Cadaverine-producing engineering strain

A technology of engineering bacteria and genetically engineered bacteria, which is applied in the direction of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of low cadaverine synthesis, inability to transport cadaverine, inability to synthesize lysine in large quantities, etc., and achieve a huge economy Benefits and practical benefits, broad market development prospects, the effect of curbing global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

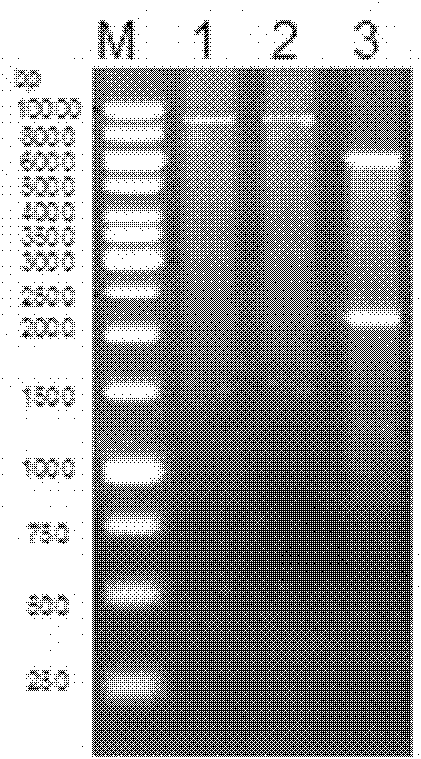

[0034] A cadaverine engineering bacterium, the host bacterium is Corynebacterium glutamicum (including but not limited to Corynebacterium glutamicum ATCC13032), which has a lysine decarboxylase gene and a lysine-cadaverine antiporter gene. The lysine decarboxylase gene and the lysine-cadaverine antiporter gene are heterologous to the engineering bacteria. The lysine decarboxylase gene is derived from Hafnia alvei. The lysine-cadaverine antiporter gene is derived from Escherichia coli. The size of the lysine decarboxylase gene is 2220bp, and its sequence is sequence 1; the lysine-cadaverine antiporter gene is 1335bp, and its sequence is sequence 4.

[0035] Wherein, the lysine decarboxylase gene and the lysine-cadaverine antiporter gene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com