Direct-current ice-melting isolating switch

A technology for isolating switches and direct current melting ice, which is applied in the direction of electric switches, high-voltage air circuit breakers, electrical components, etc., and can solve problems such as high cost, large investment, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

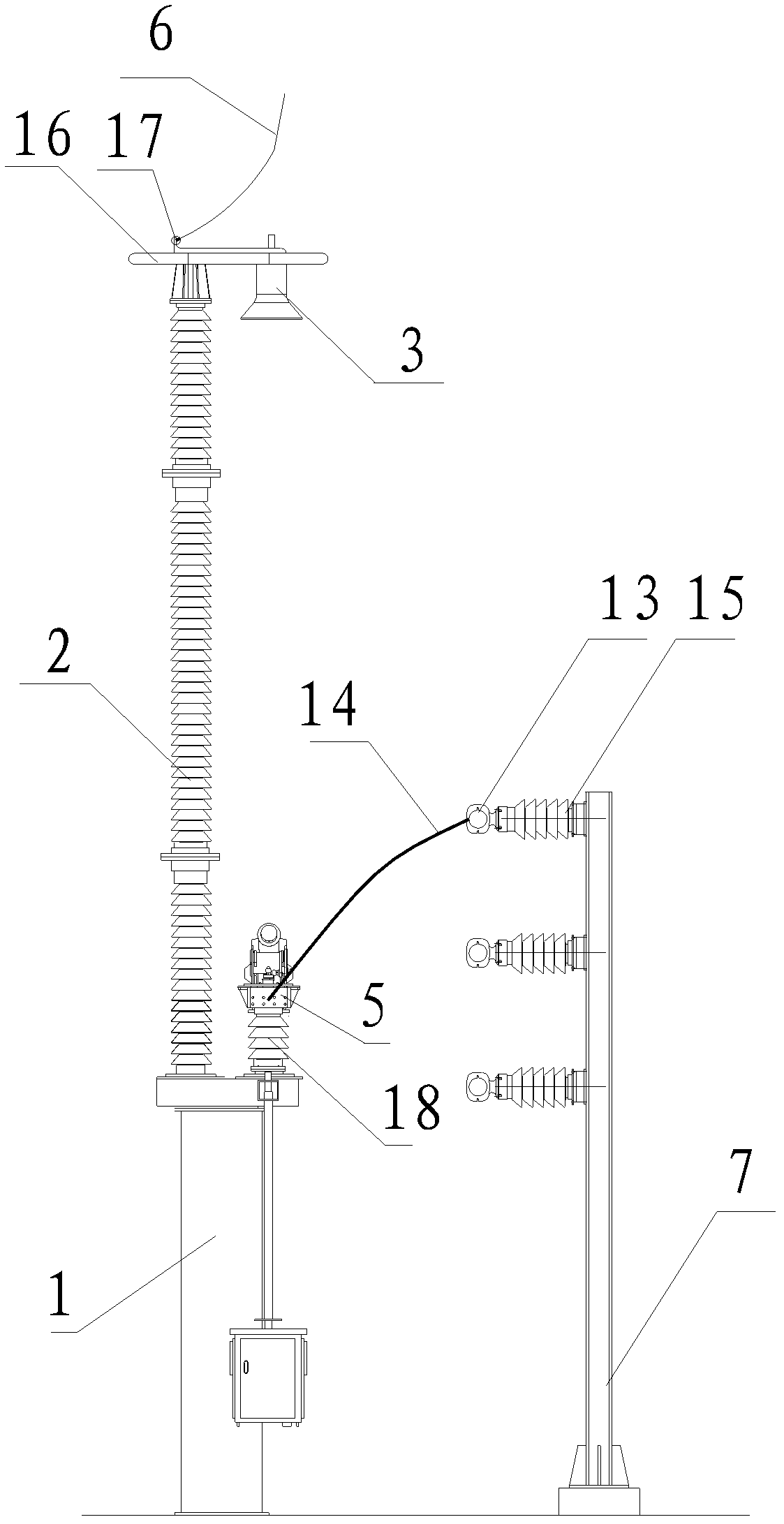

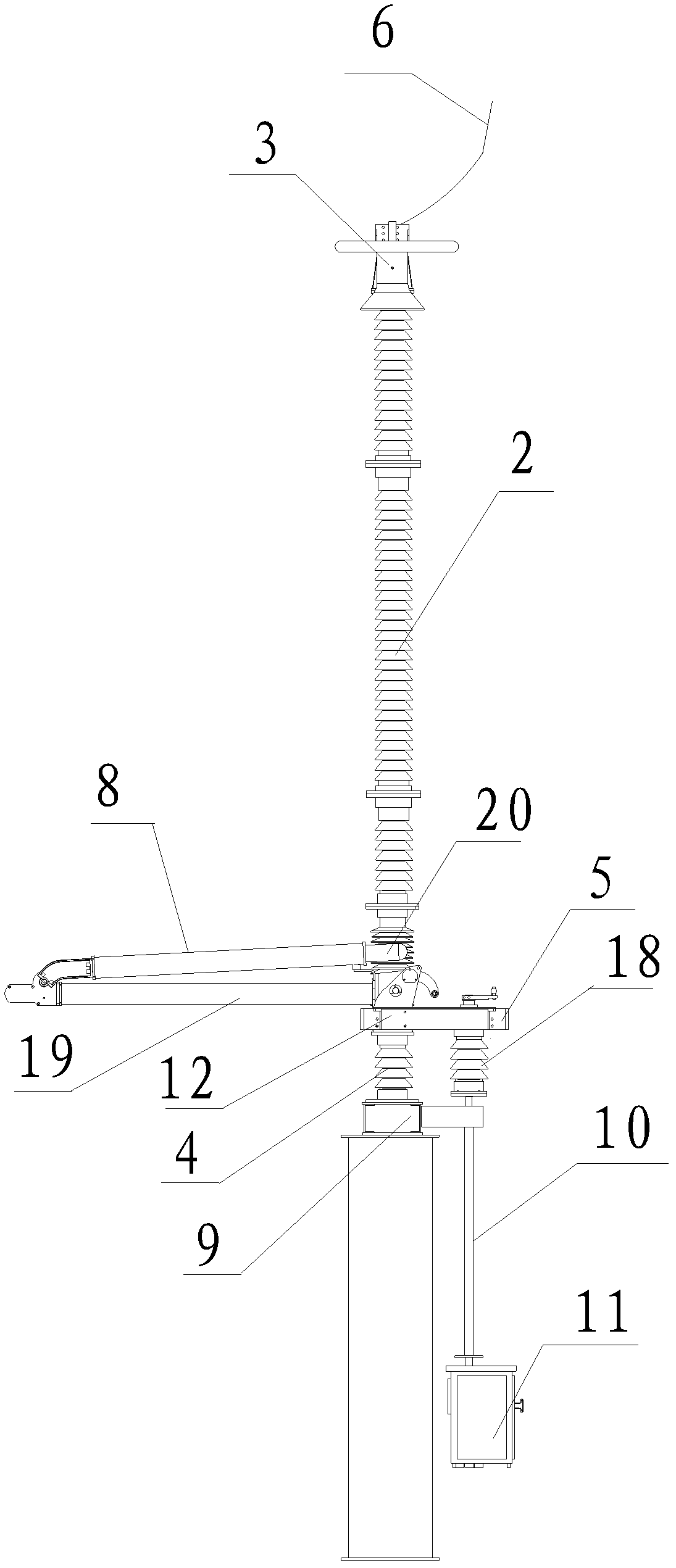

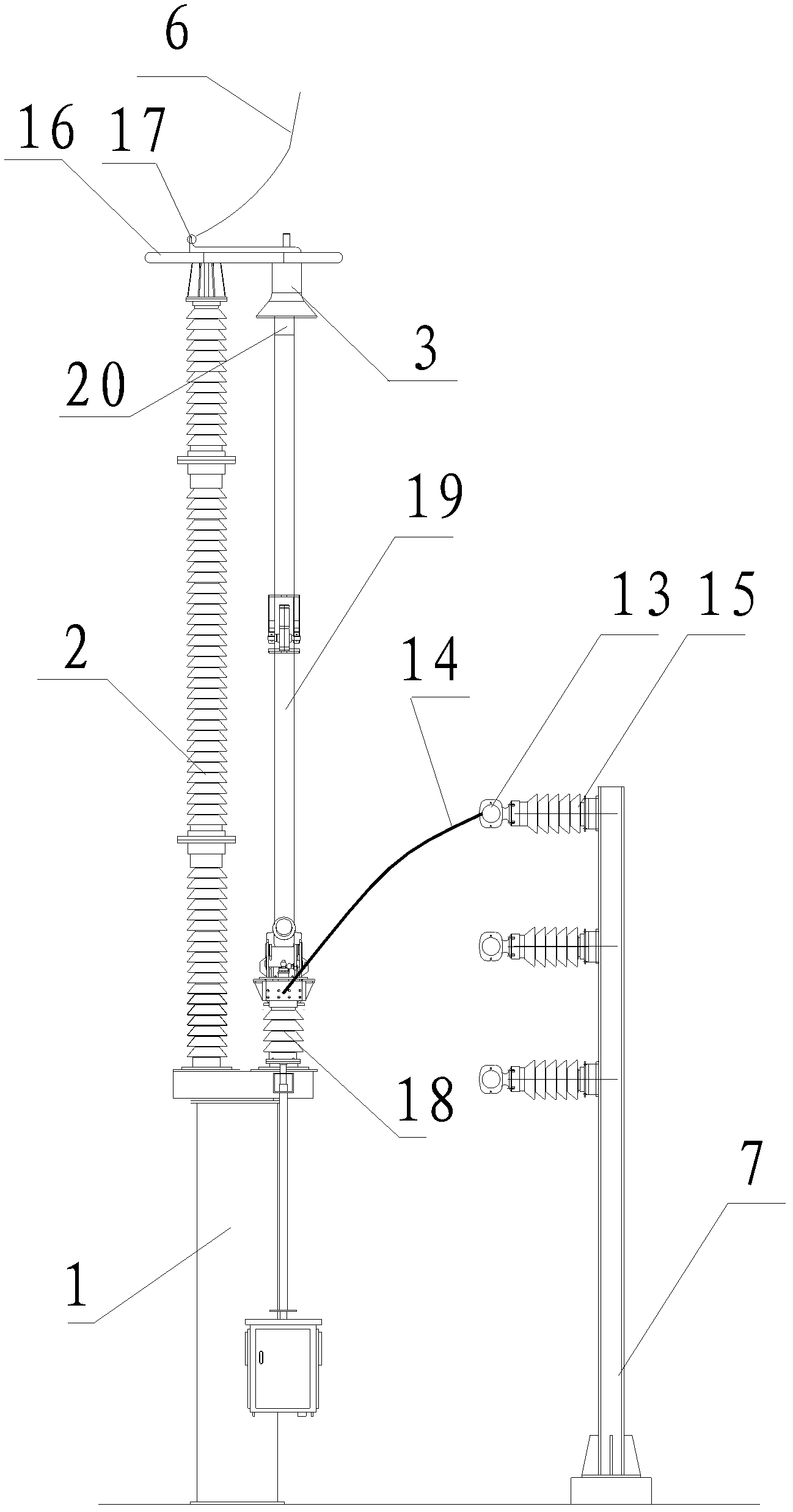

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The DC deicing isolating switch and the DC bus support 7 of the present invention are installed on the outlet side of the high-voltage power distribution device in the substation.

[0026] A group of AC post insulators 2 are installed on the isolating switch bracket 1 , and a voltage equalizing ring 16 is installed on the upper end of the AC post insulators 2 . The static contact 3, the AC connection terminal 17 and the pressure equalizing ring 16 are connected as a whole. The AC connection terminal 17 is connected to the power transmission line by being connected to the AC connection wire 6 .

[0027] In this embodiment, the conductive knife switch 8 adopts the conductive knife switch structure of an electric single-arm vertical telescopic isolating switch, including a conductive rod 19 , a conductive base 12 , an operating insulator 18 , an operating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com