

A nano-particle technology, applied in botany equipment and methods, disinfectant, microsphere preparation, etc., can solve the problem of high pH value of nano-MgOp, and achieve the effect of easy control of conditions, simple operation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nanometer MgO sustained-release disinfection particles, the steps are as follows:

[0030] 1) Dissolve 0.5 g of fat-soluble chitosan in 100 mL of acetic acid aqueous solution with a concentration of 1% by volume at 100 °C, add 4.8 g of CaCl after cooling to room temperature 2 2H 2 O, after fully dissolving, adjust the pH value to 5.0-5.5 with a concentration of 1mol / L NaOH aqueous solution to obtain a chitosan solution;

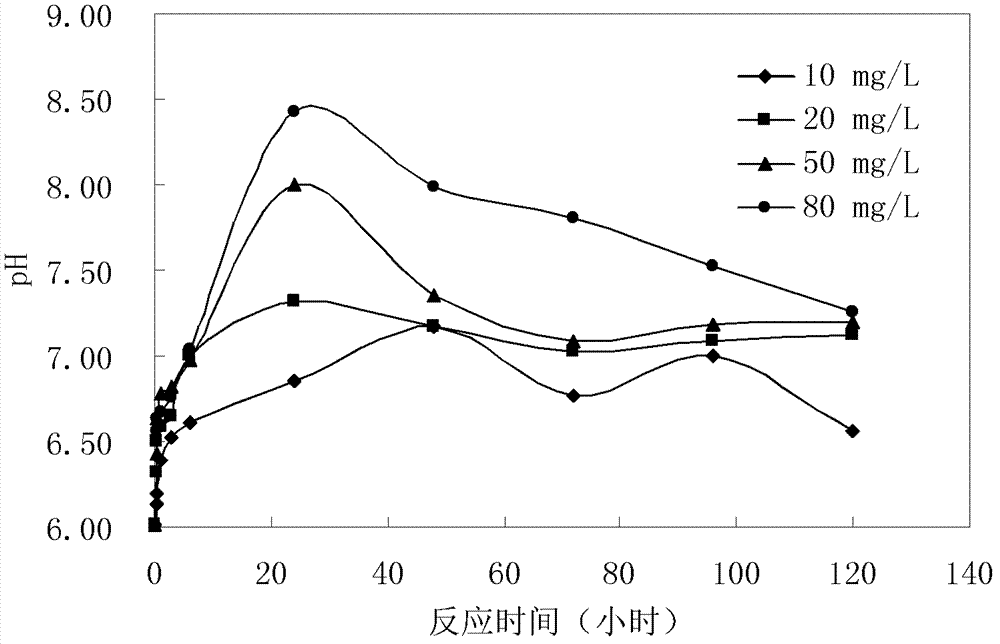

[0031] 2) Prepare a sodium alginate aqueous solution with a concentration of 12mg / mL, add 0.1 g of nano-MgO powder, the average particle size of the nano-MgO powder is 10-80nm, and the specific surface area is 30-50m 2 / g, make nano MgO turbid liquid;

[0032] 3) Drop the nano-MgO turbid solution into the chitosan solution at a rate of 2-3 drops / second. After the addition is completed, stir the above reaction solution at a speed of 1000-1200 rpm for half an hour, discard the liquid to obtain milky white microspheres;

[0033]...

Embodiment 2

[0038] A preparation method of nanometer MgO sustained-release disinfection particles, the steps are as follows:

[0039] 1) Dissolve 0.7g of fat-soluble chitosan in 100mL of acetic acid aqueous solution with a concentration of 2% by volume at 100°C, add 3.6g of CaCl after cooling to room temperature 2 2H 2 O, after fully dissolving, adjust the pH value to 5.0-5.5 with a concentration of 1mol / L NaOH aqueous solution to obtain a chitosan solution;

[0040] 2) Prepare a sodium alginate aqueous solution with a concentration of 12mg / mL, add 0.3g of nano-MgO powder, the average particle size of the nano-MgO powder is 10-80nm, and the specific surface area is 30-50m 2 / g, make nano MgO turbid liquid;

[0041] 3) Drop the nano-MgO turbid solution into the chitosan solution at a rate of 2-3 drops / second. After the addition is completed, stir the above reaction solution at a speed of 1000-1200 rpm for half an hour, discard the liquid to obtain milky white microspheres;

[0042] 4) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com