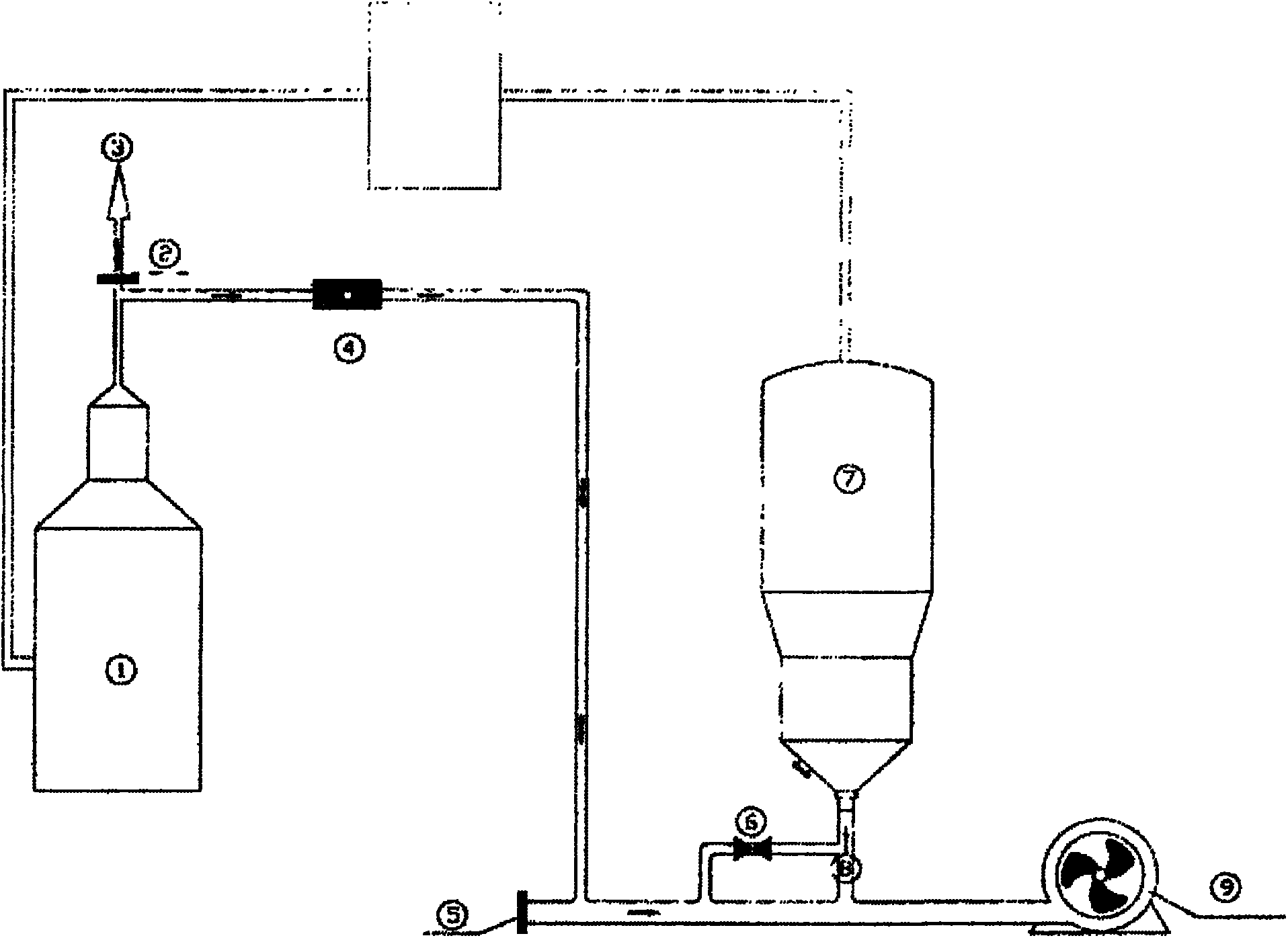

Recycling method of tail gas from pyrolusite reduction and sulfuric acid coproduction in fluidized bed furnace

A technology of tail gas circulation and boiling furnace, applied in manganese sulfate, chemical instruments and methods, sulfur compounds, etc., can solve the problems of poor operating conditions, environmental pollution, high labor intensity, etc. good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

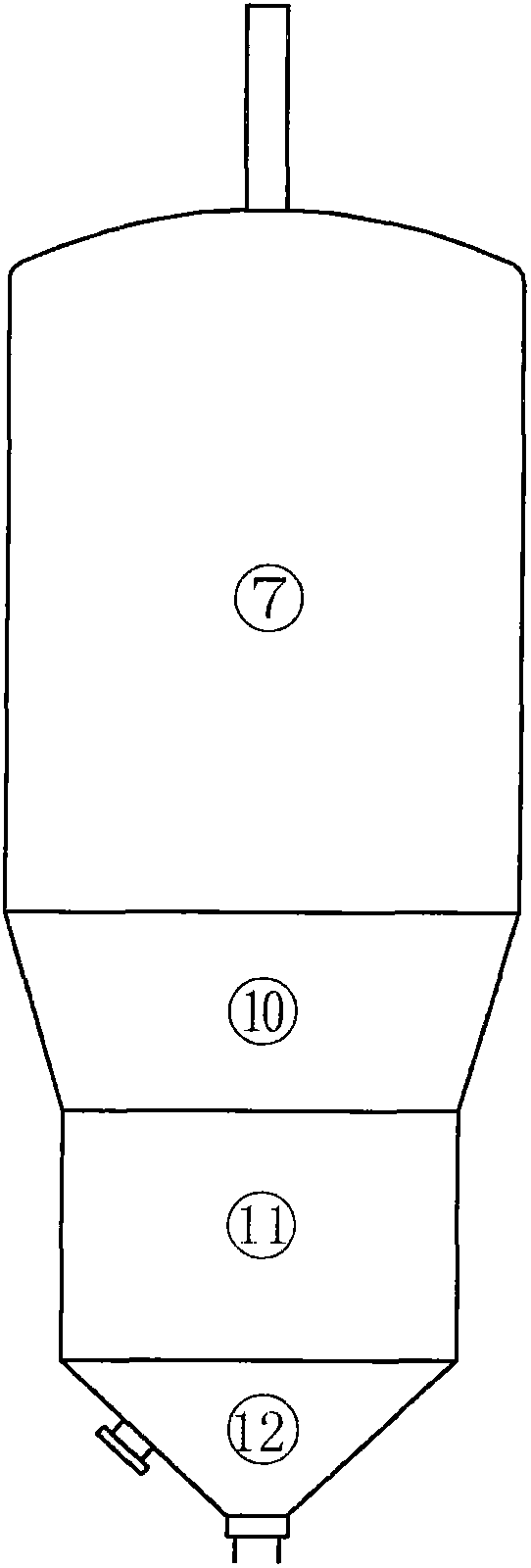

Method used

Image

Examples

Embodiment 1

[0032] Mix 500kg of sulfur and 250kg of pyrolusite (proportion 1:0.5) into the fluidized fluidized furnace, and blow air into the lower part of the fluidized fluidized furnace to make the material boil and burn in the fluidized fluidized furnace under the action of the furnace bottom airflow and the negative pressure on the furnace top. , control the temperature of the boiling layer at about 850-950, control the oxygen content in the lower section of the fluidized furnace at about 10%, the sulfur mixed in the pyrolusite is burned to generate sulfur dioxide, and a large amount of heat is generated to reduce the manganese dioxide in the pyrolusite to manganese monoxide. Manganese monoxide is directly discharged into sulfuric acid solution (or electrolytic manganese anolyte) to slurry and leach manganese sulfate, and the content of manganese sulfate is determined by conventional methods. The furnace gas in the lower section lacks oxygen and contains sublimated sulfur. Air is blown...

Embodiment 2

[0035] Embodiment 2: no longer narrate with the similarity of embodiment 1, difference is:

[0036] 400kg of sulfur and 800kg of pyrolusite (proportion 1:2) are mixed and sent into the fluidized furnace, the temperature of the fluidized layer is controlled to 750-850°C, and the outlet temperature of the fluidized furnace is 800-850°C. At this time, the concentration of sulfur dioxide at the outlet of the fluidized furnace is 10-13%. The furnace gas is sent to the purification process after dedusting, and the furnace gas is sent to the purification process after dedusting. The sulfur dioxide is catalyzed by the catalyst to form sulfur trioxide, which reacts with water to generate sulfuric acid. Part of the unabsorbed furnace gas is used as tail gas and mixed with air. Reconnect to the lower part of the fluidized fluidized furnace, and control the oxygen content at 9.5% by adjusting the tail gas valve, and the ratio of tail gas to air is 1:1.2. The output of manganese monoxide i...

Embodiment 3

[0037] Embodiment 3: no longer narrate with the similarity of embodiment 1, difference is:

[0038] 400kg of sulfur and 1600kg of pyrolusite (proportion 1:4) are mixed and sent into the fluidized furnace, the temperature of the fluidized layer is controlled at 600-700°C, and the outlet temperature of the fluidized furnace is 700-800°C. At this time, the concentration of sulfur dioxide at the outlet of the fluidized furnace is 10-13%. The furnace gas is sent to the purification process after dedusting, and the furnace gas is sent to the purification process after dedusting. The sulfur dioxide is catalyzed by the catalyst to form sulfur trioxide, which reacts with water to generate sulfuric acid. Part of the unabsorbed furnace gas is used as tail gas and mixed with air. Reconnect to the lower section of the fluidized fluidized furnace, and control the oxygen content at 9.8% by adjusting the tail gas valve, and the ratio of tail gas to air is 1:1.4. The output of manganese monoxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com