Deduster and method for treating haydite kiln tail gas therewith

A technology for dust collectors and air inlets, applied in chemical instruments and methods, waste heat treatment, separation methods, etc., can solve problems such as inconvenient maintenance and replacement, high cost, and reduced efficiency, and achieve simple internal structure and long contact time , easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

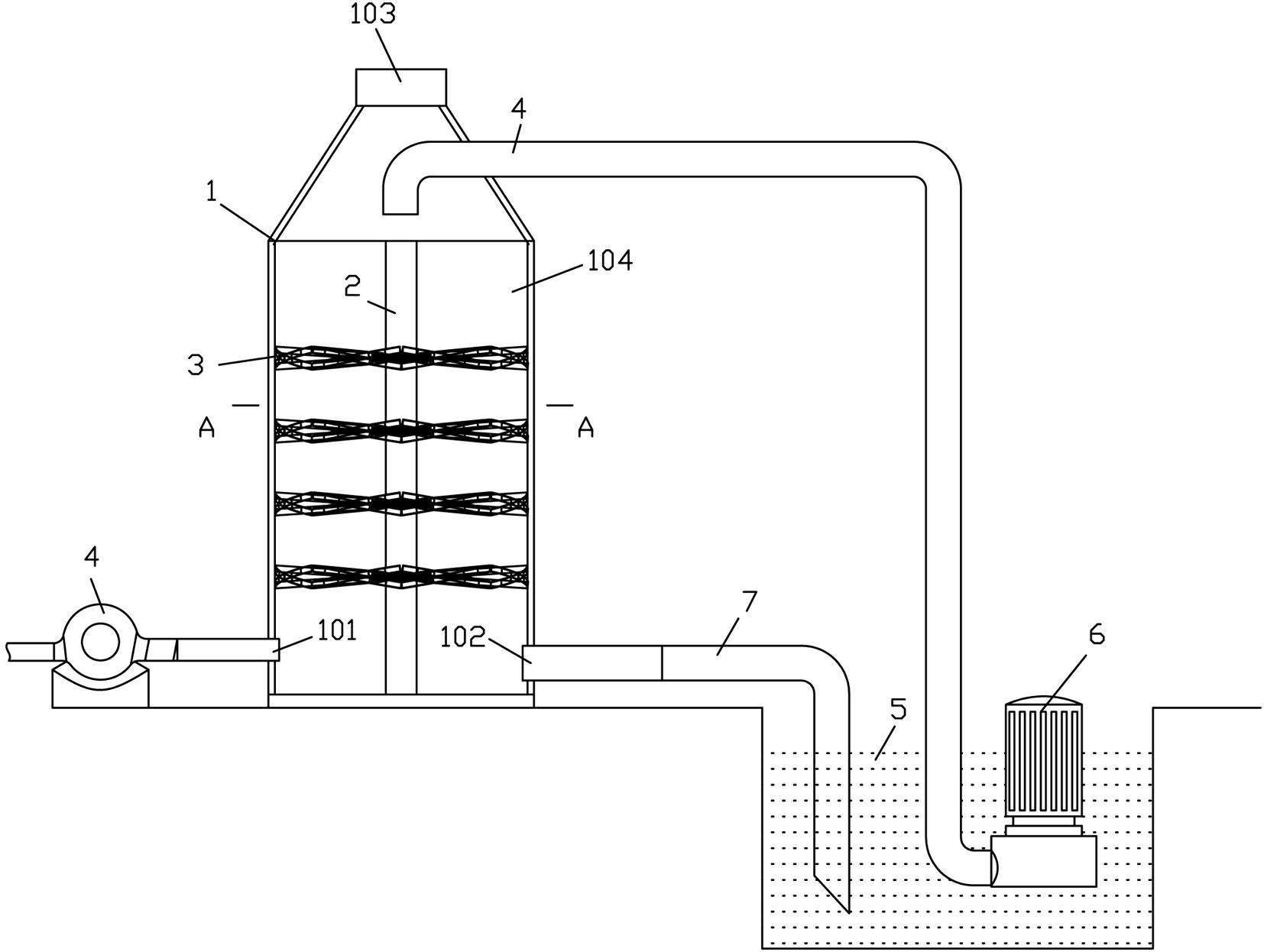

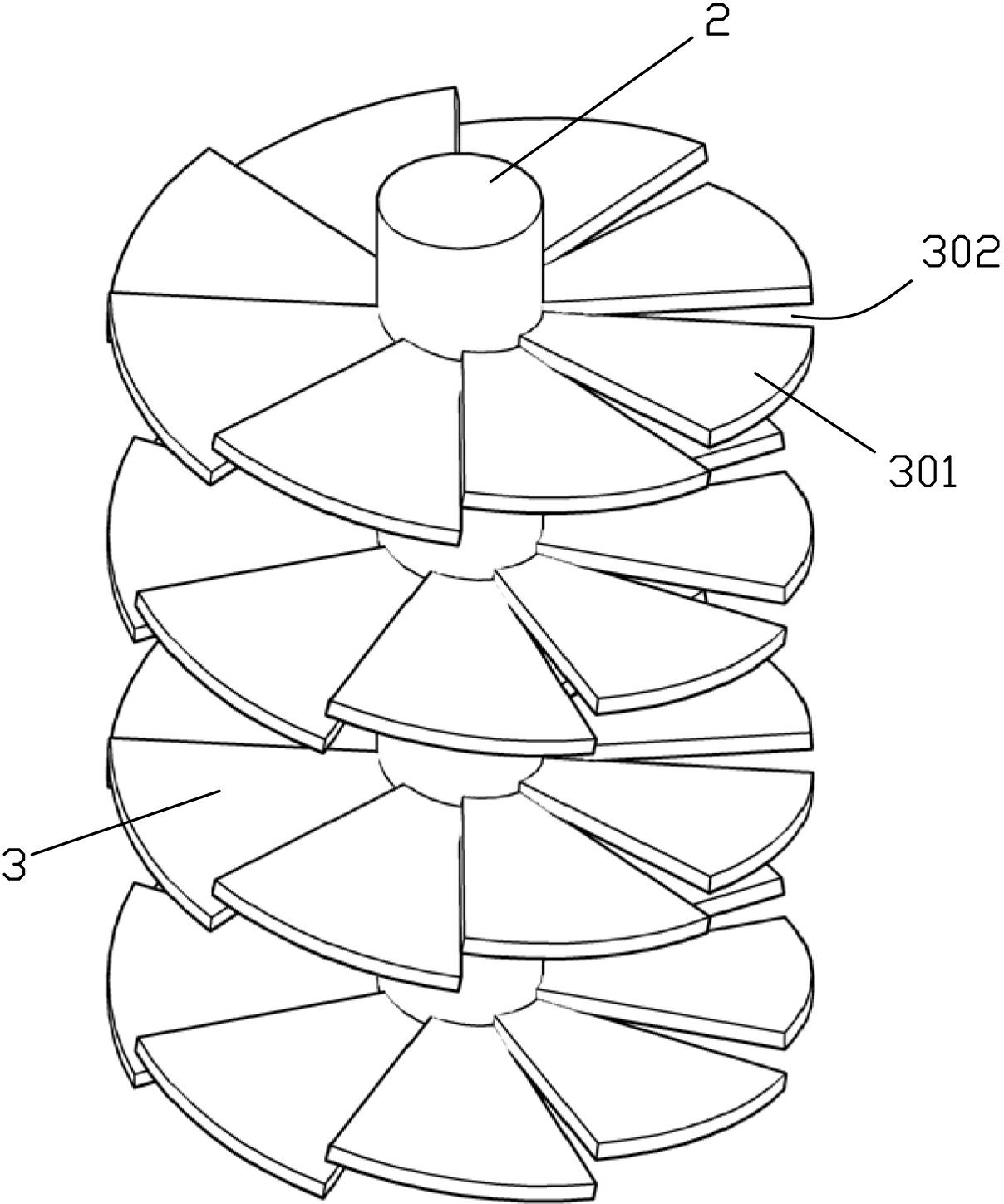

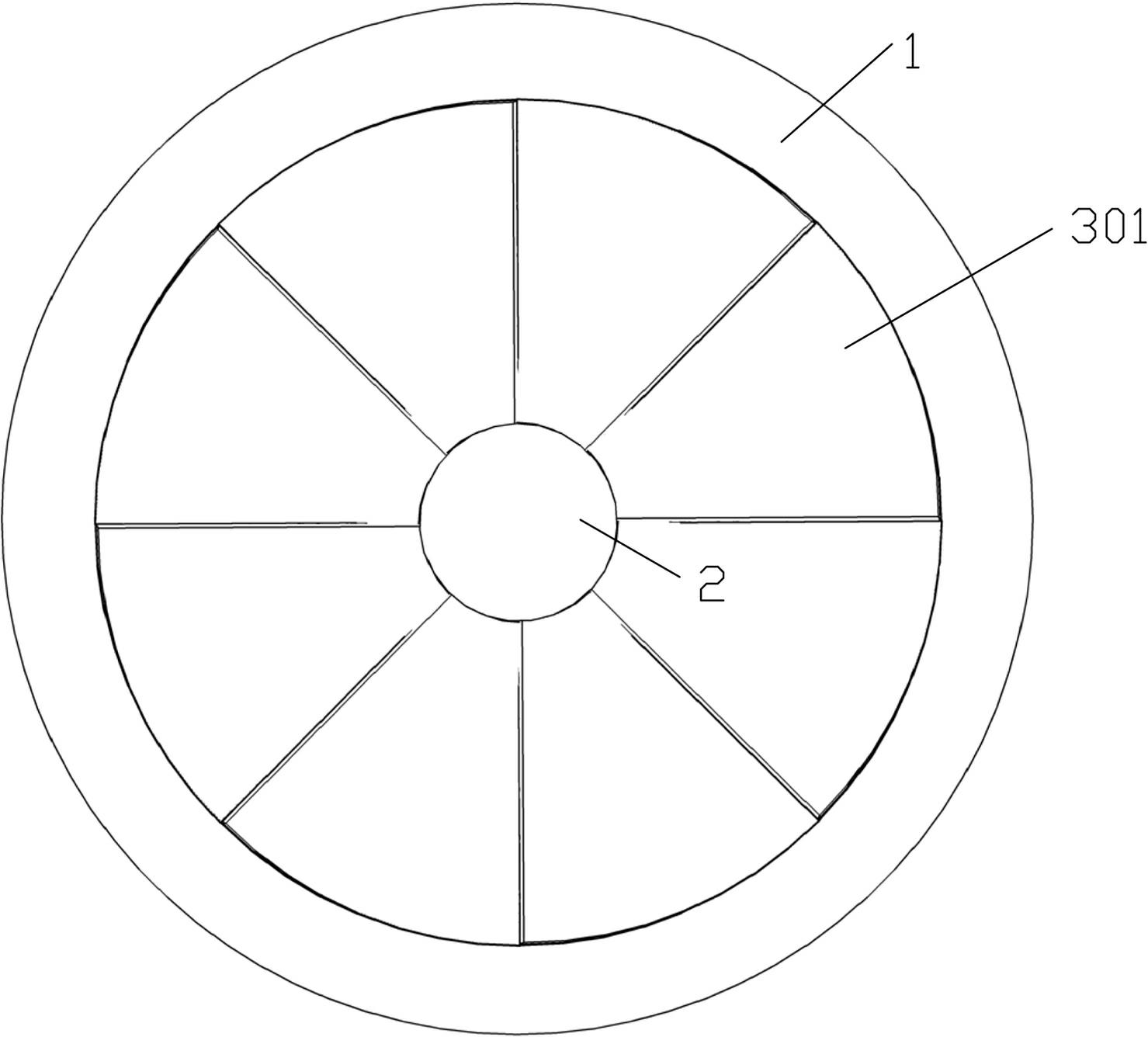

[0035] Examples, see attached figure 1 , 2 , 3, 4, a kind of dust remover, comprises the dust remover shell 1 that has air inlet 101, water outlet 102 and exhaust port 103 and spray pipe 4, pool 5, and a water pump is installed in described pool 5 6. The water pump 6 communicates with the spray pipe 4 . Through this water pump 6, water is supplied to the shower pipe 4, so that the shower pipe 4 can spray out the water needed for dust removal, and the pool 5 also has the function of sedimentation, which can deposit the water after the dust removal from the water outlet 102, And the pool 5 is arranged on the outside of the dust collector cylinder 1, the size can be carried out according to the actual situation, and the cleaning is also very convenient; the air inlet 101 and the water outlet 102 are all opened on the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com