Maintaining and running state control method of anode roasting furnace

An anode roasting furnace and operating status technology, which is applied to furnace control devices, furnaces, furnace components, etc., can solve problems such as affecting production costs, inability to maintain the fire path of the roasting furnace, tracking the running status, feedback, and affecting the quality of roasted products, etc. To achieve the effect of quality control and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below, but the protection scope of the present invention is not limited by the embodiments.

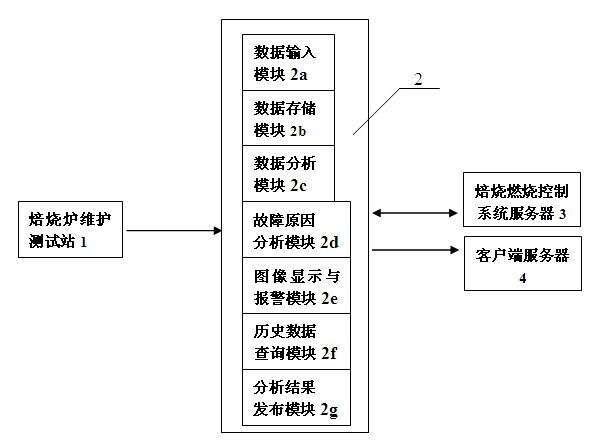

[0017] As shown in the figure, an anode roaster maintenance and operation status control method of the present invention, before the roaster furnace chamber is installed, the roaster maintenance test station 1 tests the deformation, bending and collapse data of the roaster fire path, and passes the data through data processing With the data input module 2a, data storage module 2b, data analysis module 2c, failure cause analysis module 2d, color display and alarm module 2e, historical data query module 2f and analysis result release module 2g in the analysis server 2, each fire of the roasting furnace is completed. The input, classification and storage of channel measurement data, data analysis, failure cause analysis, and history query of channel color display and alarm, and release the above analysis results to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com