High-selectivity dry etching method for HfO2 thin film

A high-selectivity, dry etching technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inaccurate setting of the etching end point and low HfO2 selection, and achieve good etching effect, Improved accuracy, high selectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

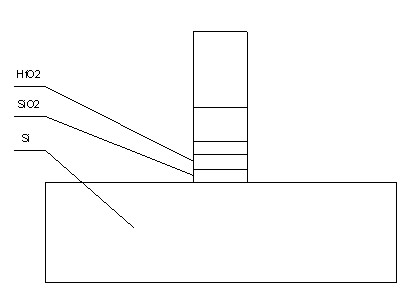

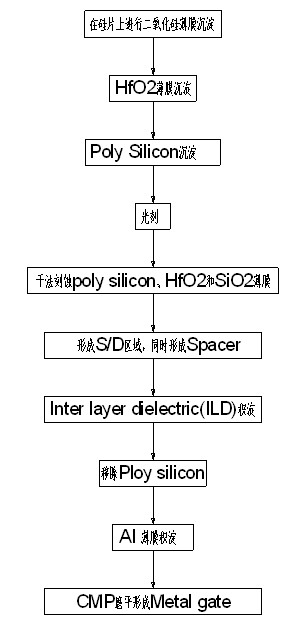

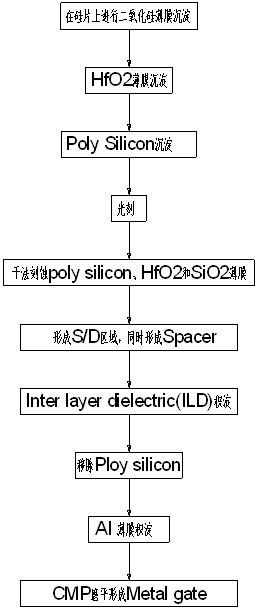

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] A kind of highly selective dry etching method to HfO2 film, wherein,

[0021] Step a: In an etching device, the HfO2 film on the substrate is etched with a mixed gas composed of BCl3 gas and H-containing gas, wherein the BCl3 gas reacts with the HfO2 film to generate volatile by-products.

[0022] Further, the BCl3 gas reacts with the HfO2 film to generate a stable volatile product (BOCl) 3, and the highly selective dry etching of the high-k material HfO2 film is realized by using the BCl3 plasma.

[0023] The etching equipment described in the present invention can be selected from CCP, TCP, ICP or RIE equipment, and dry etching is carried out by gas mixed with BCl3 plasma fonts in the above equipment.

[0024] During the etching process of step a and step b, the etching temperature can be controlled between 150°C and 300°C, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com