Apparatus and method for preparing high-activity calcium hydroxide by using carbide slag alkali residue

A calcium carbide slag, high activity technology, applied in separation methods, chemical instruments and methods, and solid waste removal, etc., can solve the problems of high operation cost of milling, high return material ratio, small specific surface area, etc., and reduce desulfurization operation. Cost, desulfurization efficiency improvement, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

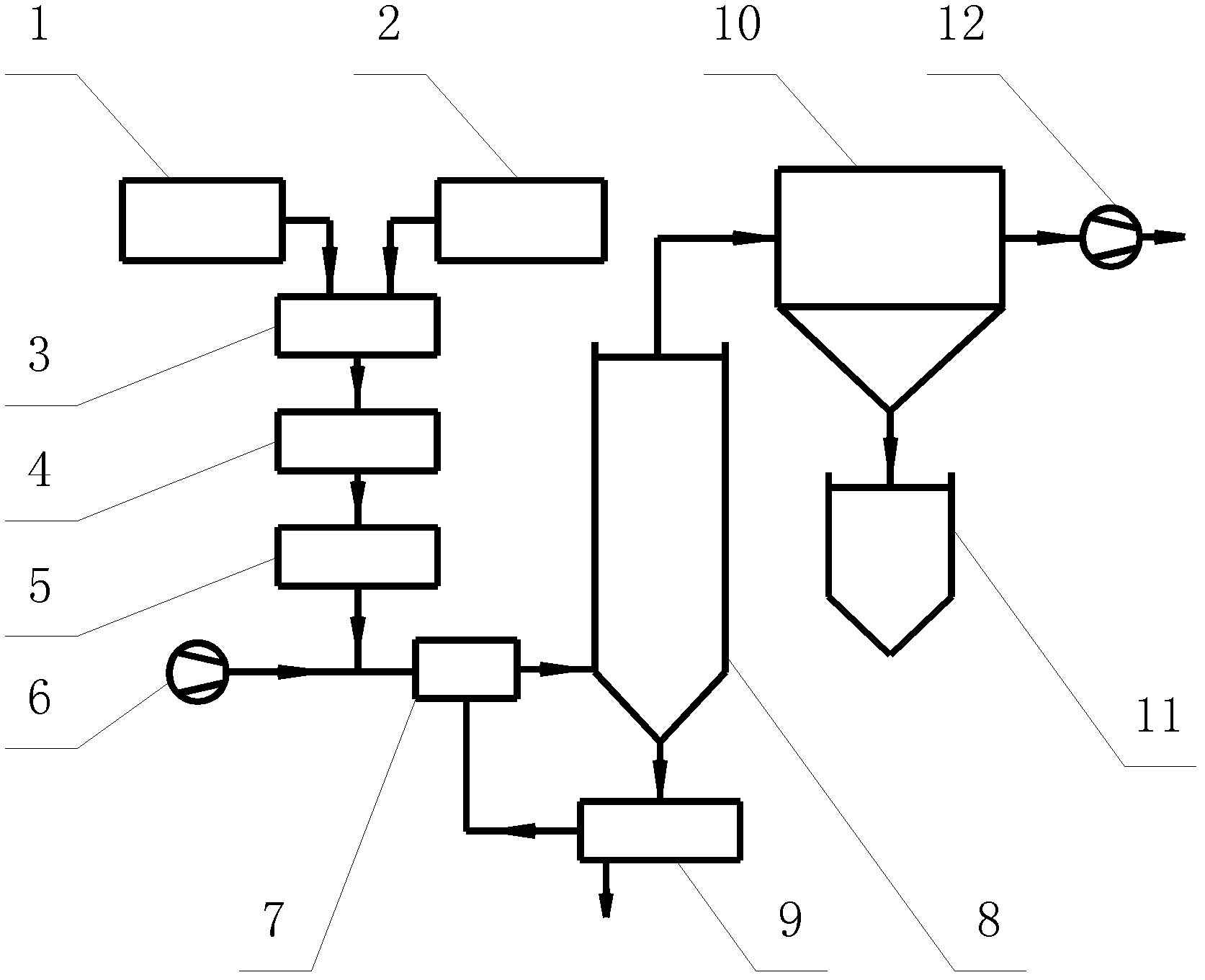

[0019] see figure 1 A device for preparing highly active slaked lime by using calcium carbide slag alkali slag, including sodium bicarbonate metering and dosing equipment 1, calcium carbide slag dosing equipment 2, and also including sequentially connected mixing tanks 3, calcium carbide slag conveying screw 4, dryer 5 , crusher 7, air separator 8, dust collector 10, collection bin 11, the sodium bicarbonate metering and dosing equipment 1, carbide slag dosing equipment 2 are all connected with the mixing tank 3, and the bottom of the air separator 8 There is also a coarse material return screw 9, the outlet of the coarse material return screw 9 is connected with the crusher 7, a blower 6 is also provided between the dryer 5 and the crusher 7, and a dust collector 10 is also connected. The induced draft fan 12 .

[0020] The above-mentioned dust collector 10 is a bag-type dust collector, the above-mentioned mixing tank 3 adopts double-shaft stirring, and the two shafts move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com